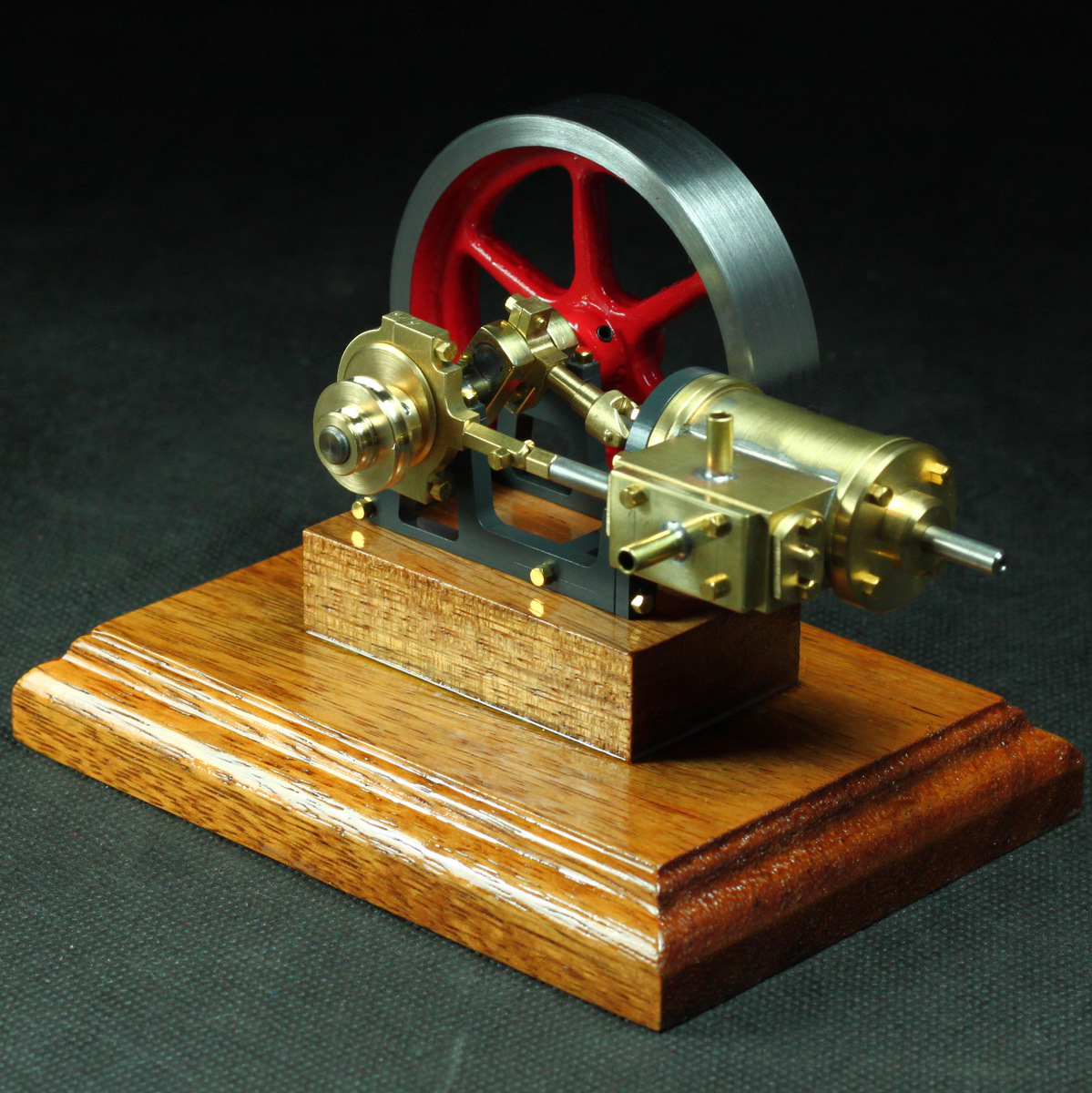

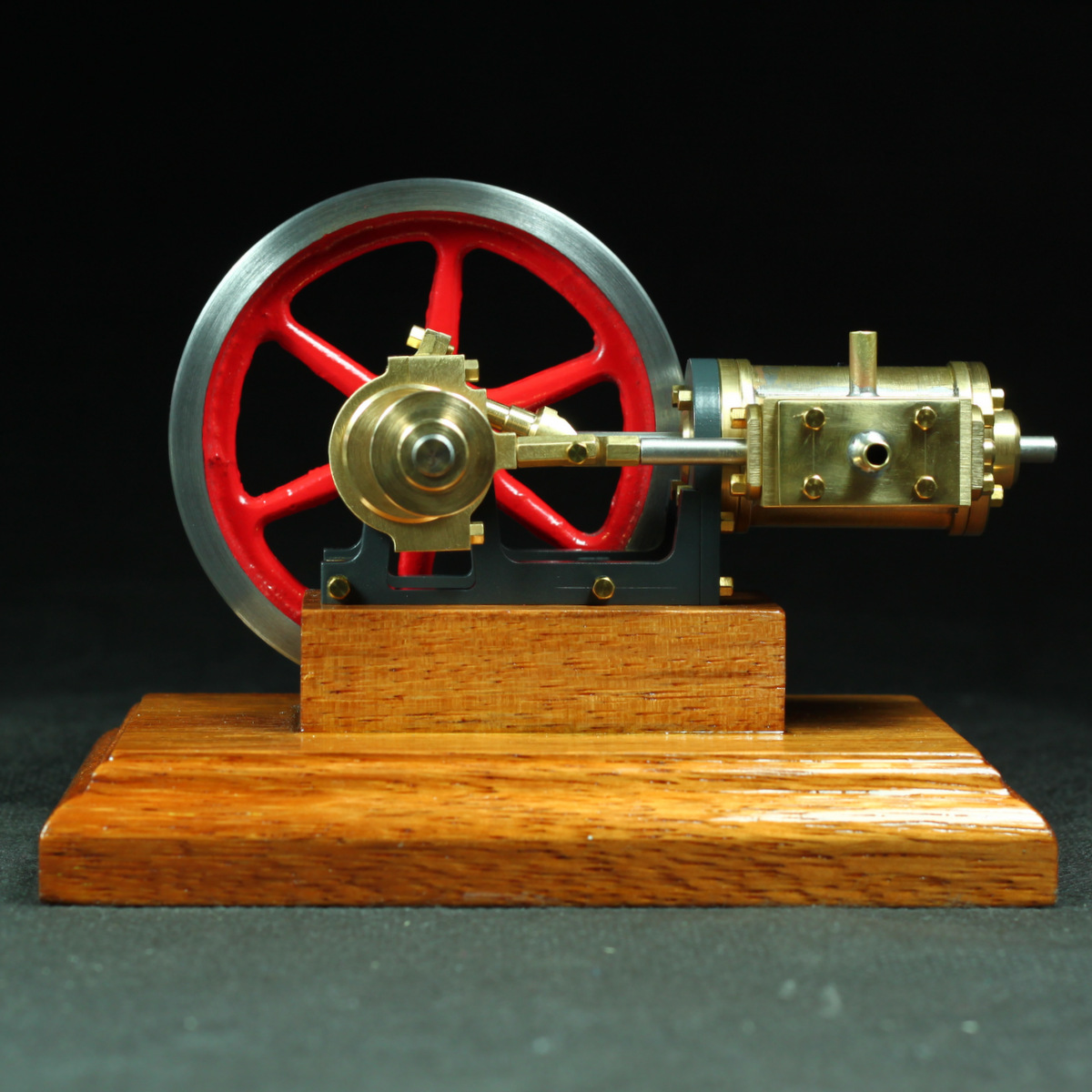

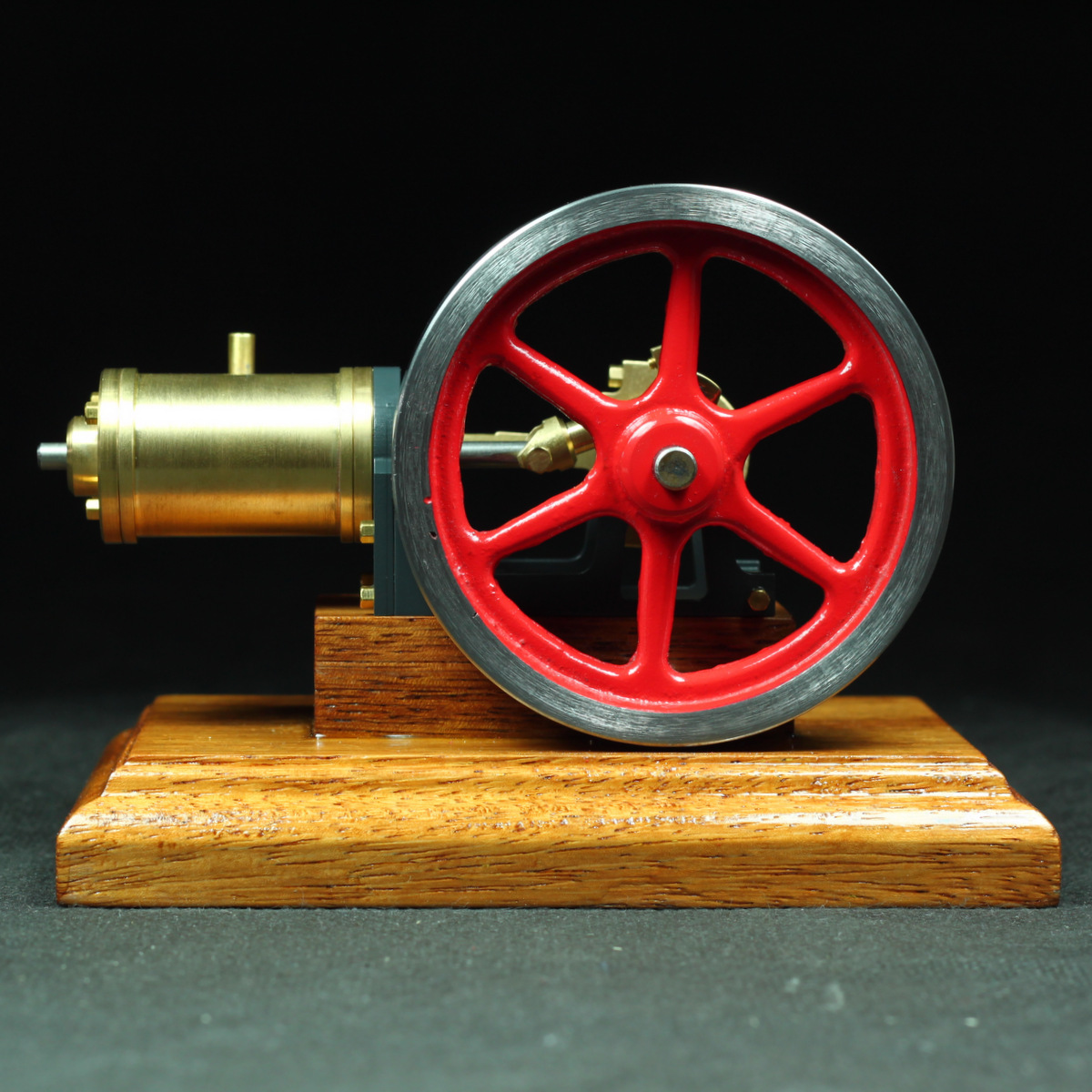

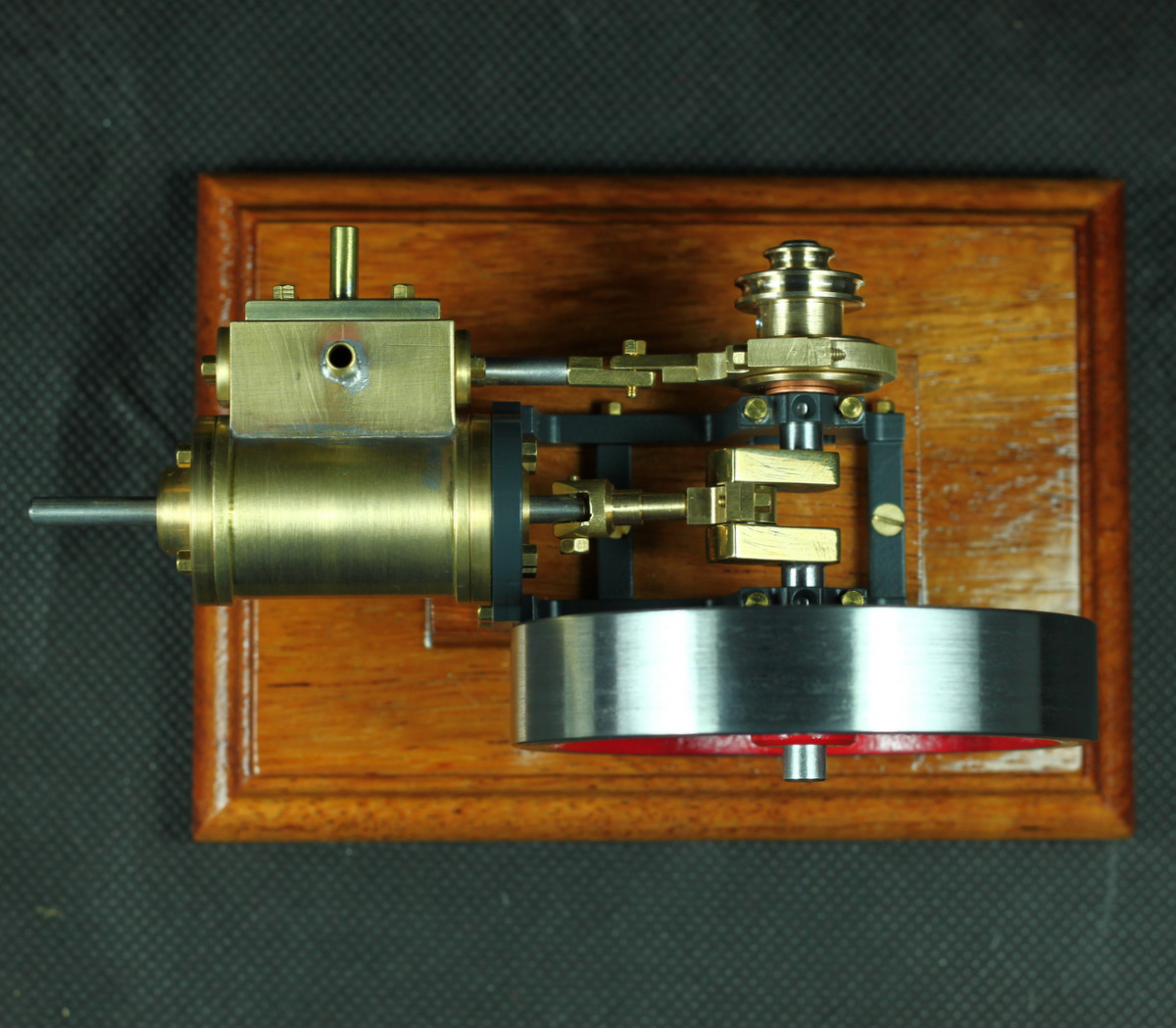

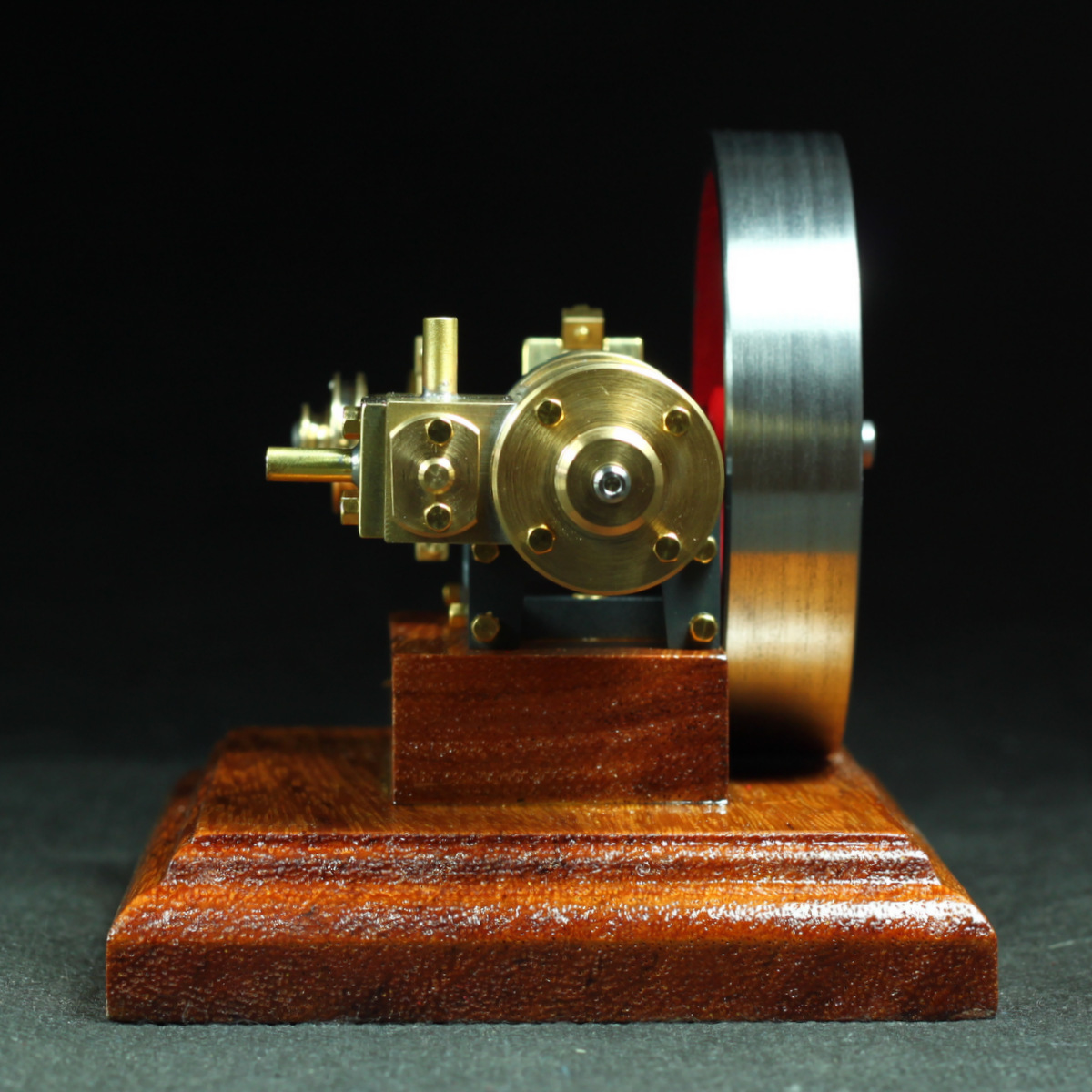

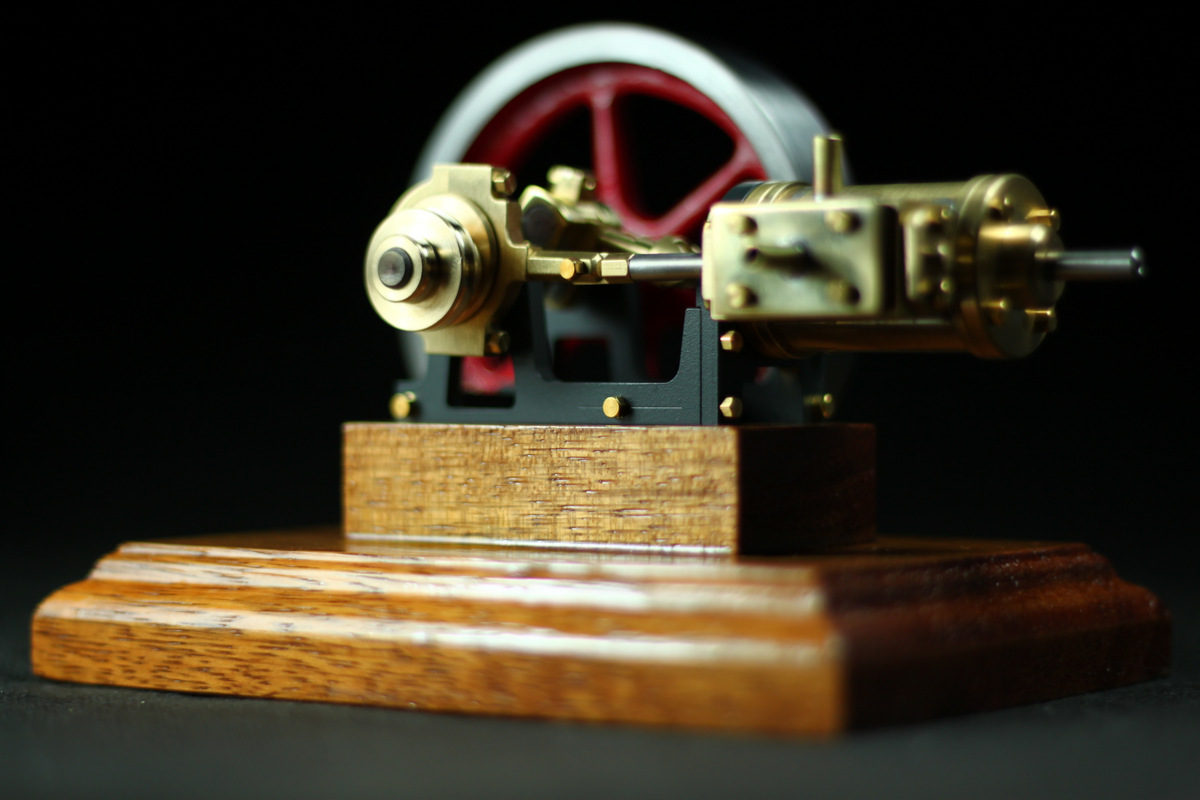

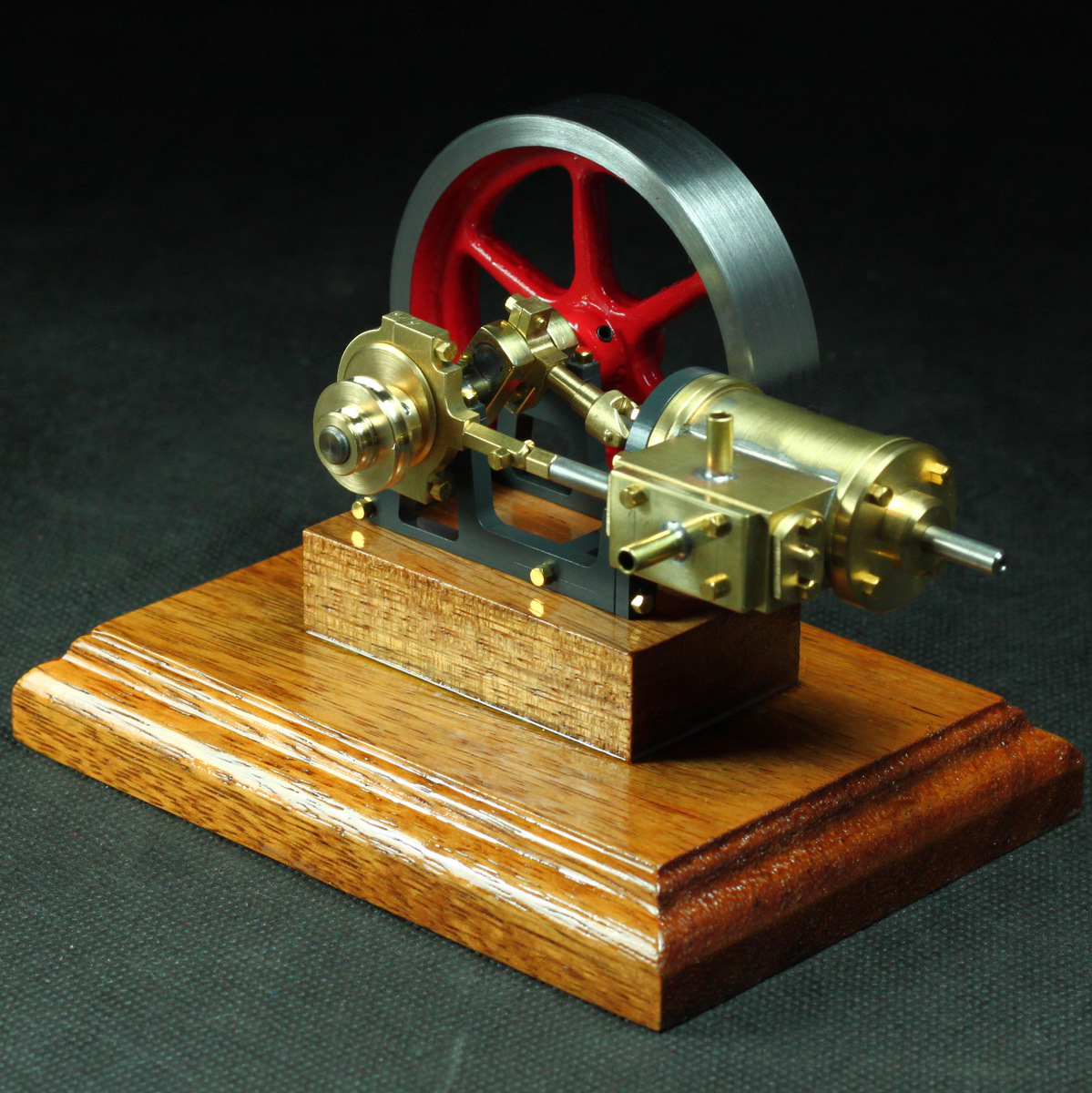

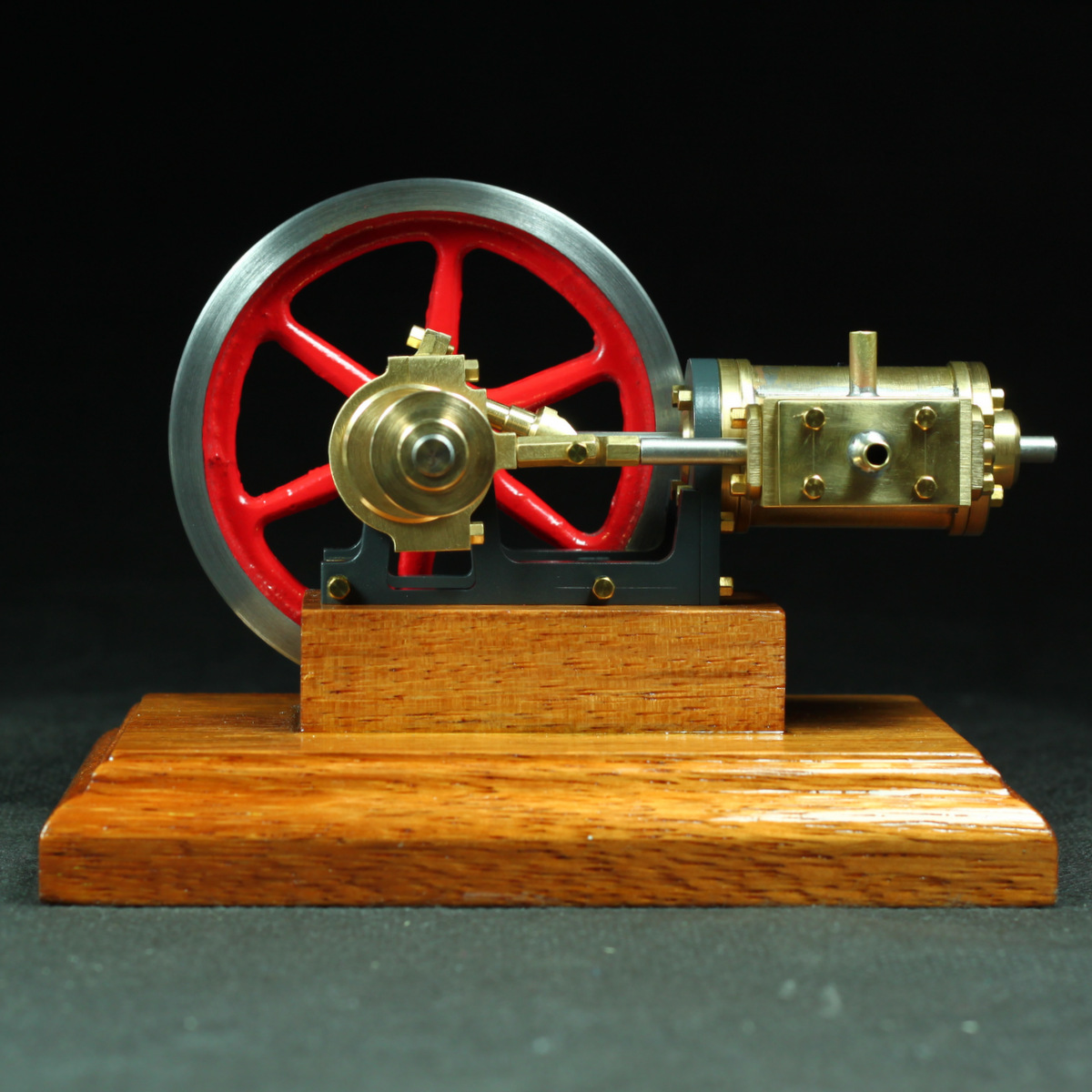

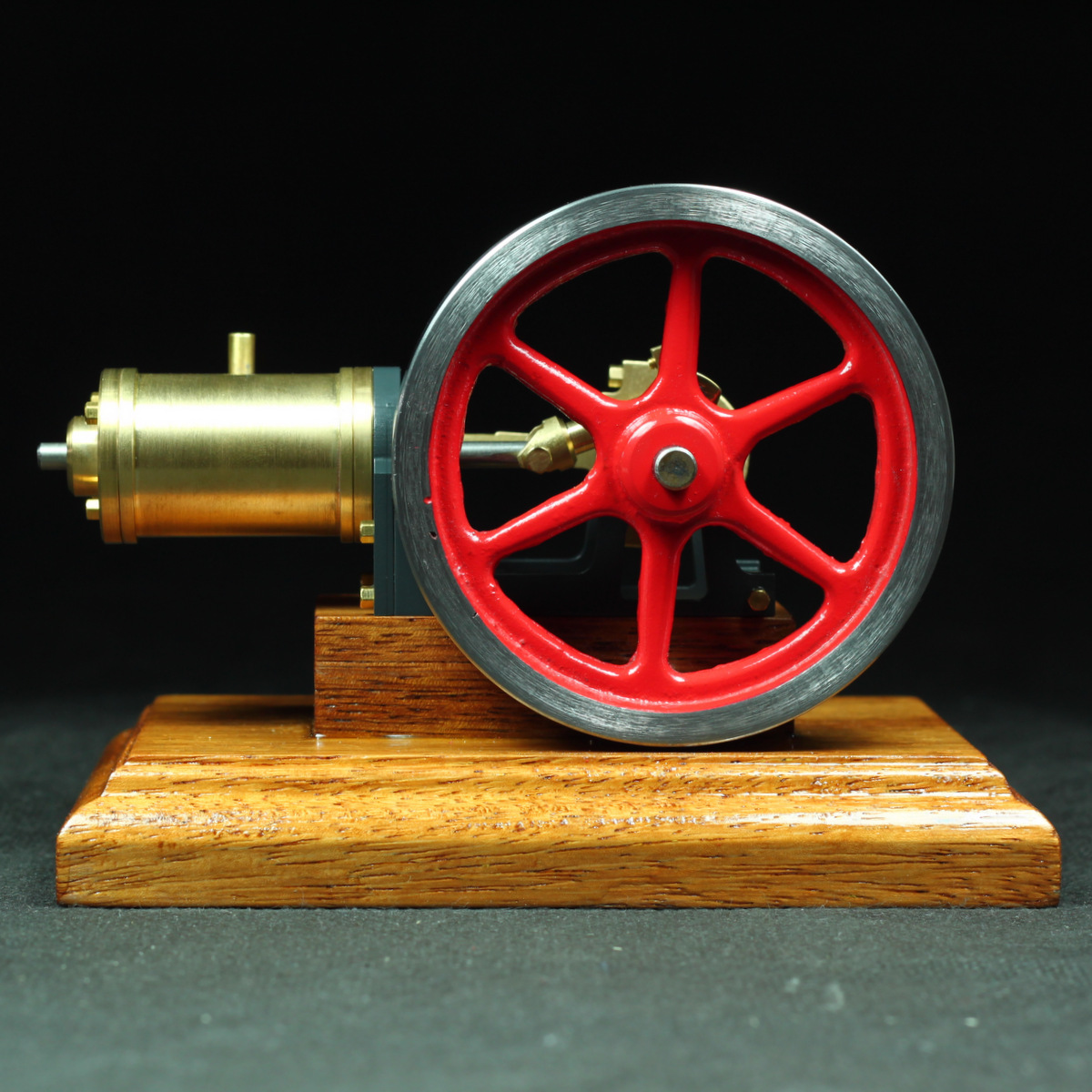

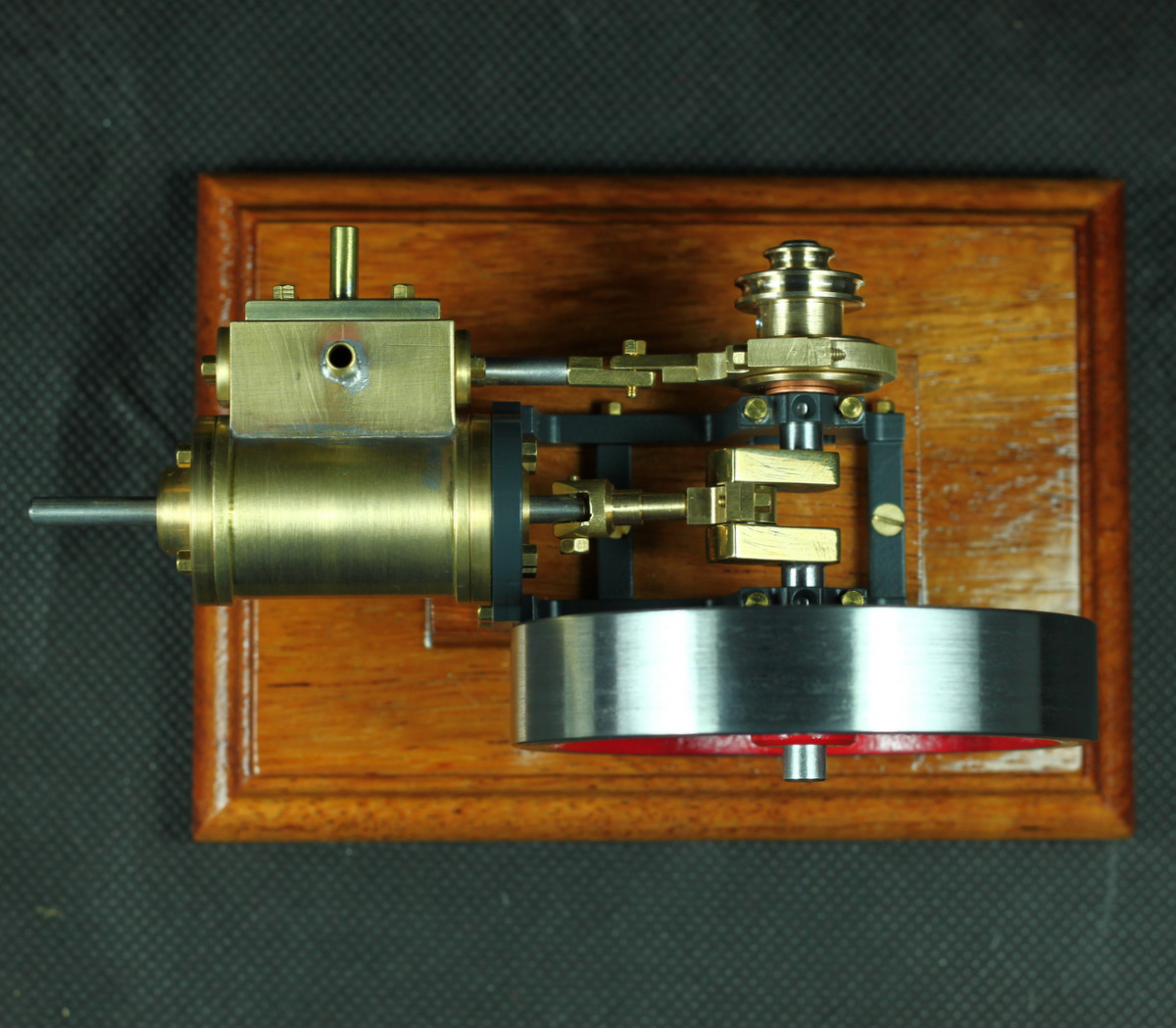

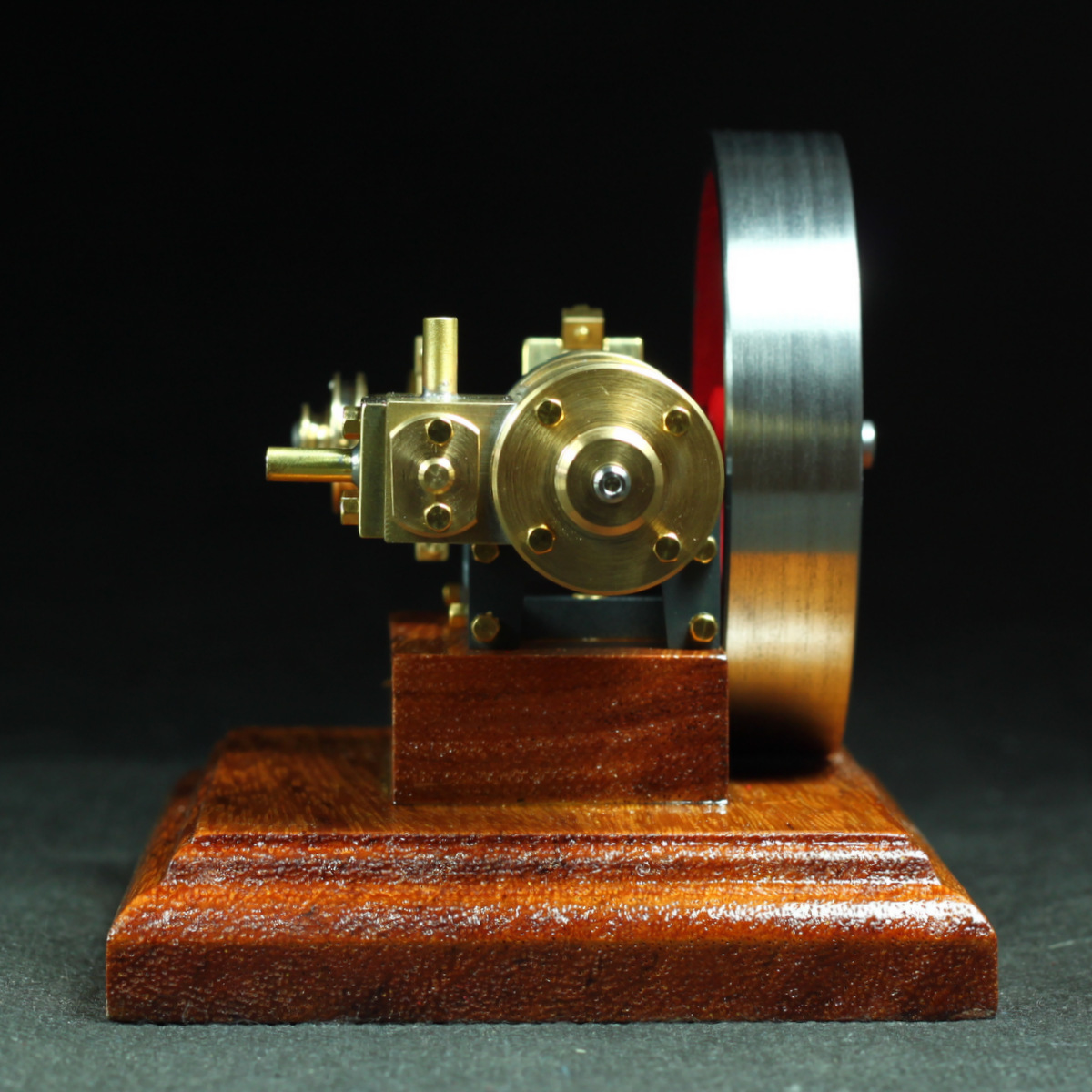

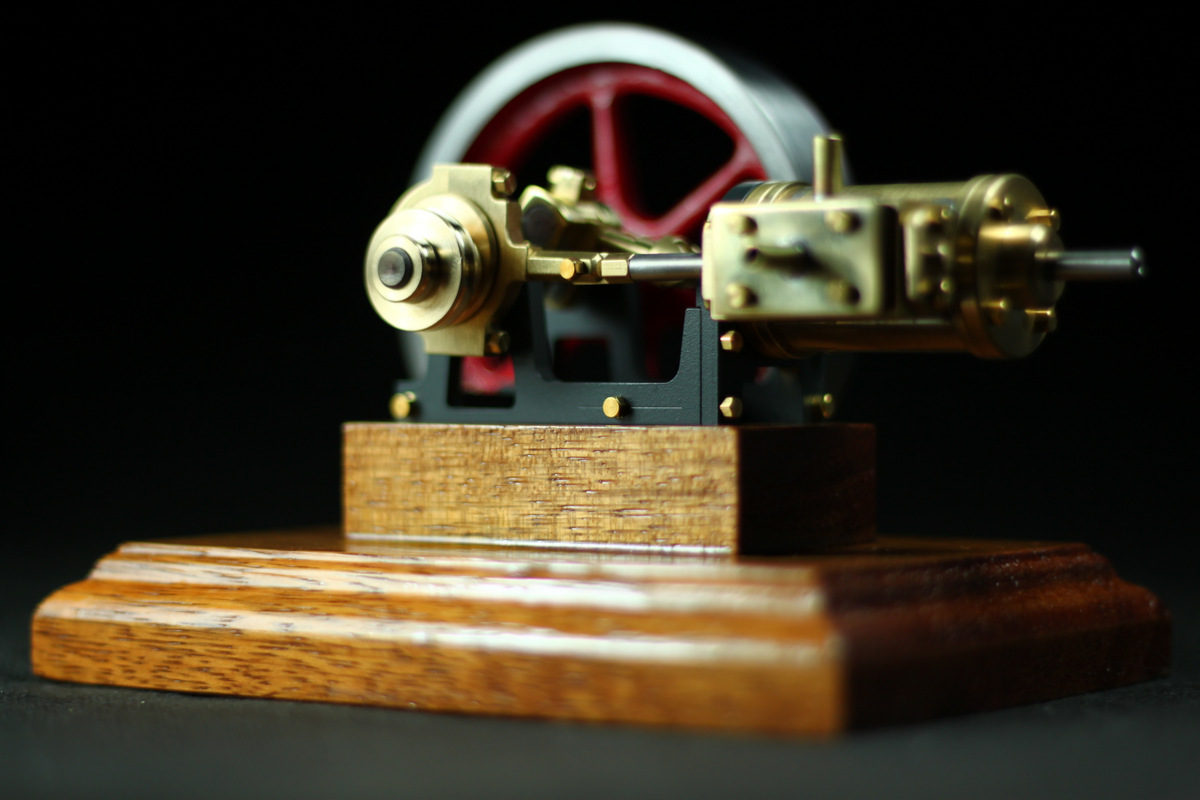

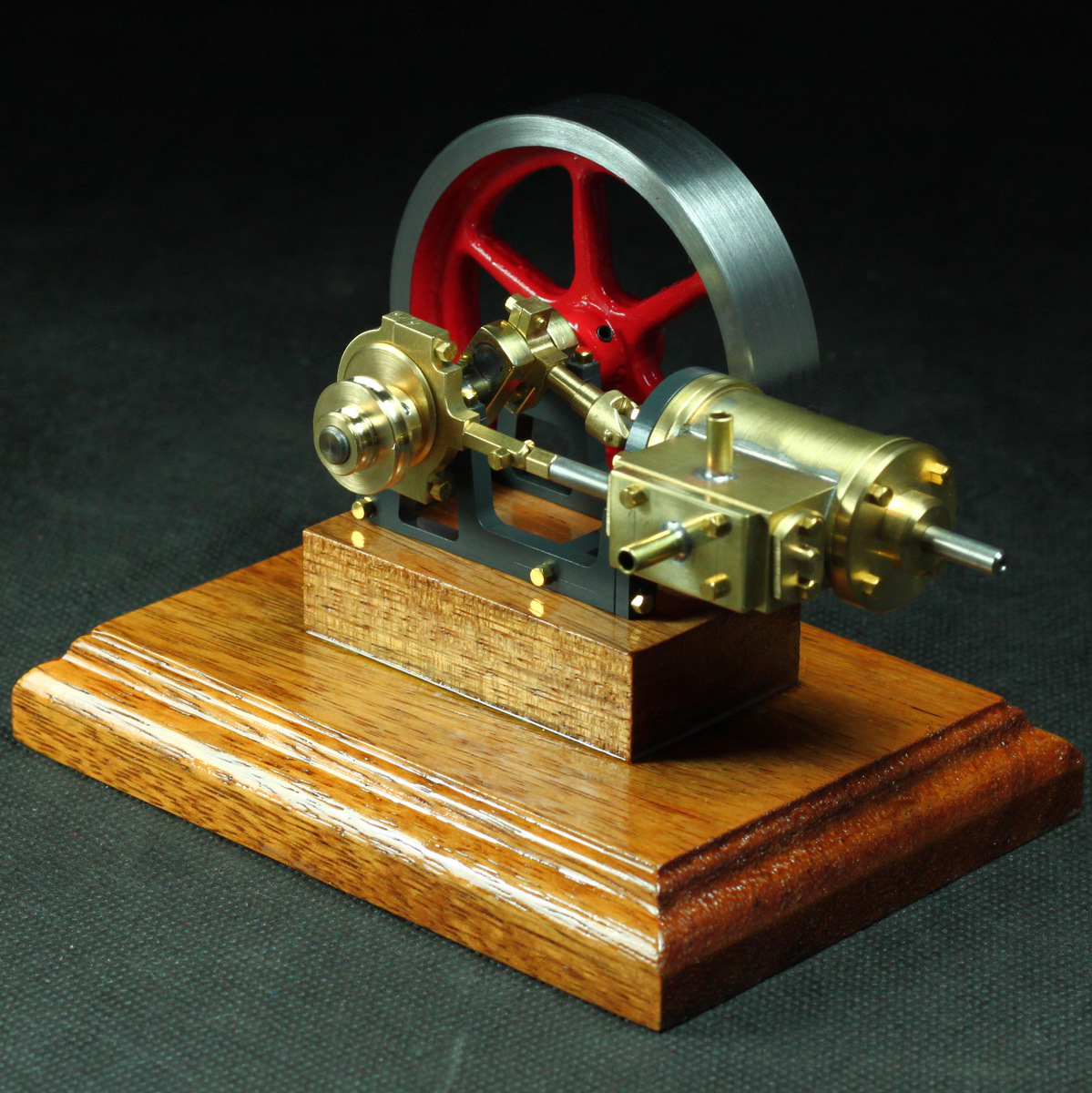

