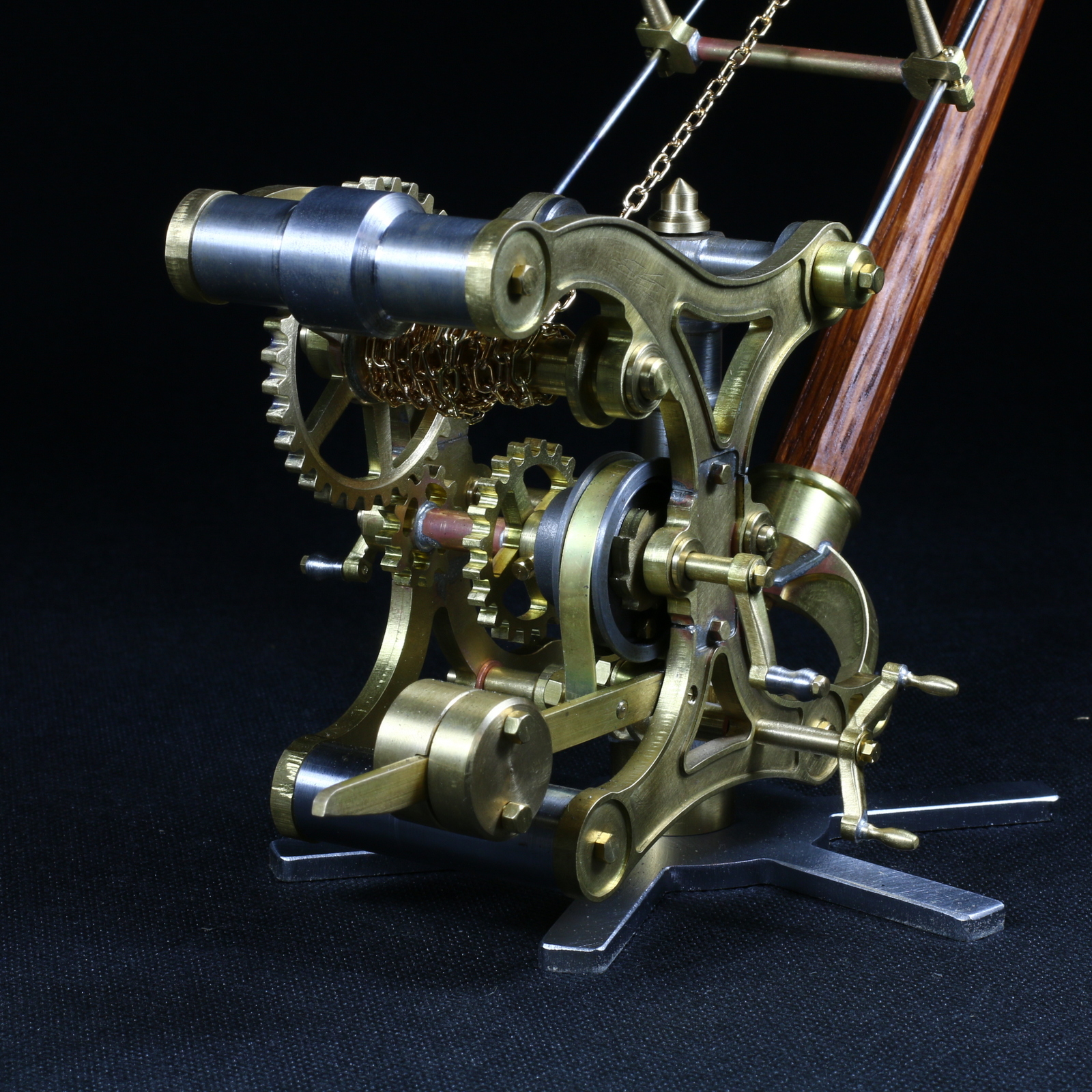

Harbor Crane Hercules

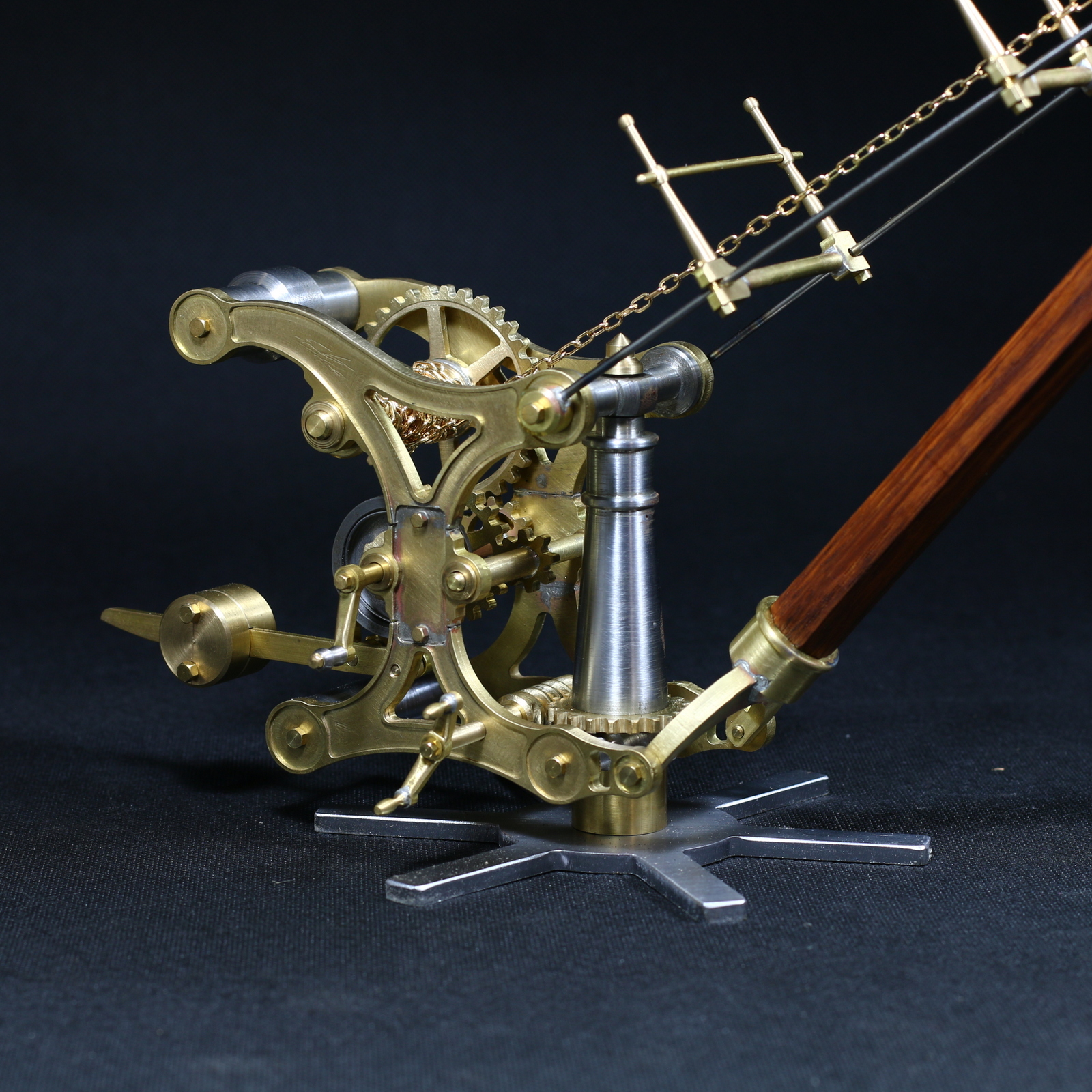

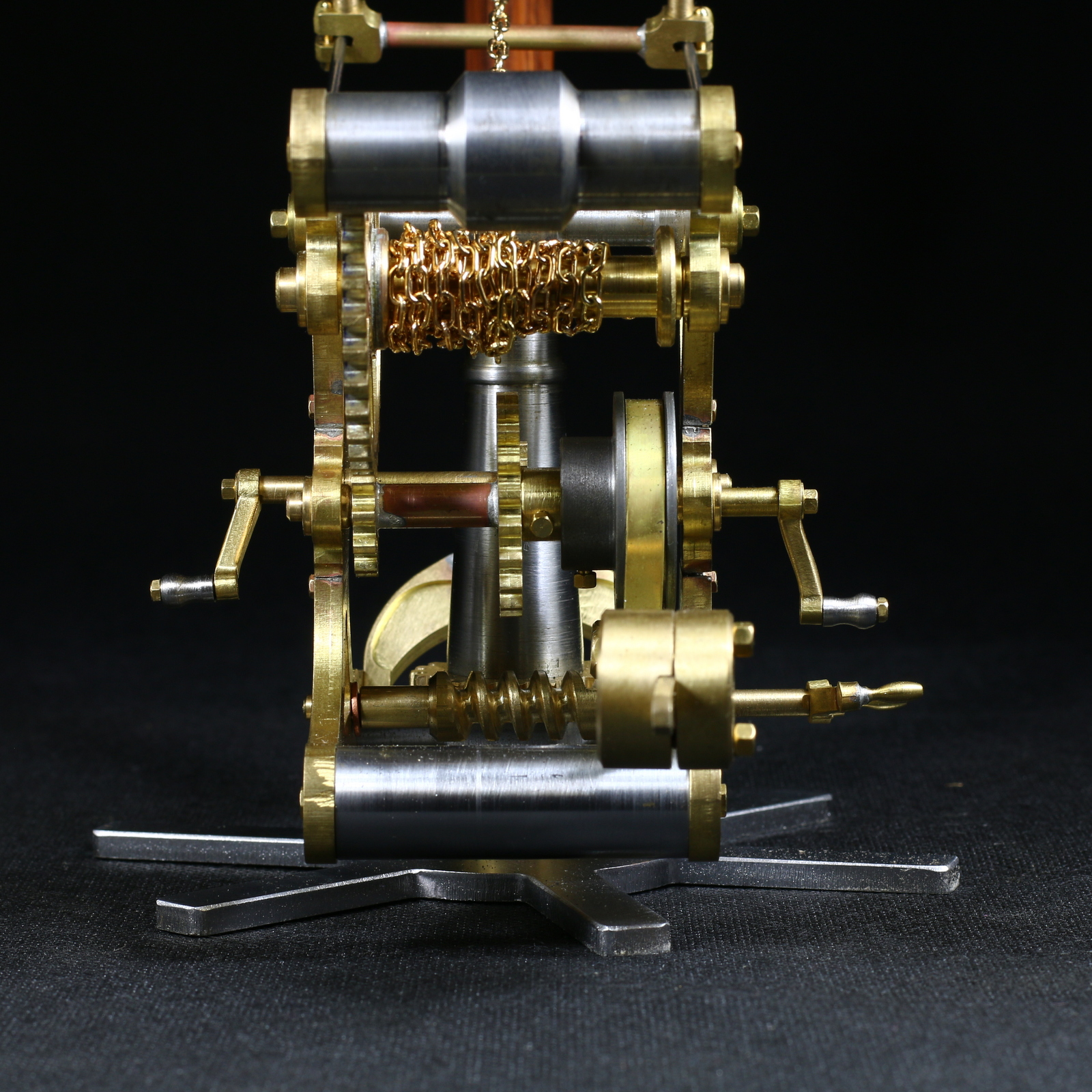

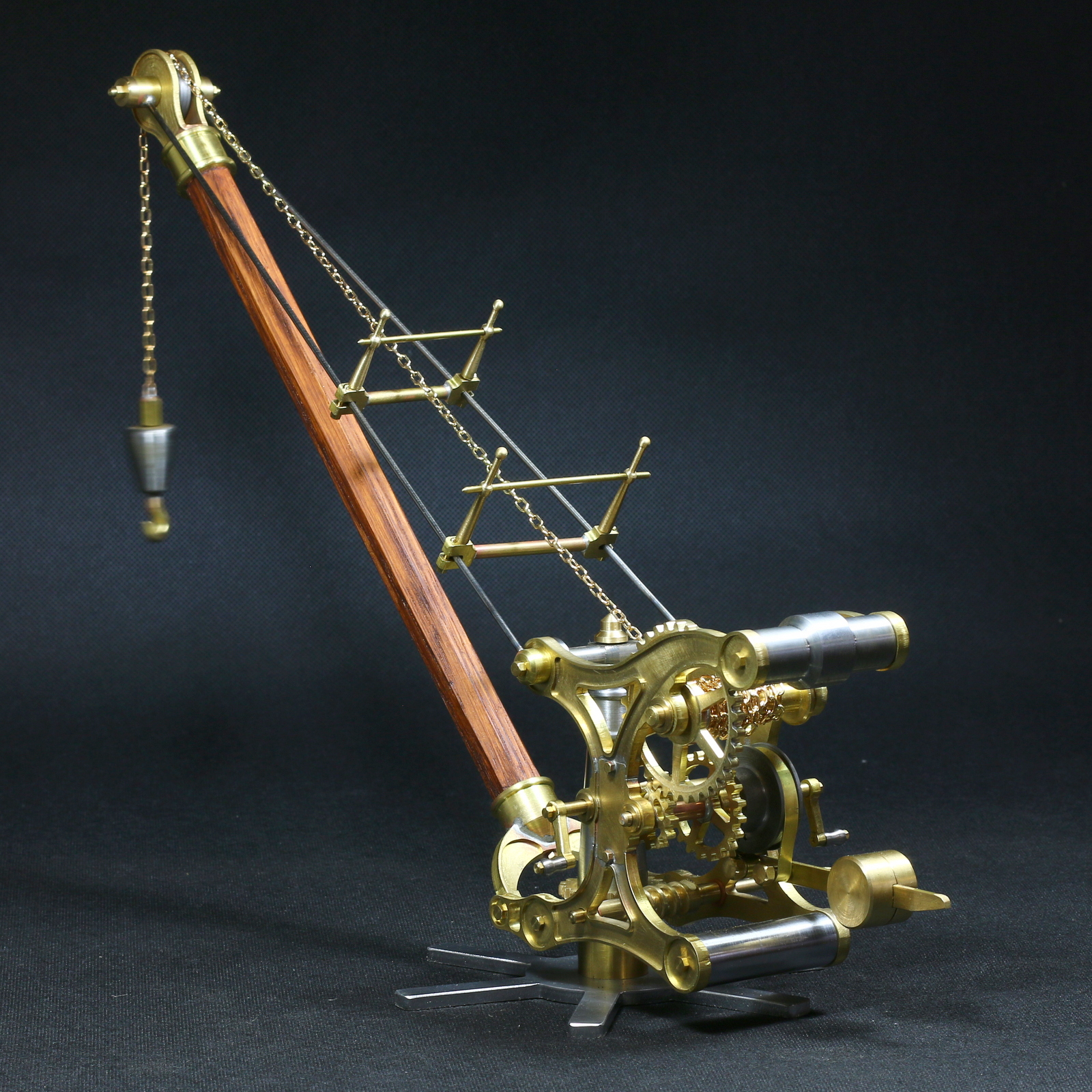

This crane is a replica based on a real harbor crane from England. The model of this crane is located on the edge of a canal in Driffield, East Yorkshire, Great Britain. This crane used to be used to lift goods from ships and even entire boats out of the water. The original and model have a gear with which the chain could be moved either in rapid motion or slowly with a lot of force. The crane has a brake so that the chain spindle does not unroll itself when a load is hanging on the hook. The brake has an integrated freewheel so that the braking force only works in one direction of rotation. When you crank a load up you don't have to overcome the braking force. The crane is rotated via a second spindle with a worm wheel.

