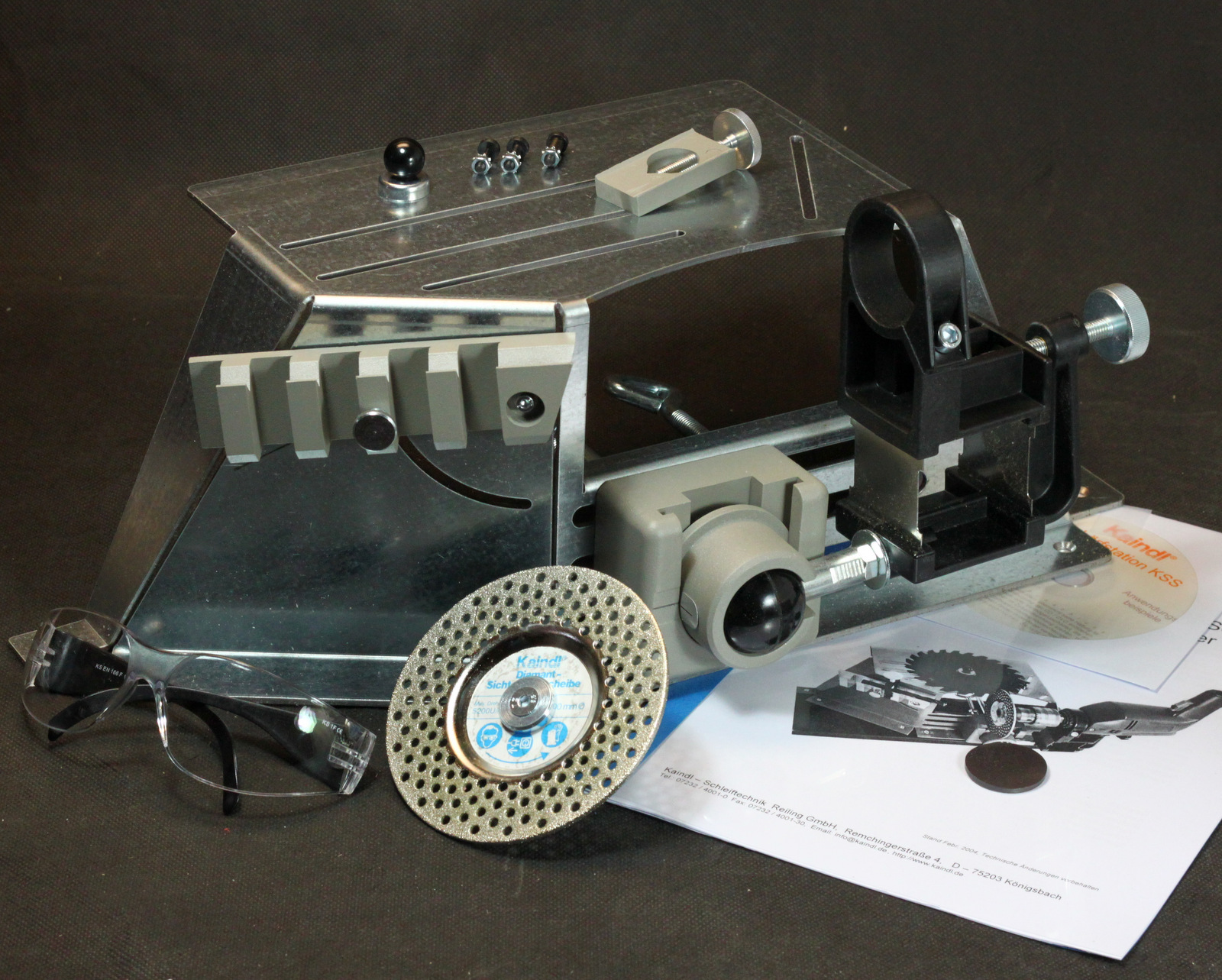

Kaindl sharpening station KSS

The Kaindl Schleiftechnik company produces high-quality products for craftsmen. All Kaindl products are “Made in Germany”. You can order the items quickly, directly and cheaply in our shop.