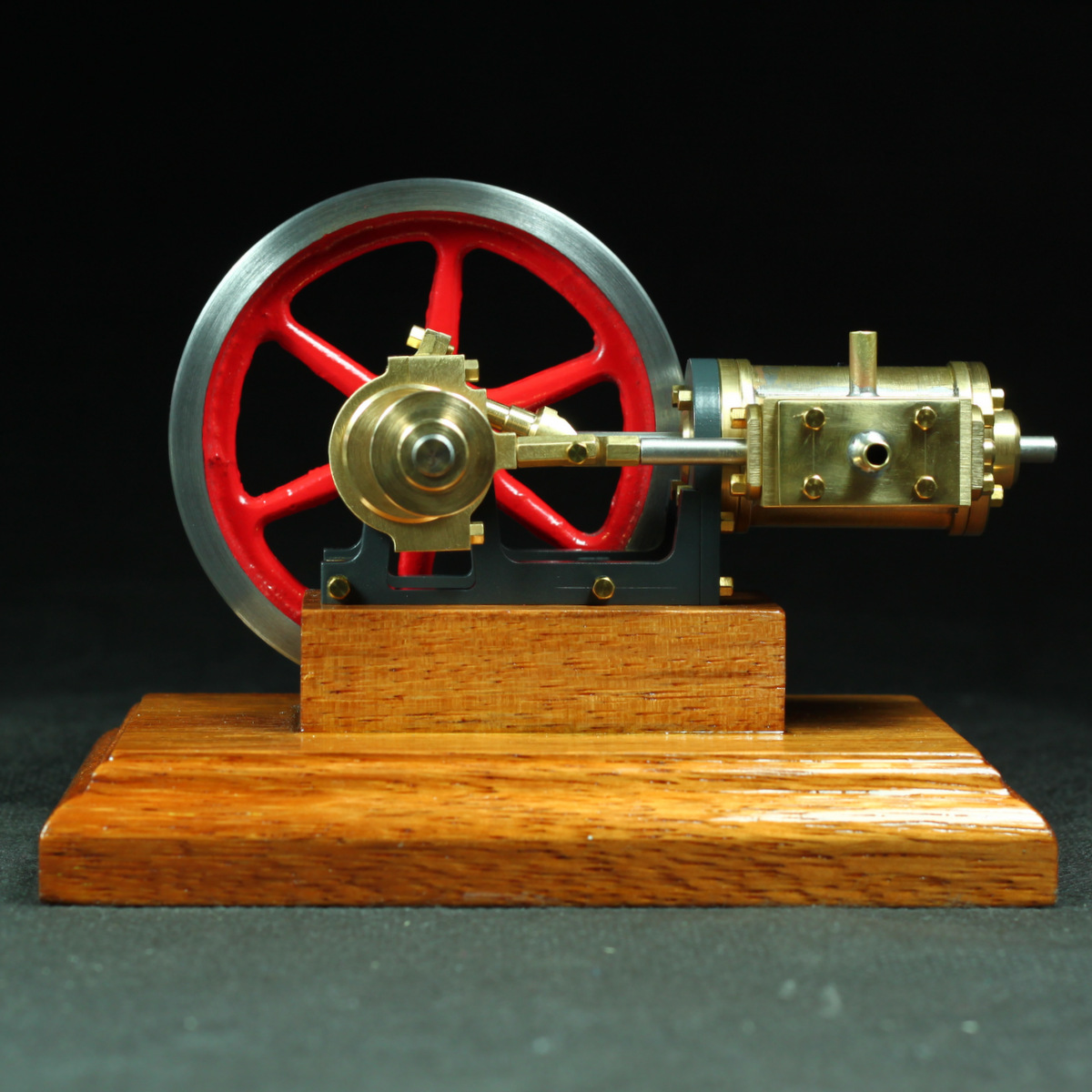

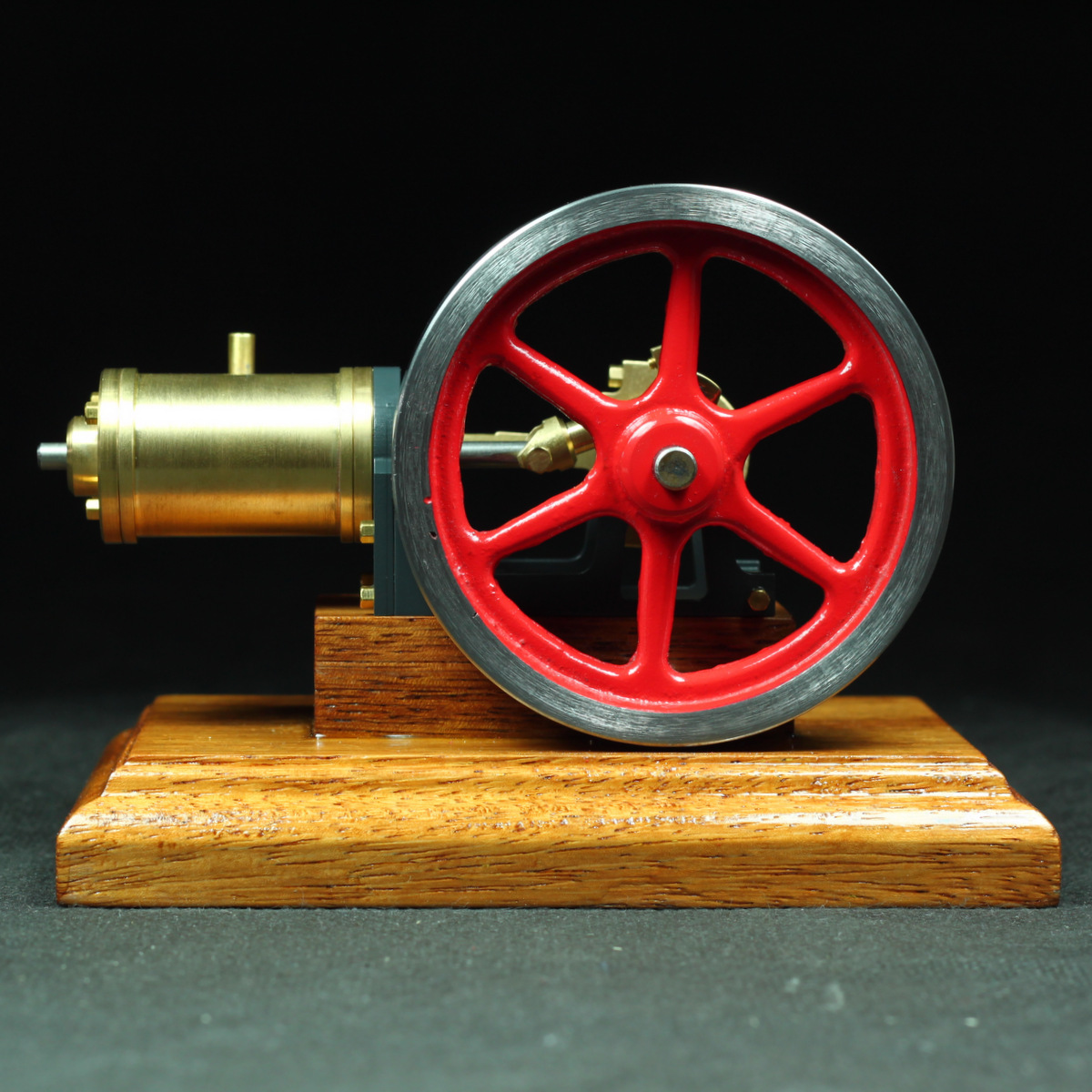

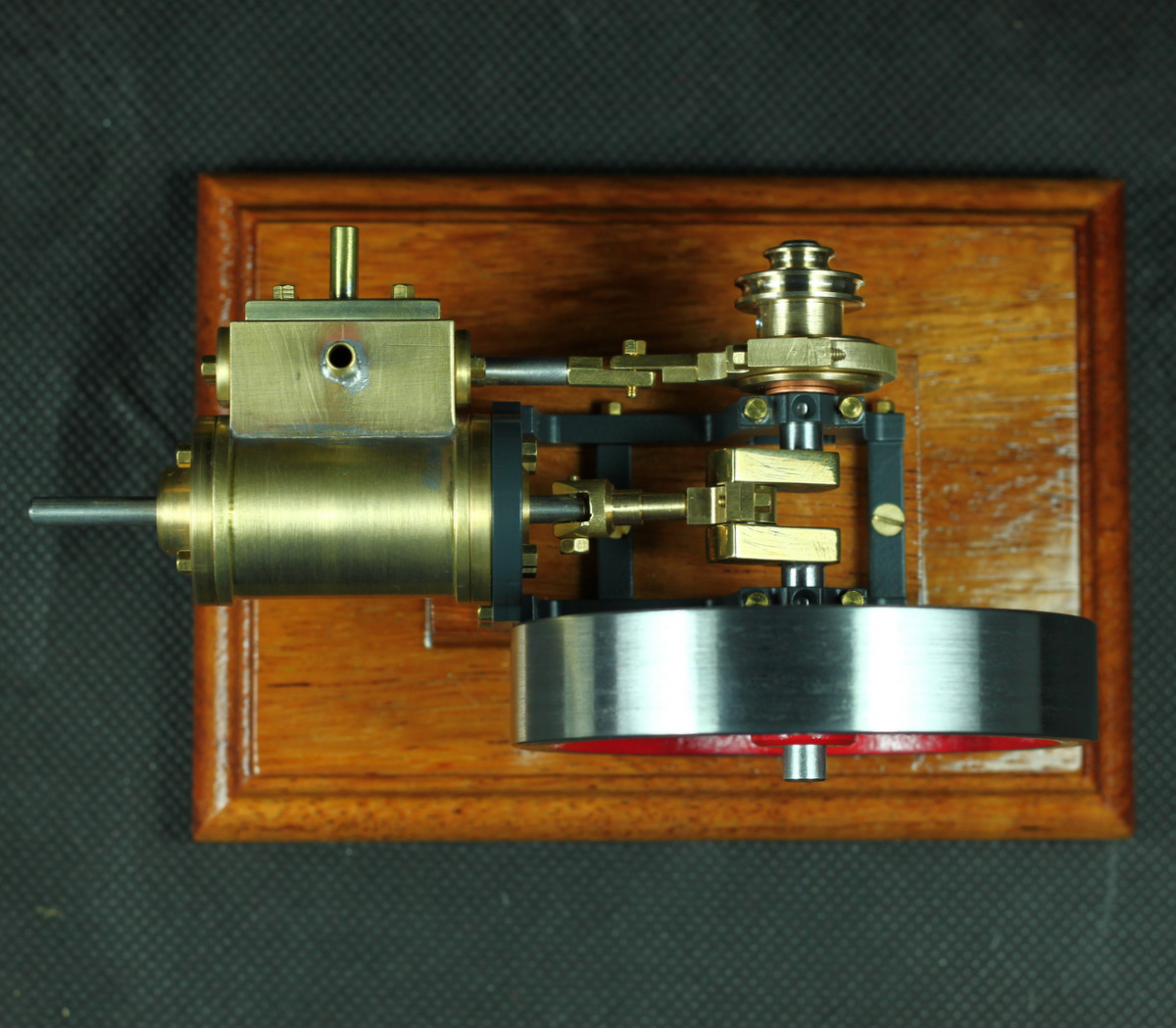

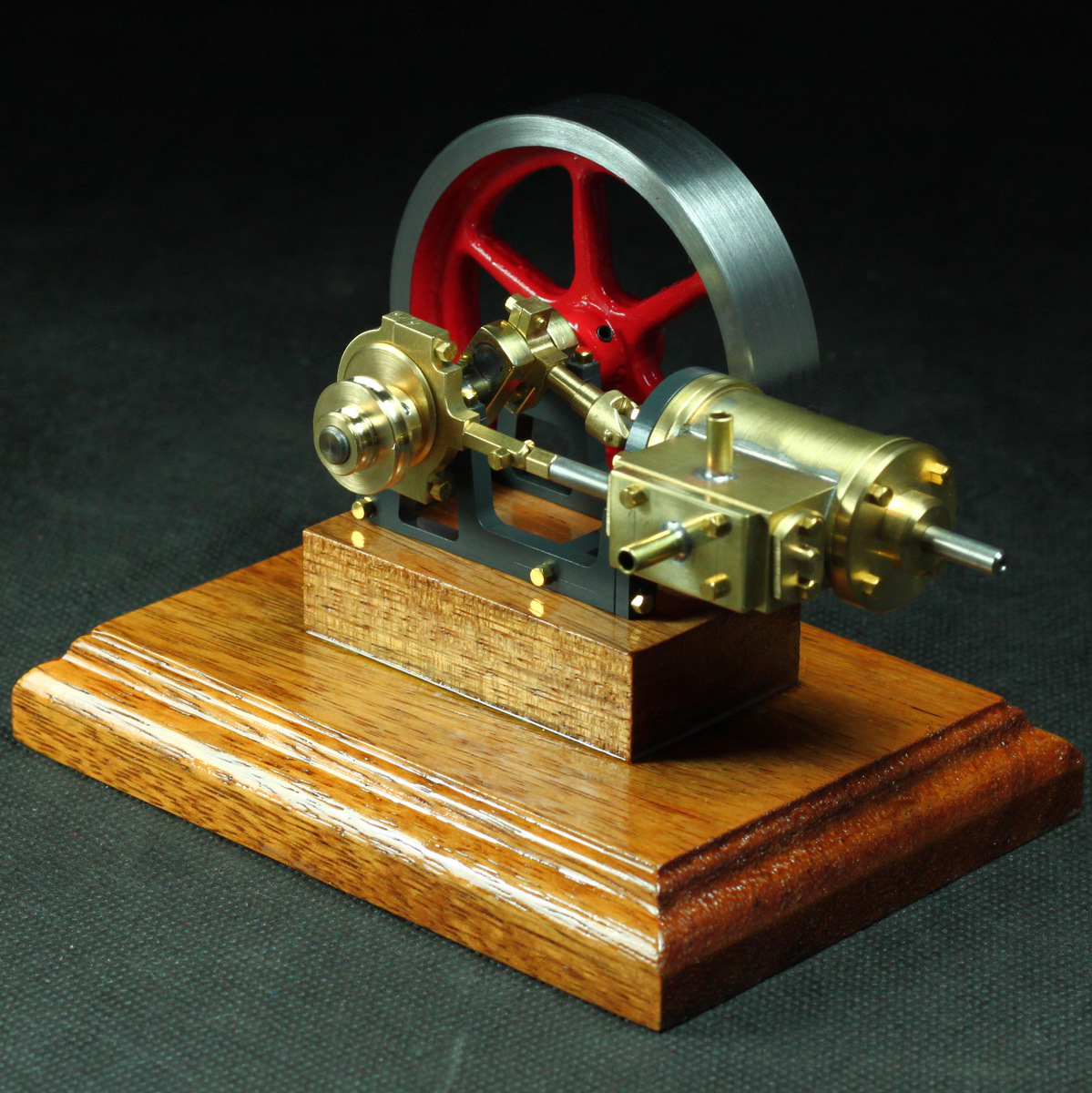

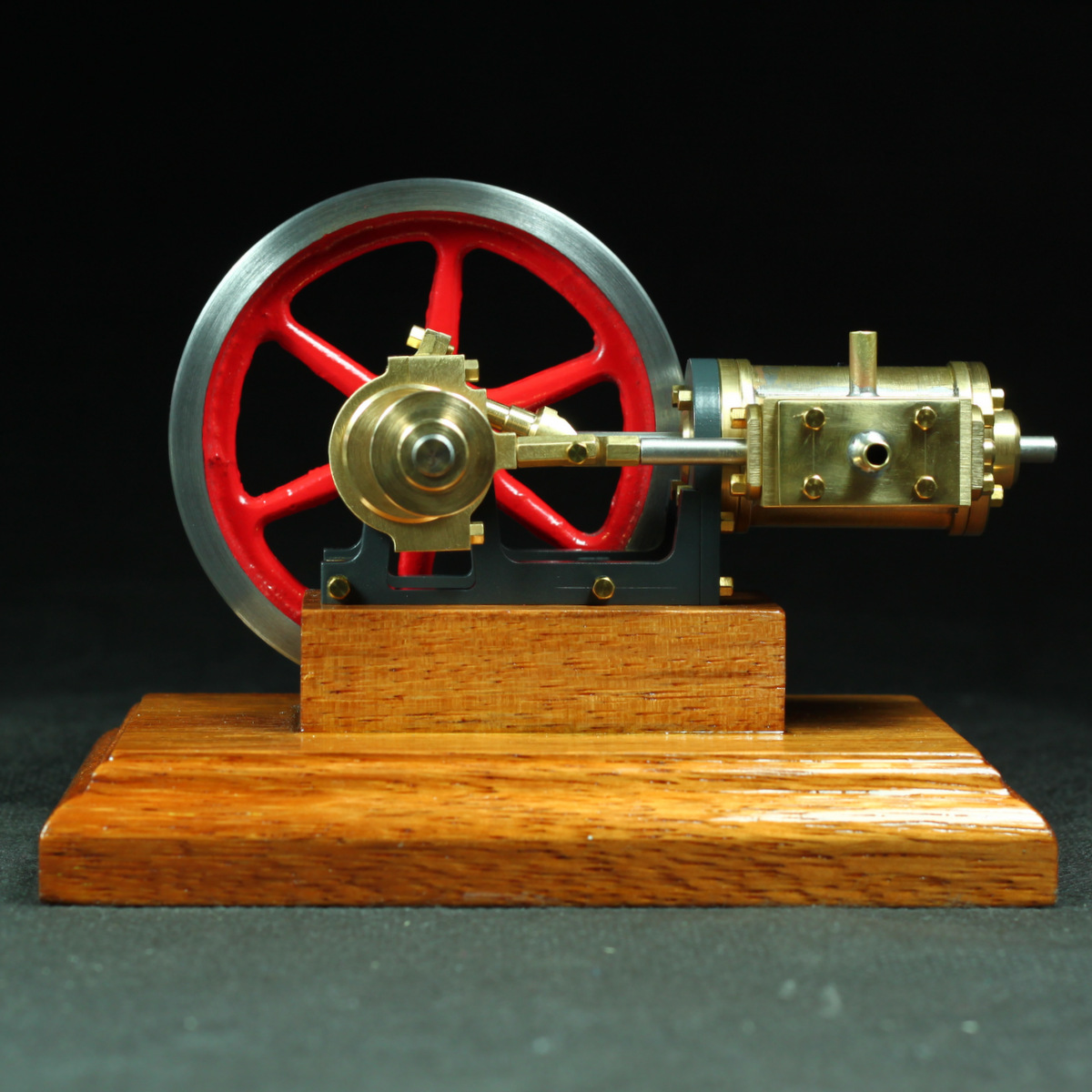

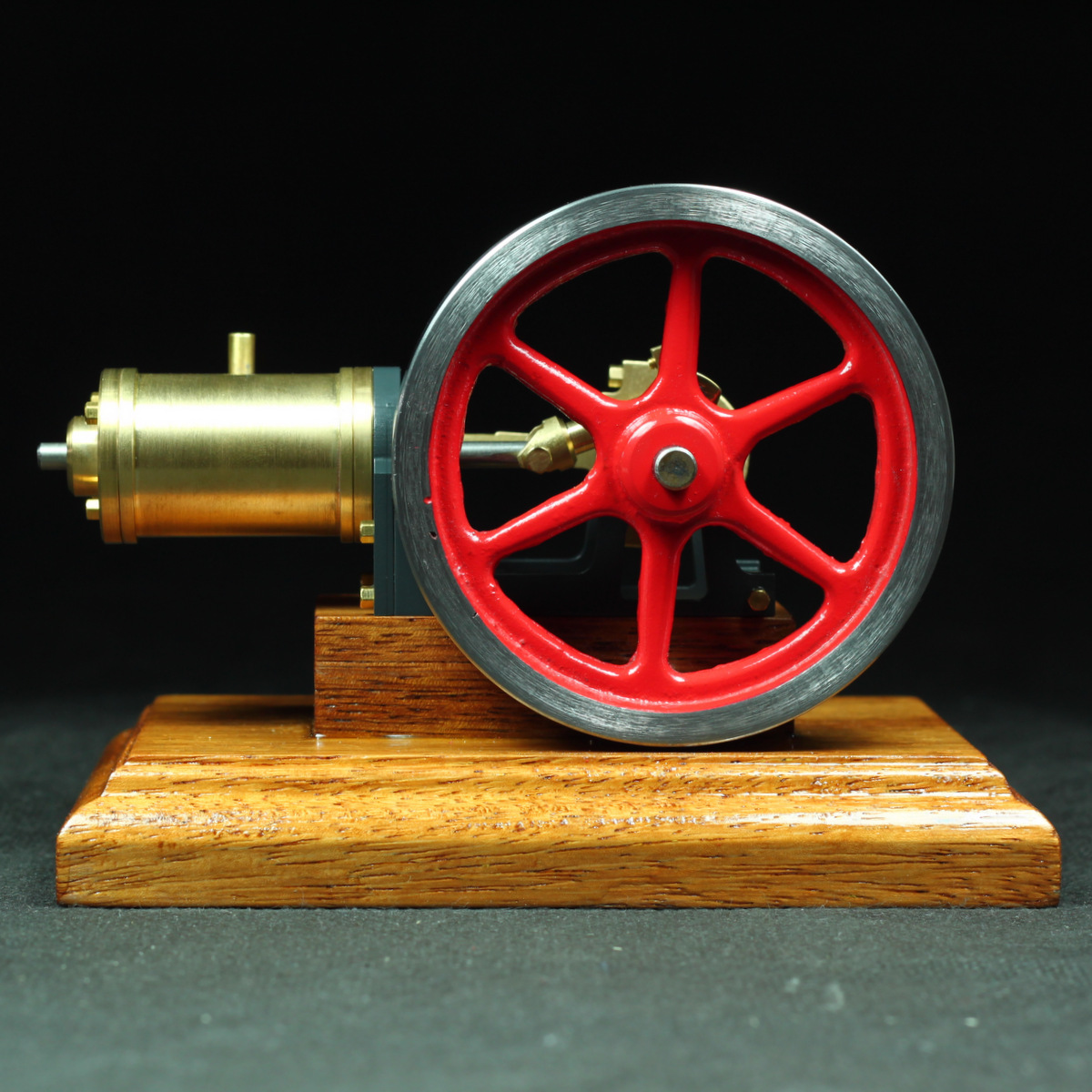

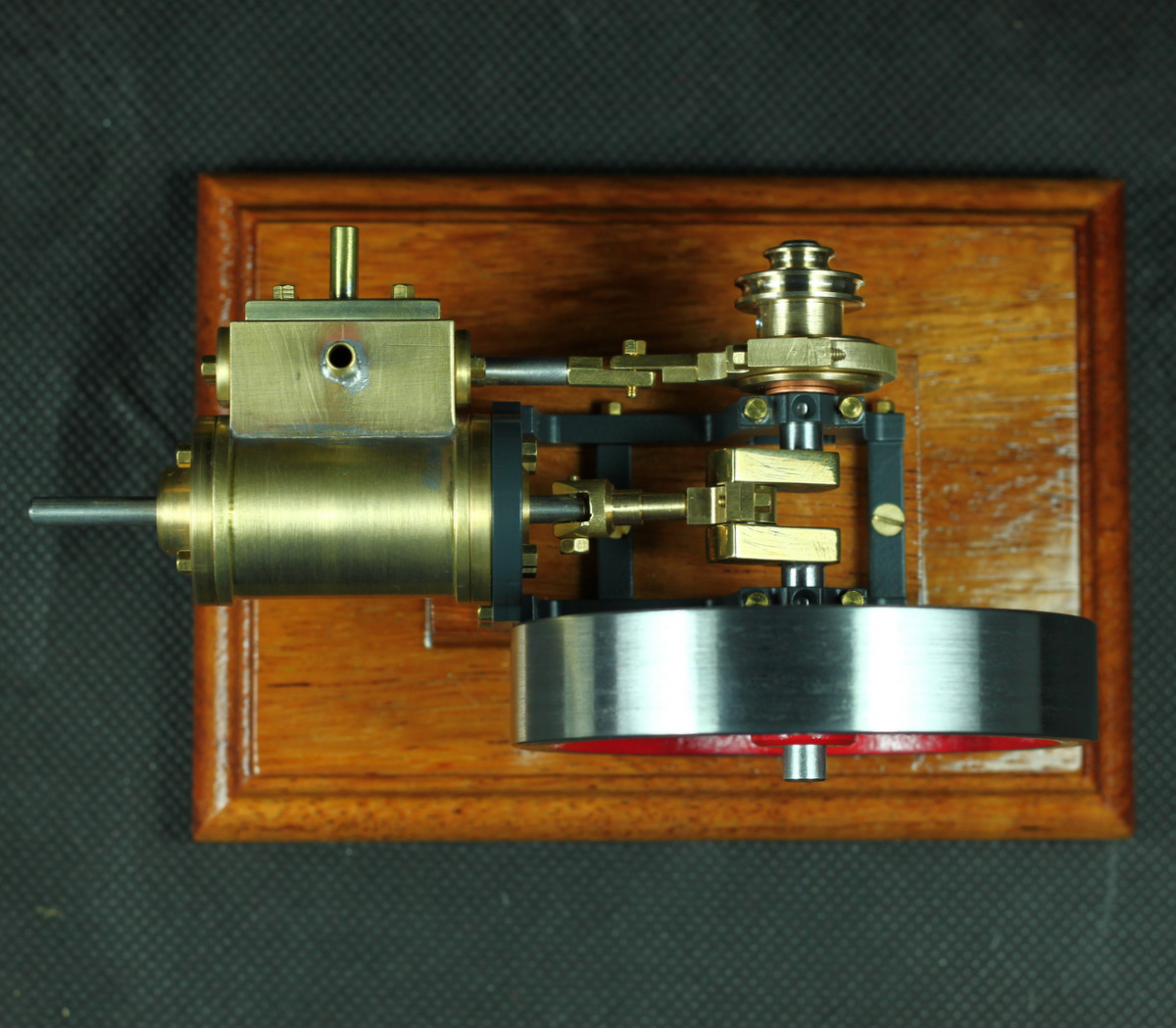

Horizontal steam engine Danni

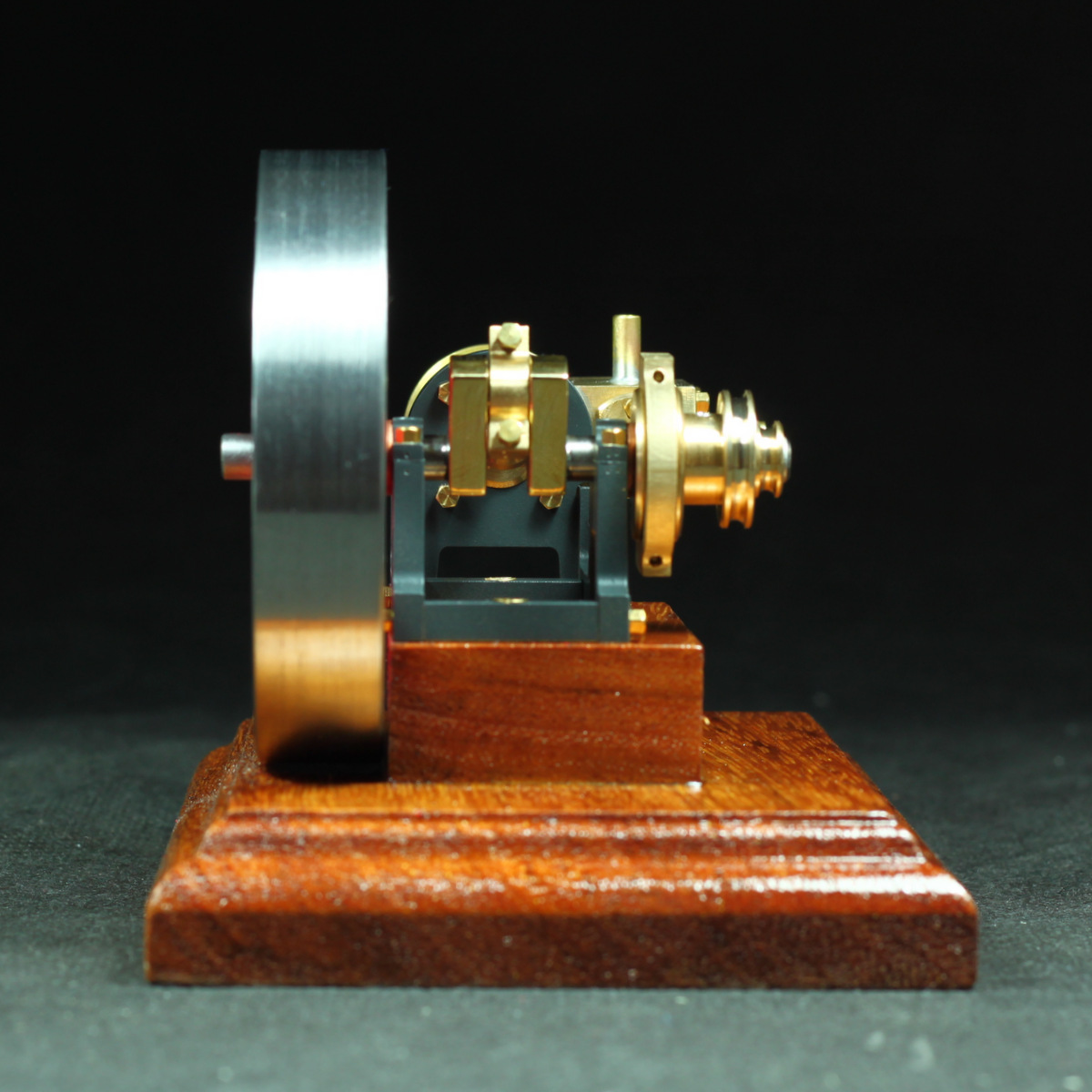

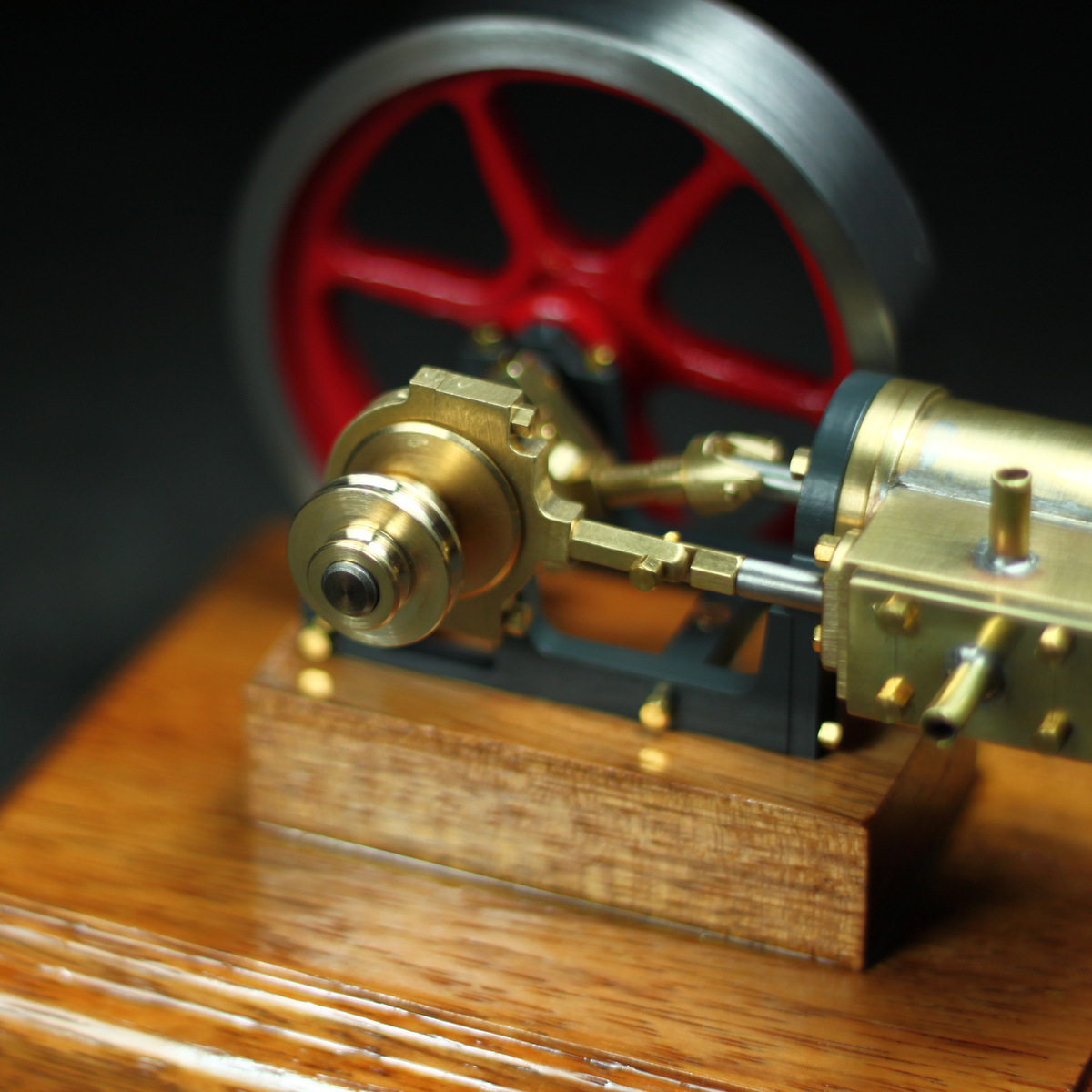

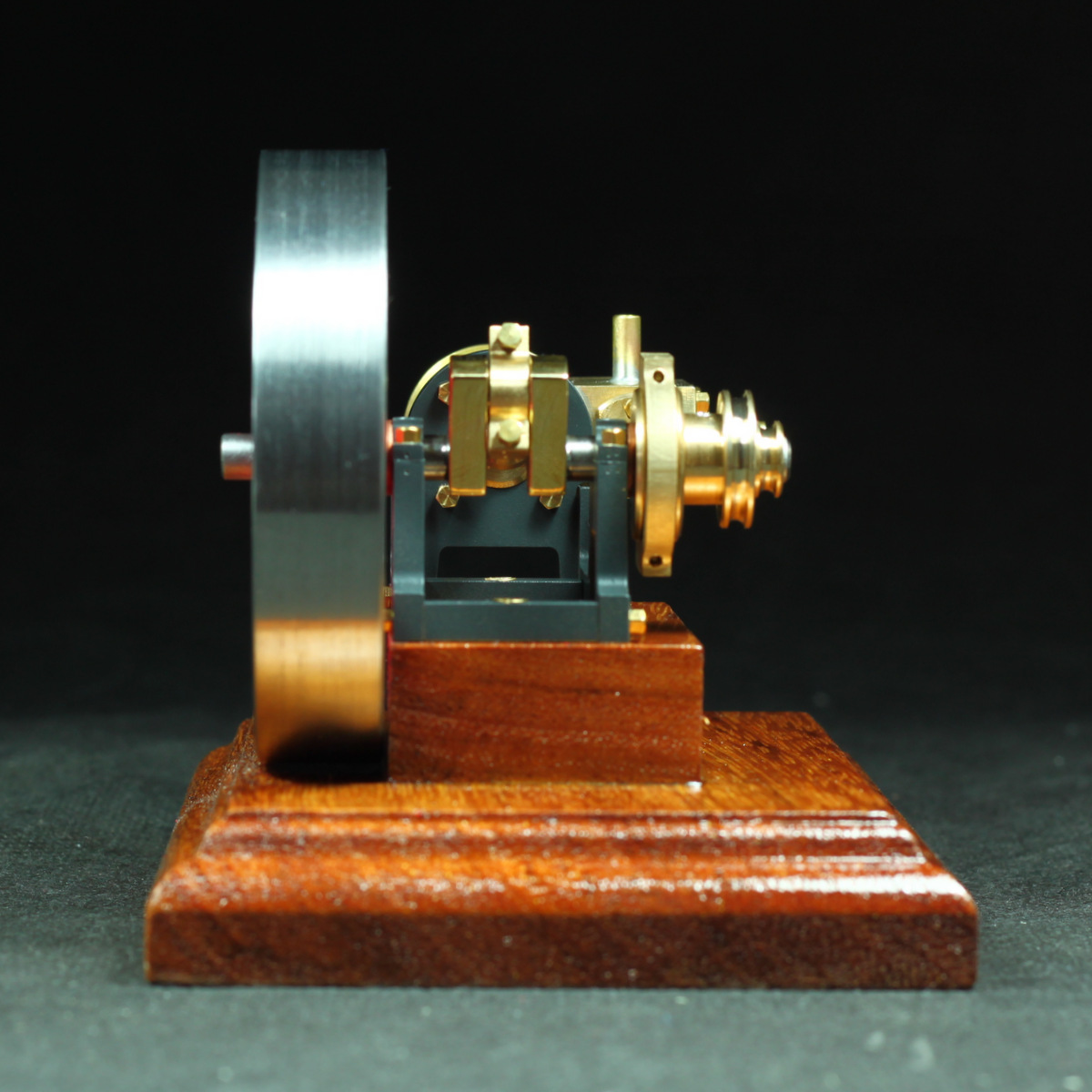

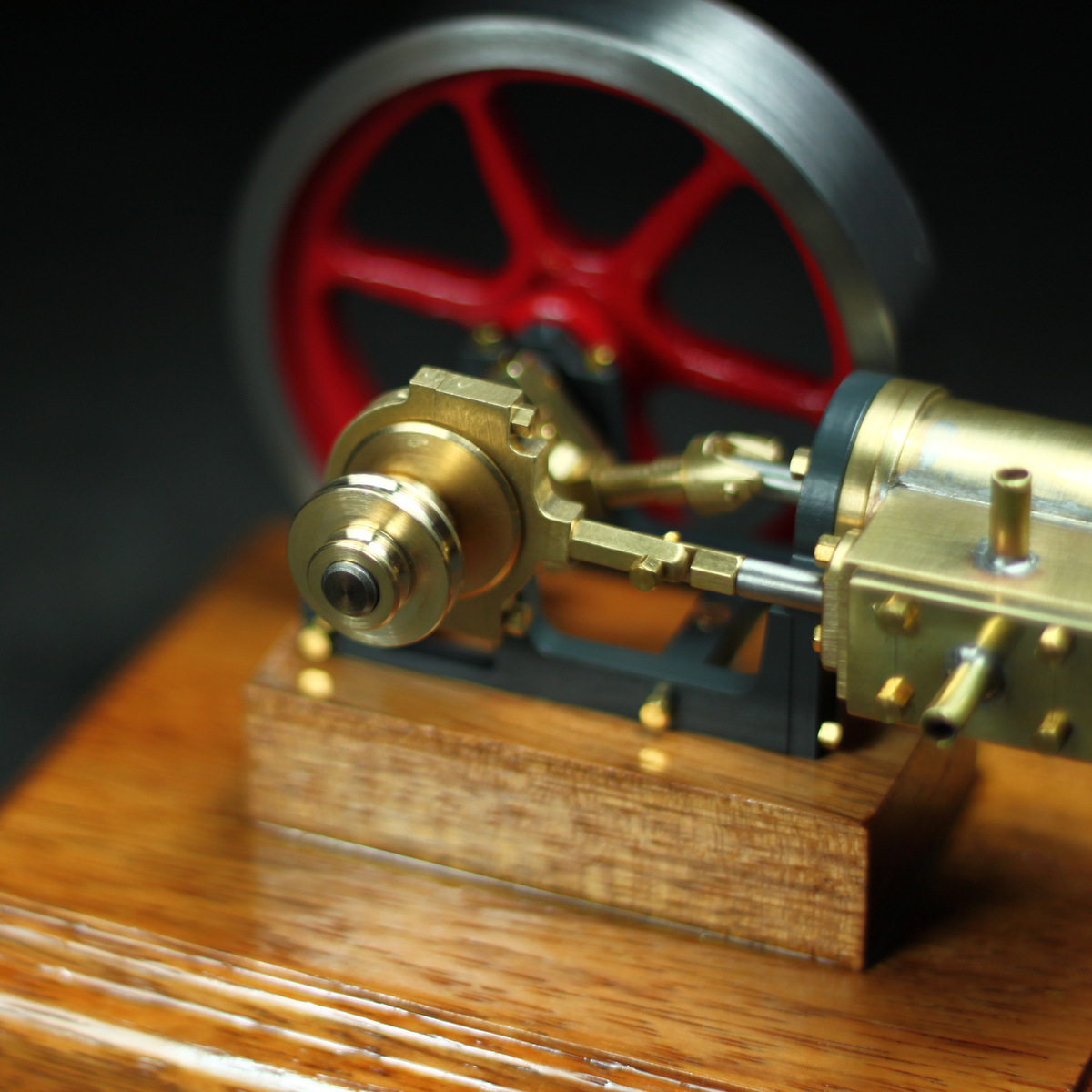

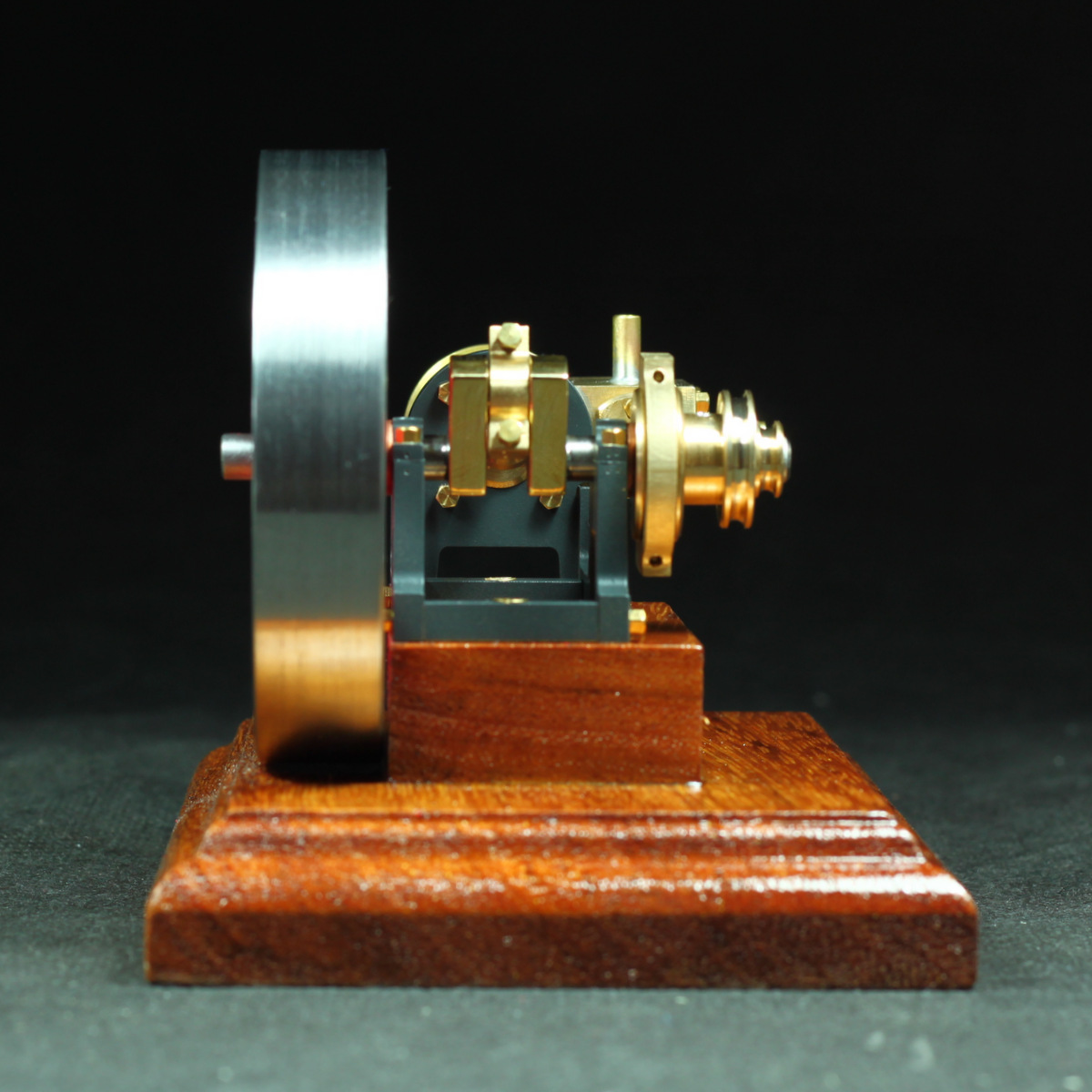

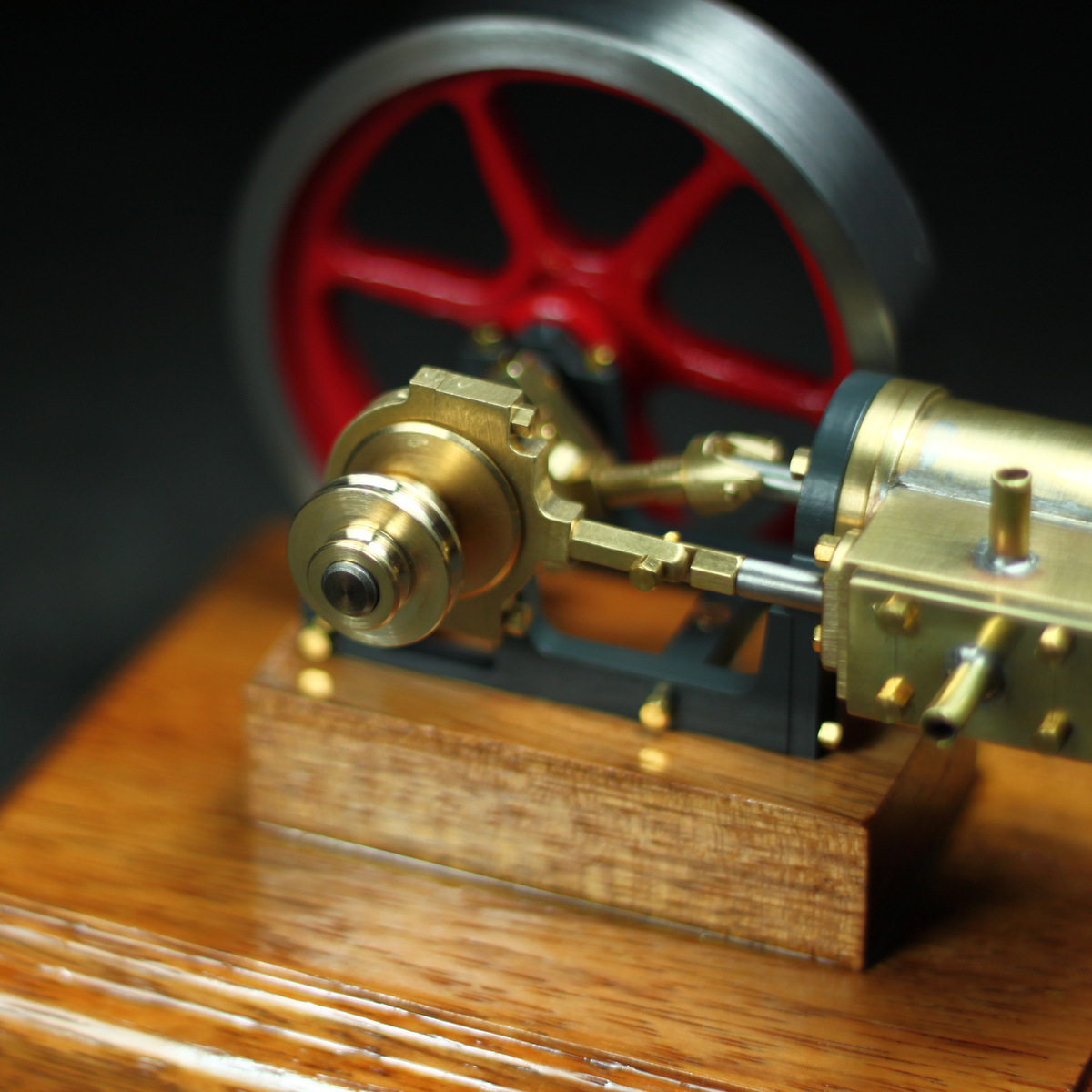

