AT2000 universal gas cartridge CFH 600 ml

€5.40*

Content:

0.6 Liter

(€9.00* / 1 Liter)

Available, delivery time: 1-3 days

Product number:

36001

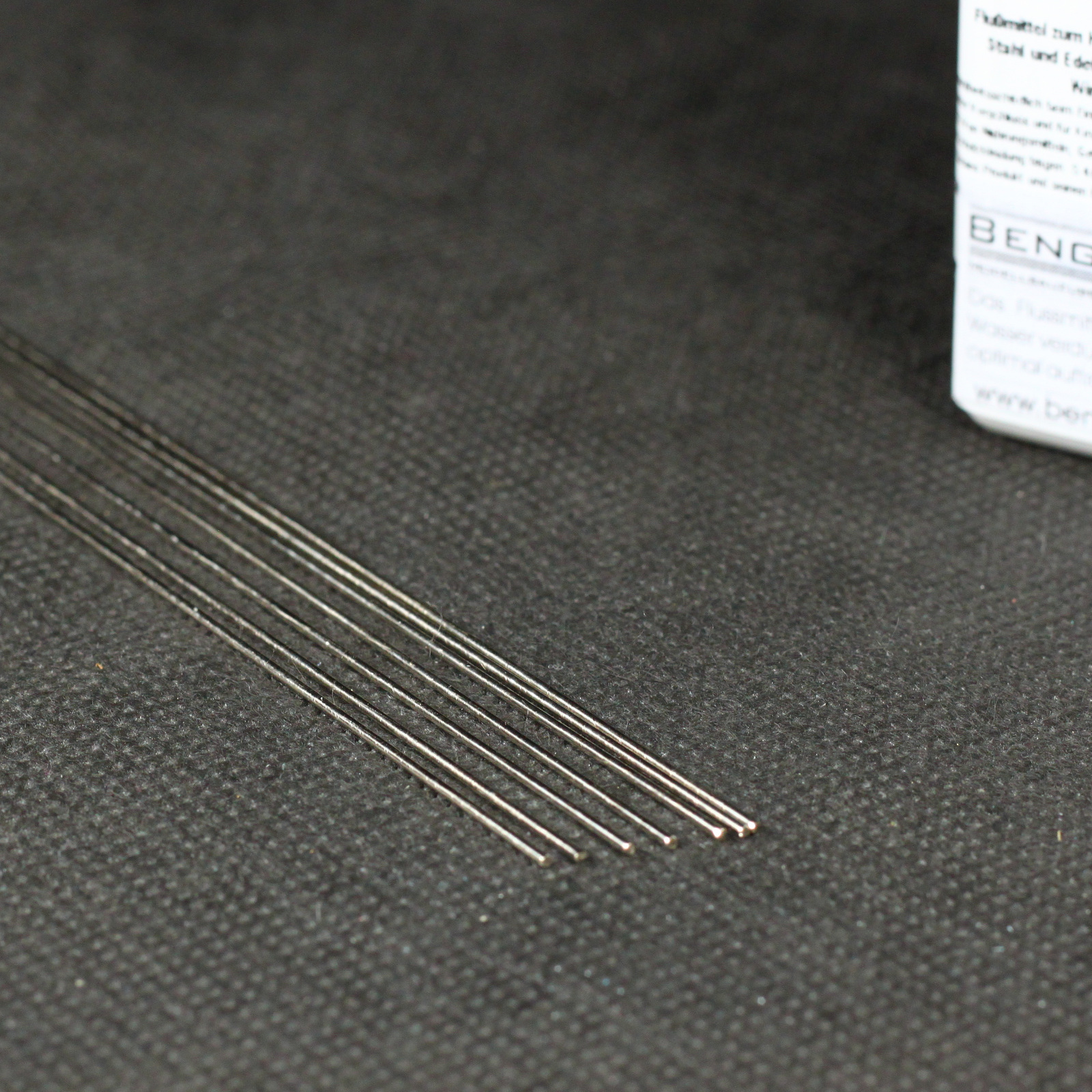

Product information "AT2000 universal gas cartridge CFH 600 ml"

The AT2000 universal gas cartridge fits the CFH turbo burner. With this can you can work with the burner for between 1.5 and 7 hours depending on the flame size. The universal gas cartridge can also be used on other devices such as weed burners or other soldering devices.

- 30% propane, 70% butane.

- Contents 600 ml/ 330g

- Canister type: AT2000 can standardized according to EN 417.

Login