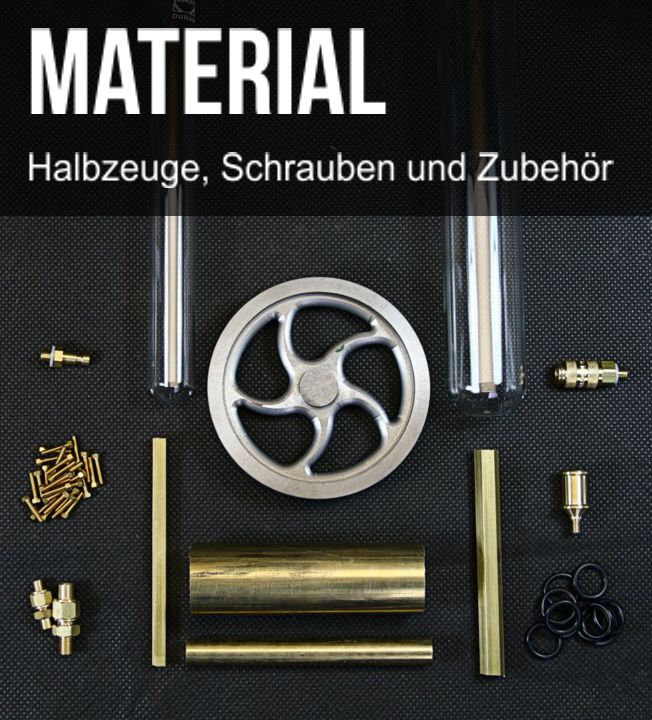

All milled parts in the model are made of brass. The intermediate columns and the rotating columns are supplied as free-cutting steel. The brake drum and idler pulley are made of gray cast iron. A round rod made of oak is included for the boom. The model is fully functional when assembled and can lift and hold loads of up to 250 g. If the base of the crane were to be enlarged even larger loads would not be a problem. The scale of the harbor crane is approximately 1:20.

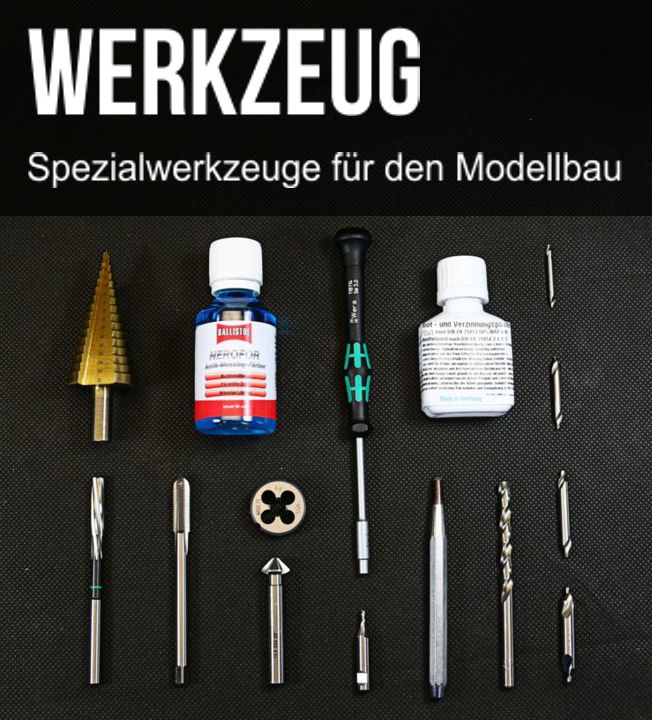

All milled parts are included in the kit ready-made. All turned parts are included in the delivery as raw material. Of course, as with all other Bengs model building material kits, you will also receive all the necessary screws, nuts and a suitable chain. The base made of 4 mm sheet steel is included as a laser-cut sheet metal part. To the construction A small lathe and a column drill are required, as well as a gas burner for soft soldering. The following should also be available: M2, M3, M4 taps, M3 dies, 4H7, 6H7, 8H7 reamers, files and a drill set. Otherwise, hand tools, which should be in every “technical model making workshop”, are necessary.

Here you will find a comprehensive construction report with lots of pictures for the Hercules harbor crane material kit

Scope of delivery harbor crane material kit

- Finished milled parts

- Raw material for the turned parts

- All required screws, nuts and chain

- Construction plan harbor crane drawings (16 sheets) and construction instructions (4 sheets)

- Laser part base

Dimensions of harbor crane material kit

- Height: 260mm

- Length overall: 350mm

- Max. Lifting weight with standard base: 250g

- Weight: 1.1kg

Login