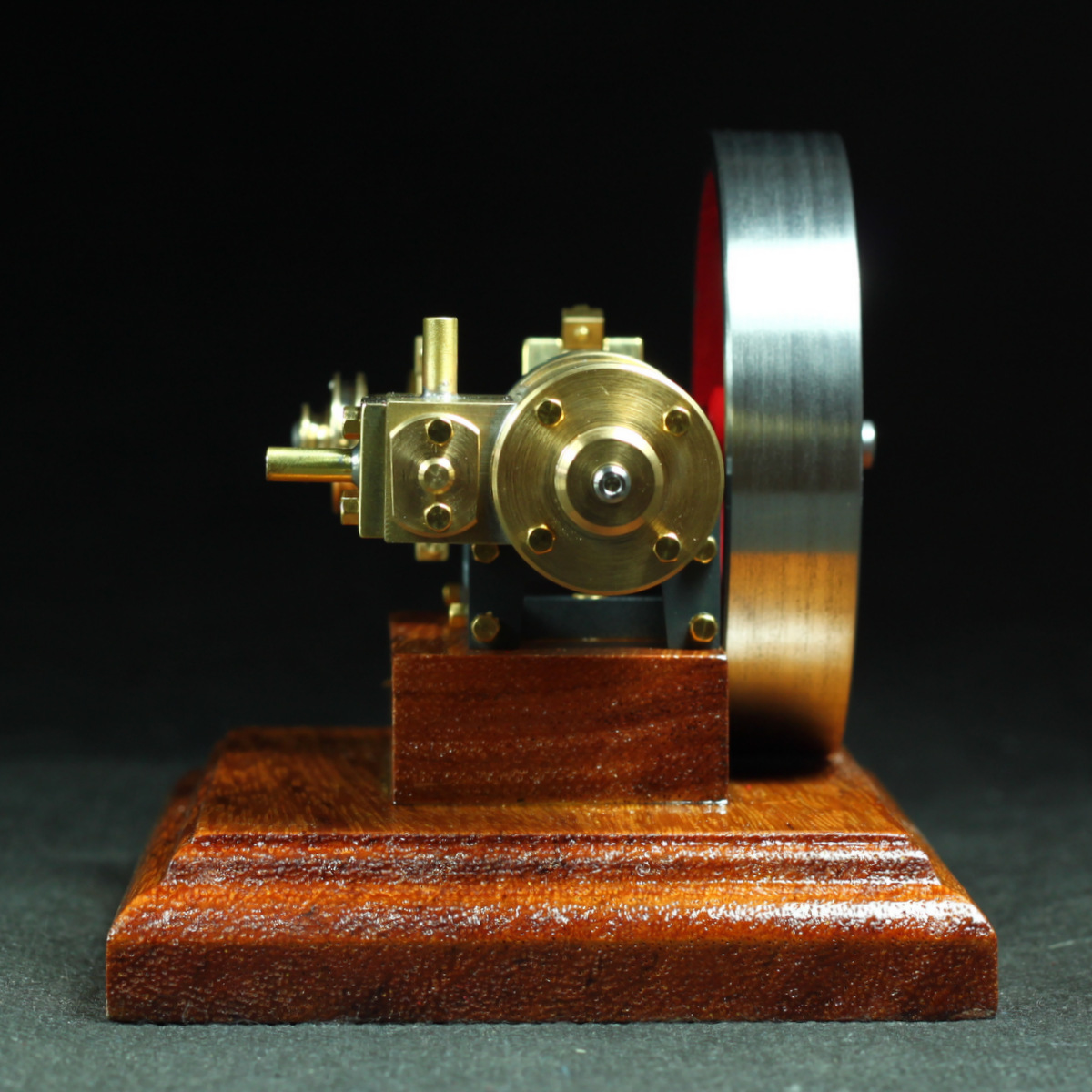

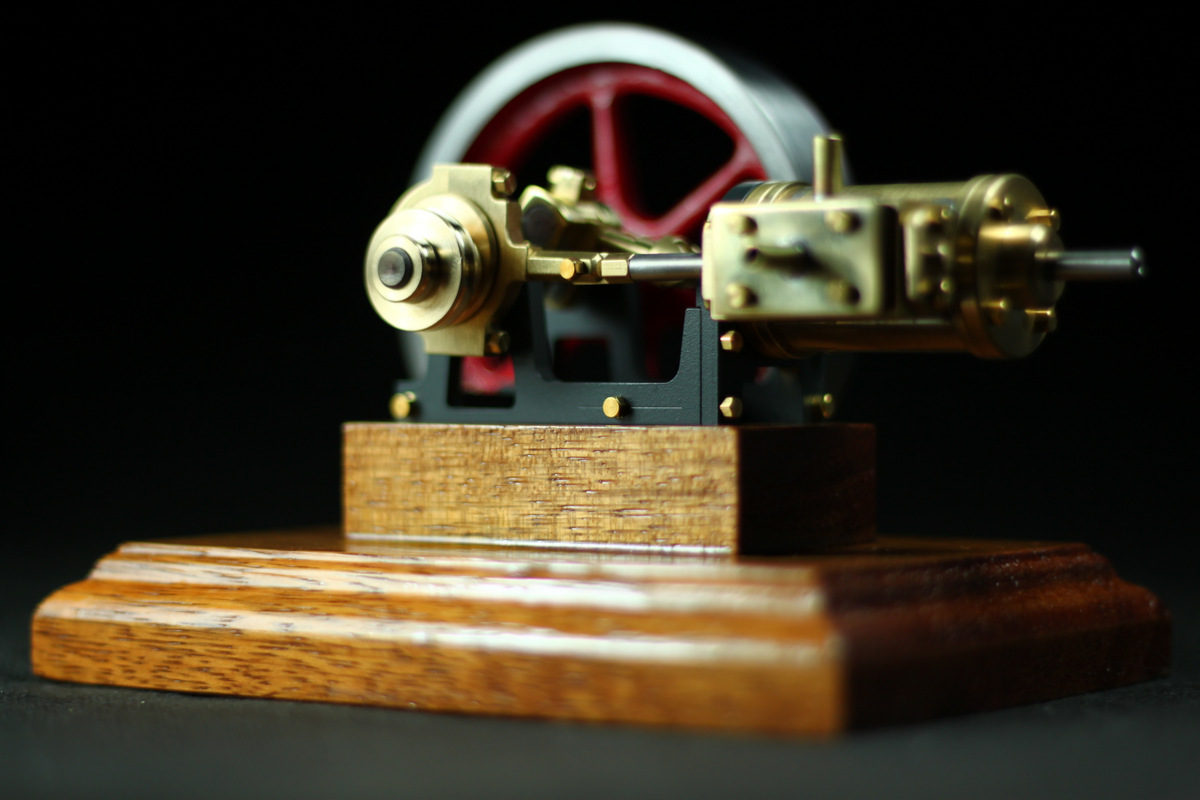

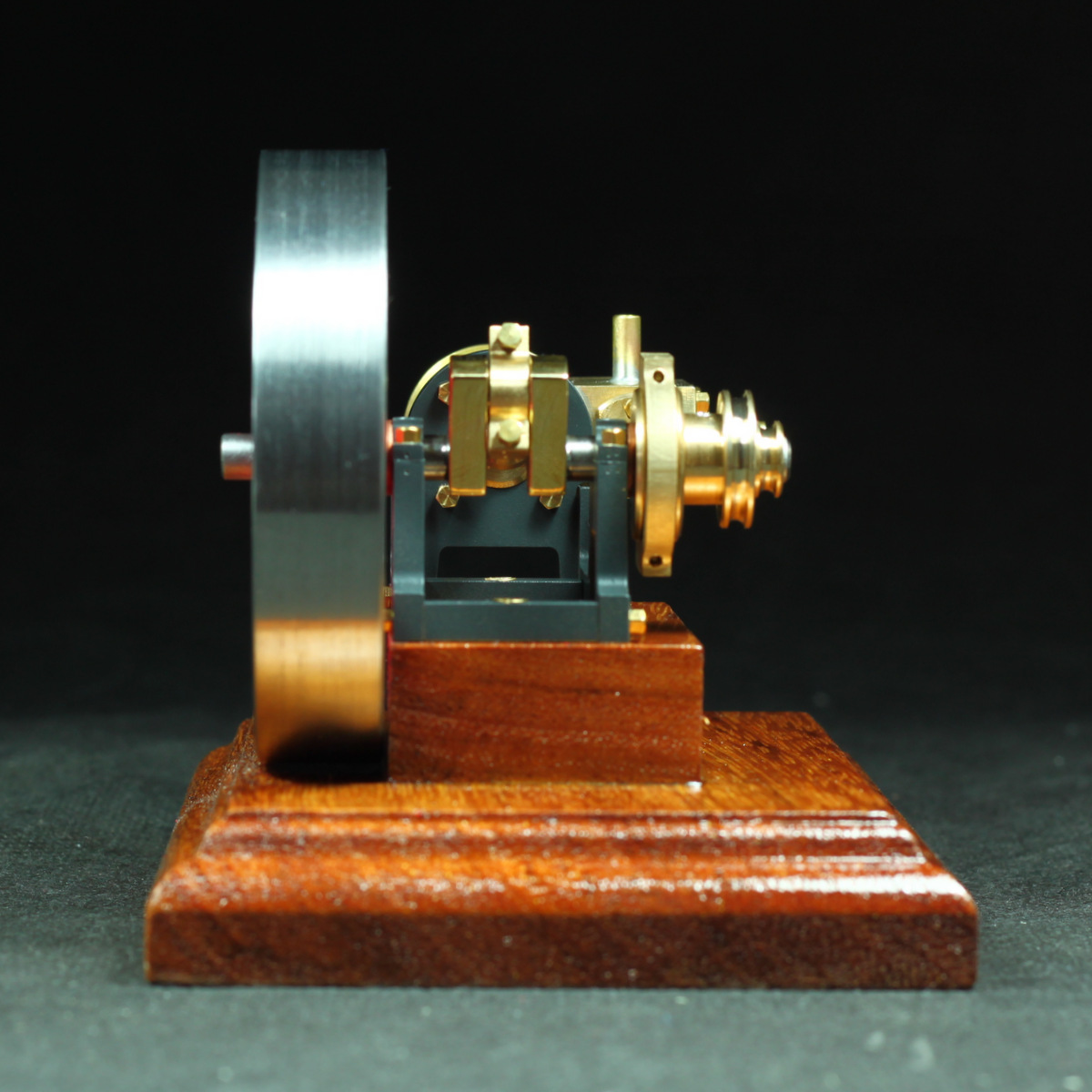

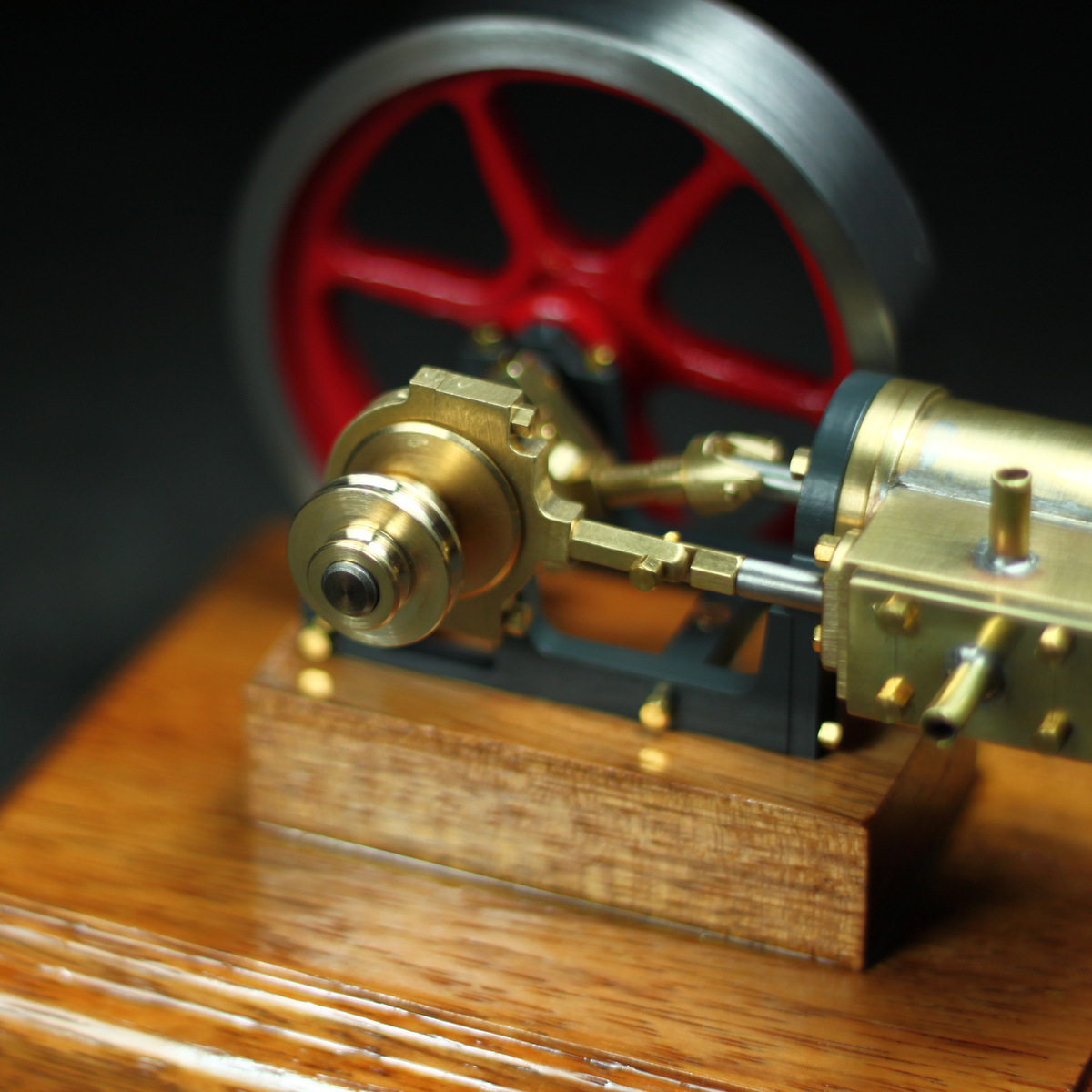

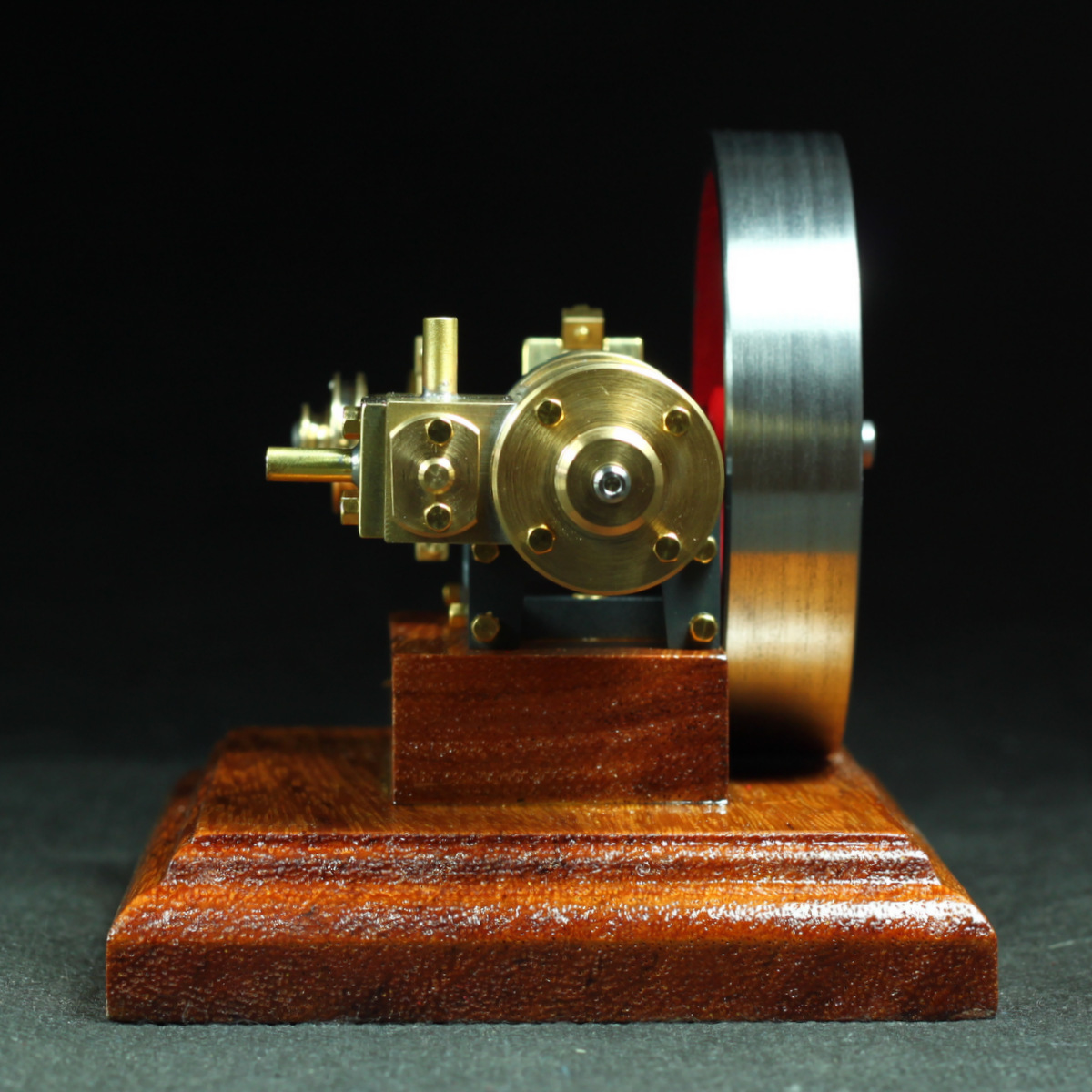

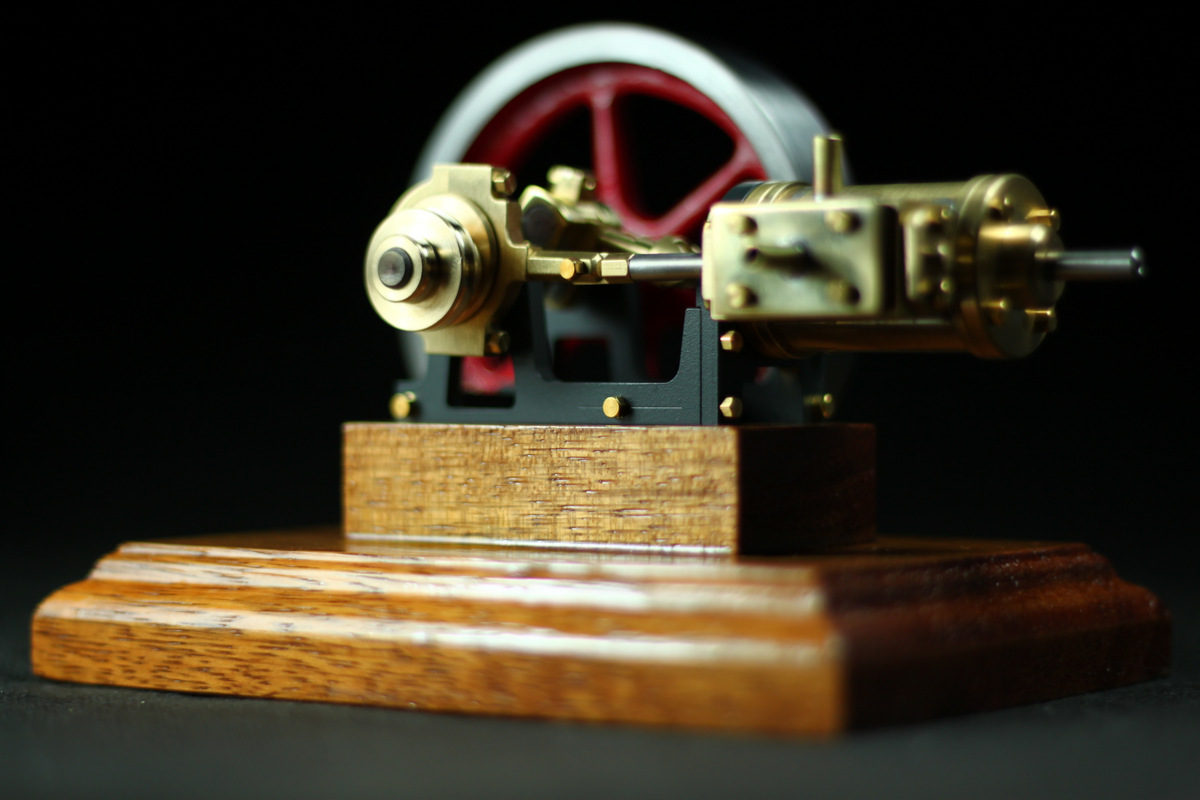

The model of the “Danni” horizontal steam engine consists of a stable frame to which the double-acting steam cylinder is connected. The cylinder of the steam engine is controlled via an eccentric and a round slide. This compact yet powerful steam engine is ideal for operation with a steam boiler, but can of