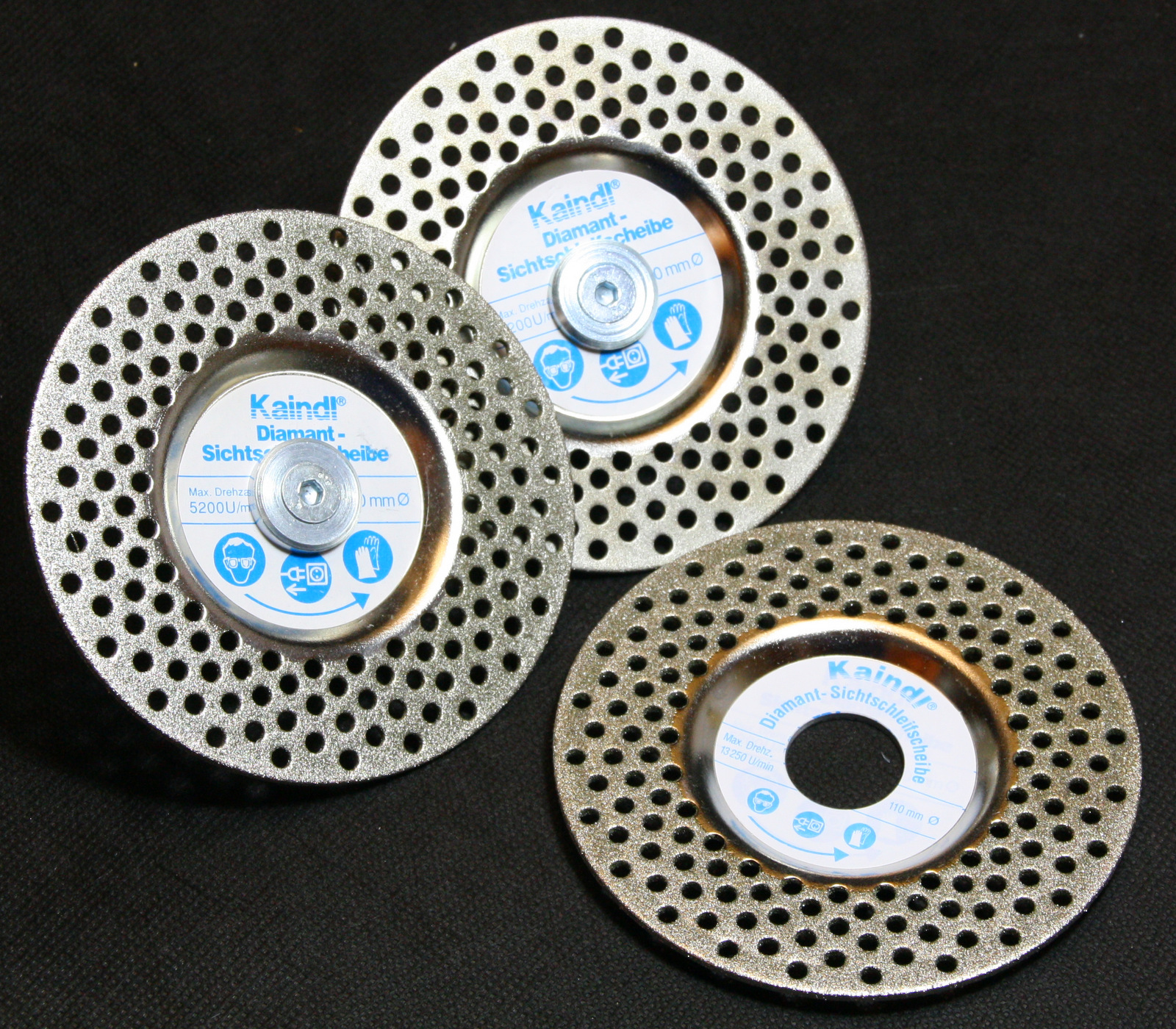

Kaindl sharpening station KSS including diamond viewing grinding wheel

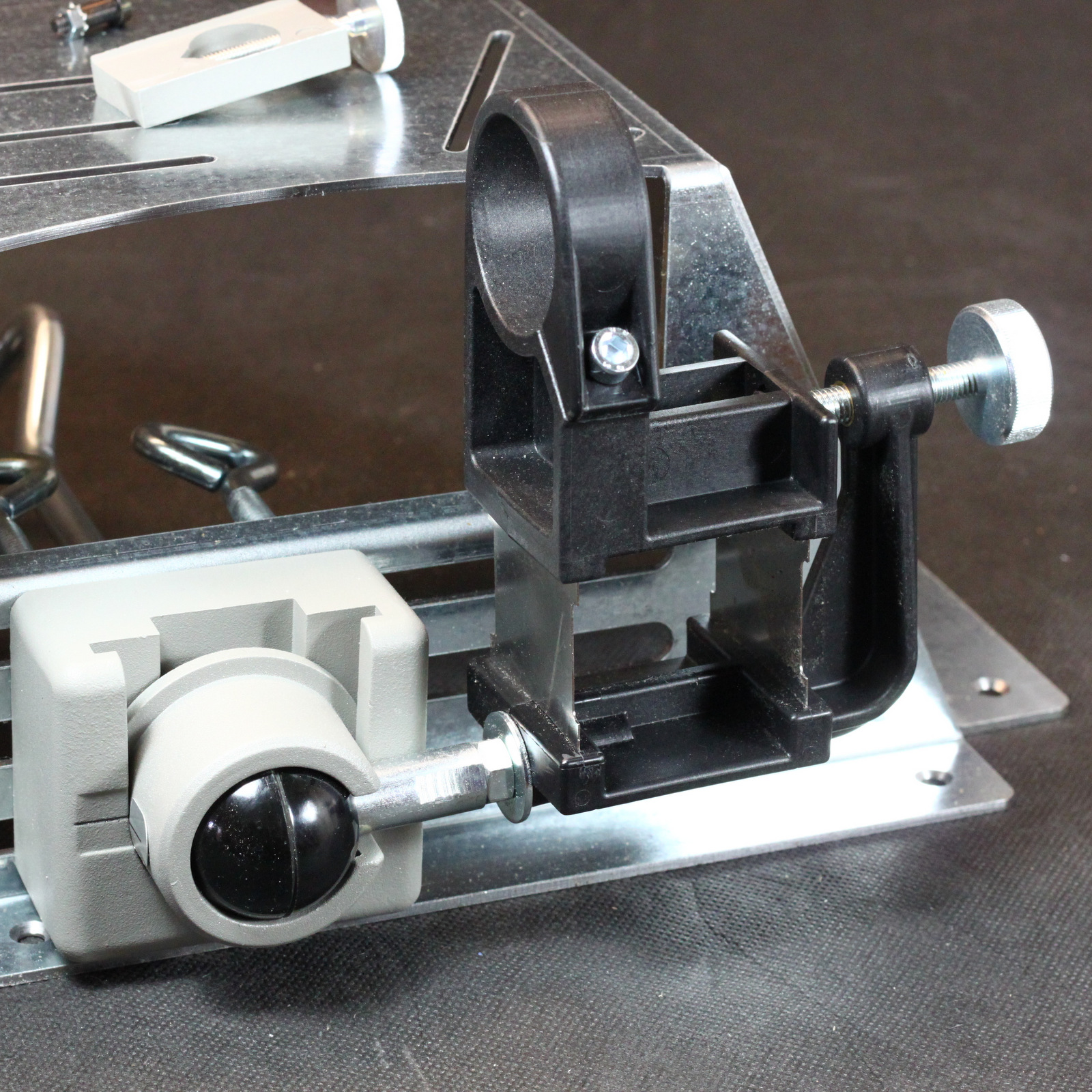

The sharpening station newly developed by Kaindl saves you from purchasing significantly more expensive machines to sharpen your tools. Thanks to the new and very flexible design, it is now possible to sharpen a wide variety of drills, milling cutters, turning tools and saw blades. Saw blades, regardless of whether they are made of HSS, carbide or chrome vanadium, can be re-sharpened again and again with very high precision and ensuring a consistent tooth pitch. HSS and carbide drills up to 16mm are sharpened with the four-surface grind, which is advantageous for DIY enthusiasts and craftsmen. This makes drilling on smooth surfaces and curves easier, among other things. It is not necessary to sharpen the cross cutting edge. You can order the KSS grinding station from Kaindl either with or without a diamond visible grinding wheel.

Included in delivery:

- Sharpening station including 3 stops and drill grinding device

- interactive DVD instructions

- Kaindl safety glasses

- optionally including Kaindl diamond sight grinding wheel with notch

Login