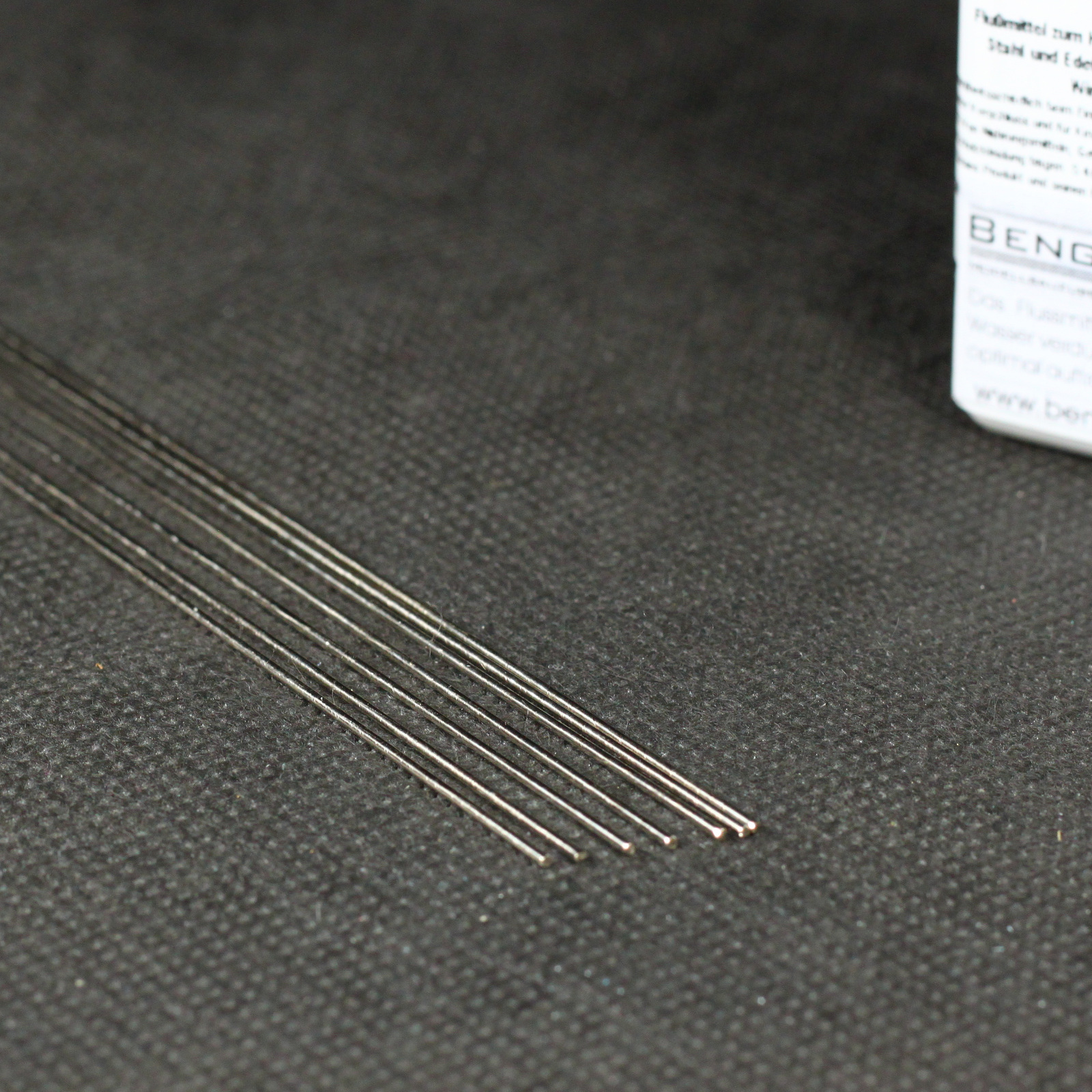

Brass remnants

Product information "Brass remnants"

Fill up your leftover box!!!

With these 800g brass scraps you always have a little spare material on hand.

You get 200g of Ms58 flat material between 2mm and 6mm thick and

600g Ms58 round material between 3mm and 50mm diameter.

The exact composition is of course always different.

Login