course also be powered with compressed air. If the kit is carefully manufactured and without load, the machine starts running at just 0.1 bar. The “Danni” is also equipped with a cord pulley with two diameters, so that it is also very suitable for driving drive models such as circular saws, drills or hammer mills.

The construction plan and instructions for this steam engine are very comprehensive, detailed and easy to understand. This makes the kit not only suitable for model building professionals but also for newcomers to technical model building. The construction instructions go into the production of each component. For the model builder who has always been a Want to build steam engines yourself Machine "Danni" definitely a good choice. But even advanced model makers will enjoy this visually appealing single-cylinder model. It represents an interesting addition to any model machine park and definitely belongs in every collection.

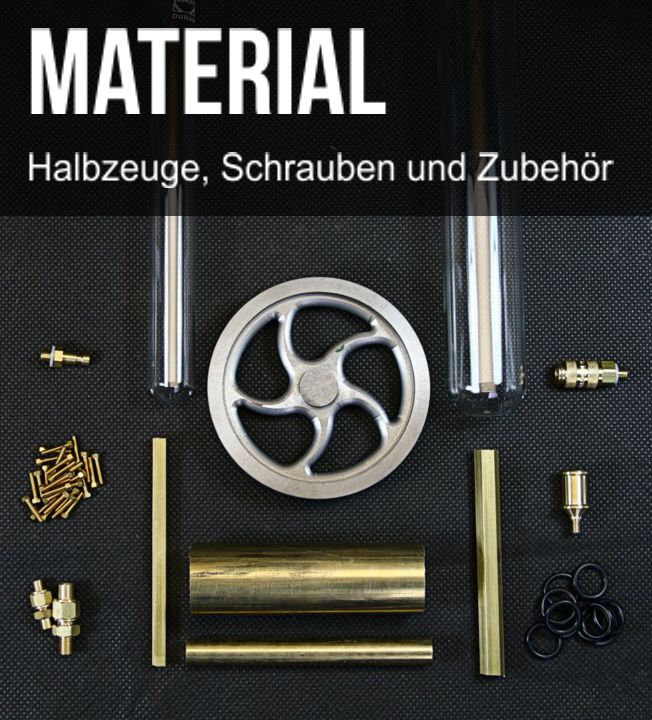

The cylinder of the model steam engine is made of brass, the piston is made of bronze. Piston rods and sliders are made of stainless