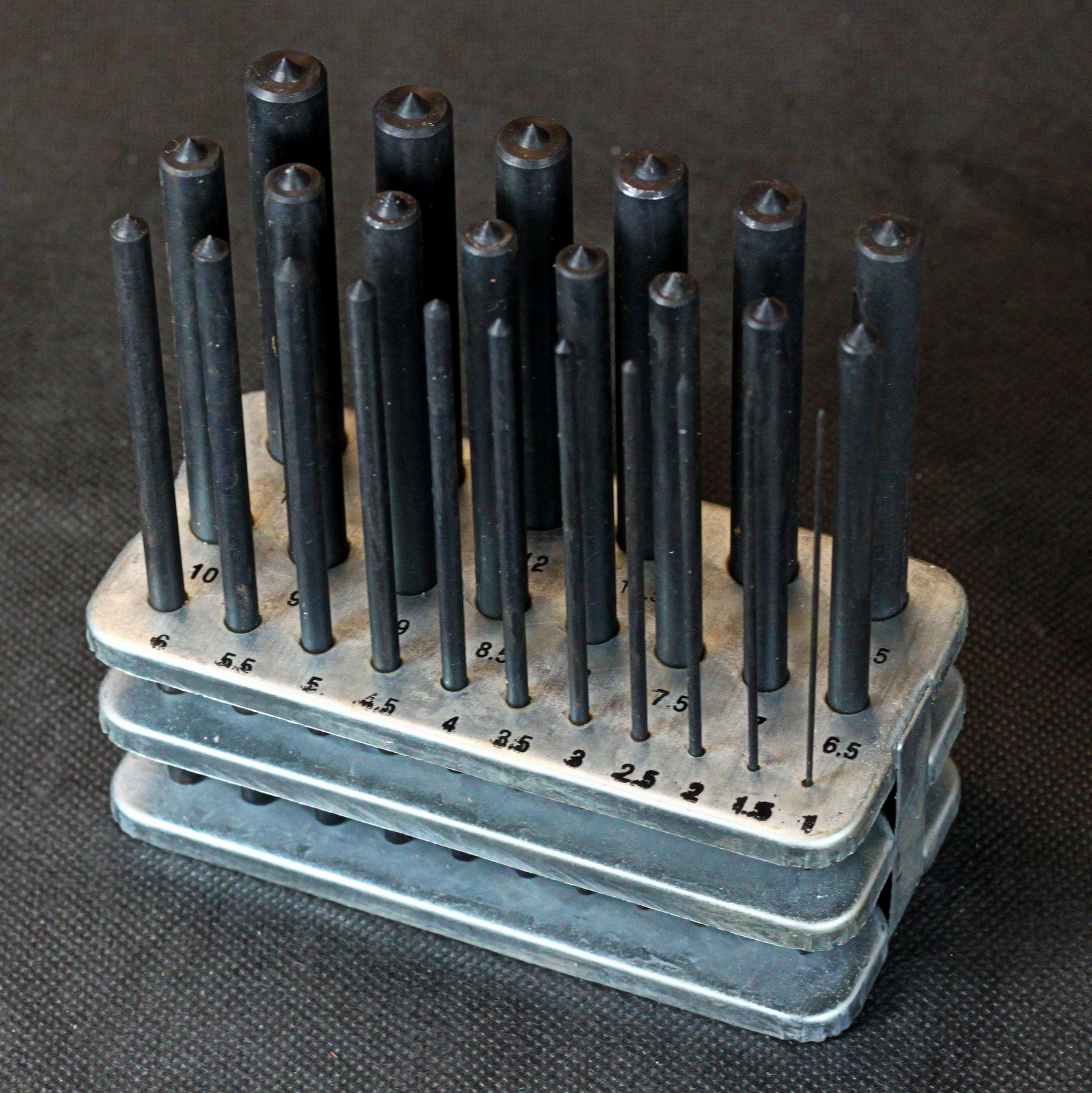

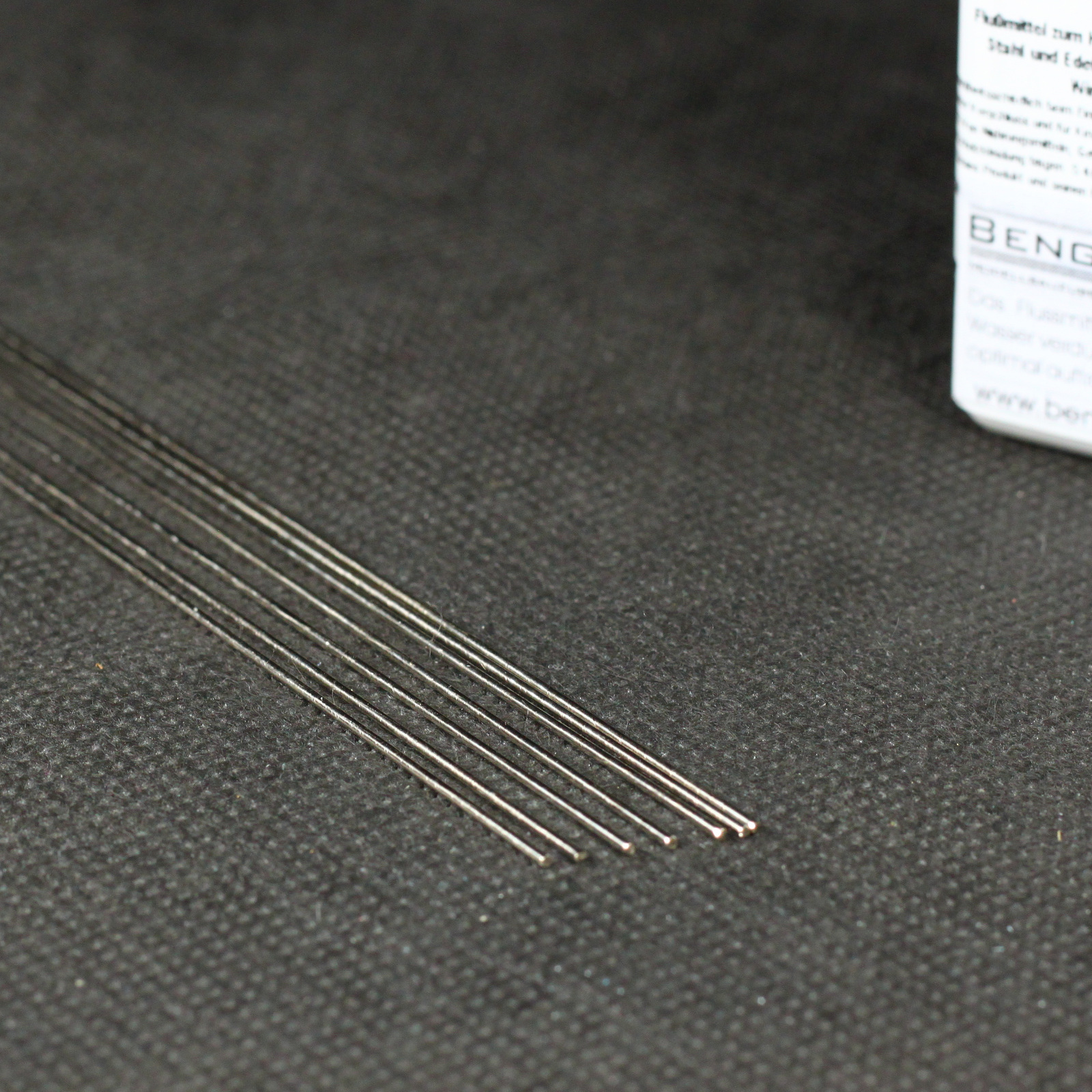

Center punch set

The center punch set consists of 25 center punches made of hardened steel.

The center punches are suitable for transferring holes from one component to another. To do this, a centering center punch is inserted either into the hole of an existing component or into the hole of a template and transferred to the second part. The center punch set is suitable for use in mechanical engineering, steel construction, crafts and hobbies. The grain diameters increase by 0.5mm from 1mm to 13mm. The actual dimensions of the center punches are 0.05mm below standard dimensions. All 25 center punches are 120mm long. The center punches are delivered with a clear metal stand.

Centering center punch set (25 pieces) from 1mm to 13mm 0.5mm increments

Login