steel and the flywheel is made of cast iron. All other parts are made of brass, as proven in steam model making. The flywheel was manufactured in steel casting using the lost wax process, it is extremely precise and cleanly cast.

Included in the scope of delivery of the Danni steam engine material kit

- Milled oak base plate

- Finished milled parts

- Brass, bronze, stainless steel and silver steel raw material for the turned parts

- Flywheel cast steel

- All required screws, nuts and grub screws

- Construction plan model steam engine "Danni" drawings (9 sheets) and construction instructions (6 sheets)

Dimensions of Danni steam engine

- Height with base plate: 100mm

- Length with base plate: 160mm

- Width with base plate: 100mm

- Piston diameter: 15mm

- Piston stroke: 18mm

- Flywheel D.: 80mm

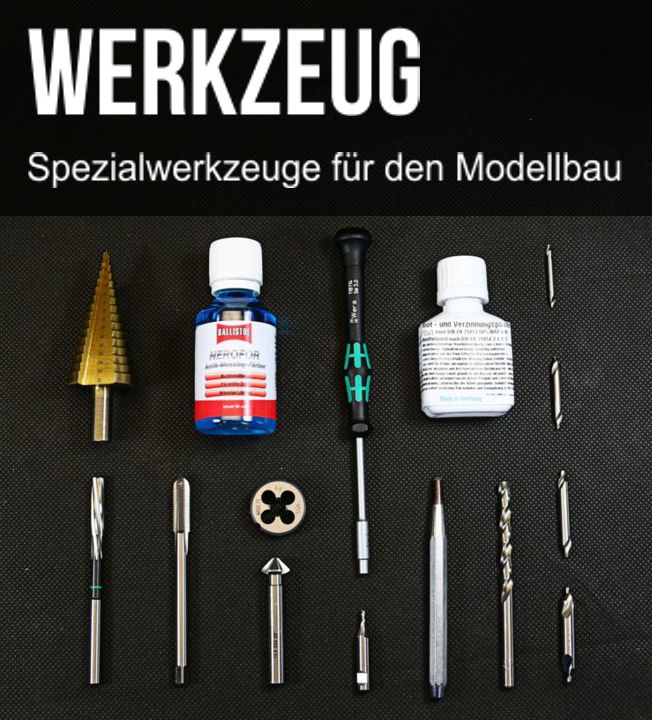

Only a few tools are needed to build the “Danni” steam engine material kit. A small lathe and a small drill are completely sufficient. If you choose the cast flywheel, your lathe should be large enough to turn an 80mm flywheel on the outside. If this is not the case, select the milled flywheel that is already finished on the outside diameter. There should also be a gas burner for soldering larger parts. M2 and M3 taps and M2 and M3 cutting dies are also needed. You also need reamers 4H7, 6H7, files and a drill set.

A detailed Construction report on the steam engine “Danni” can be found in our Bengs model building magazine. On the page you will find many pictures and texts with details and suggestions on how the components of the steam engine can be manufactured.

0 of 0 reviews

Login

Cutsomers also bought