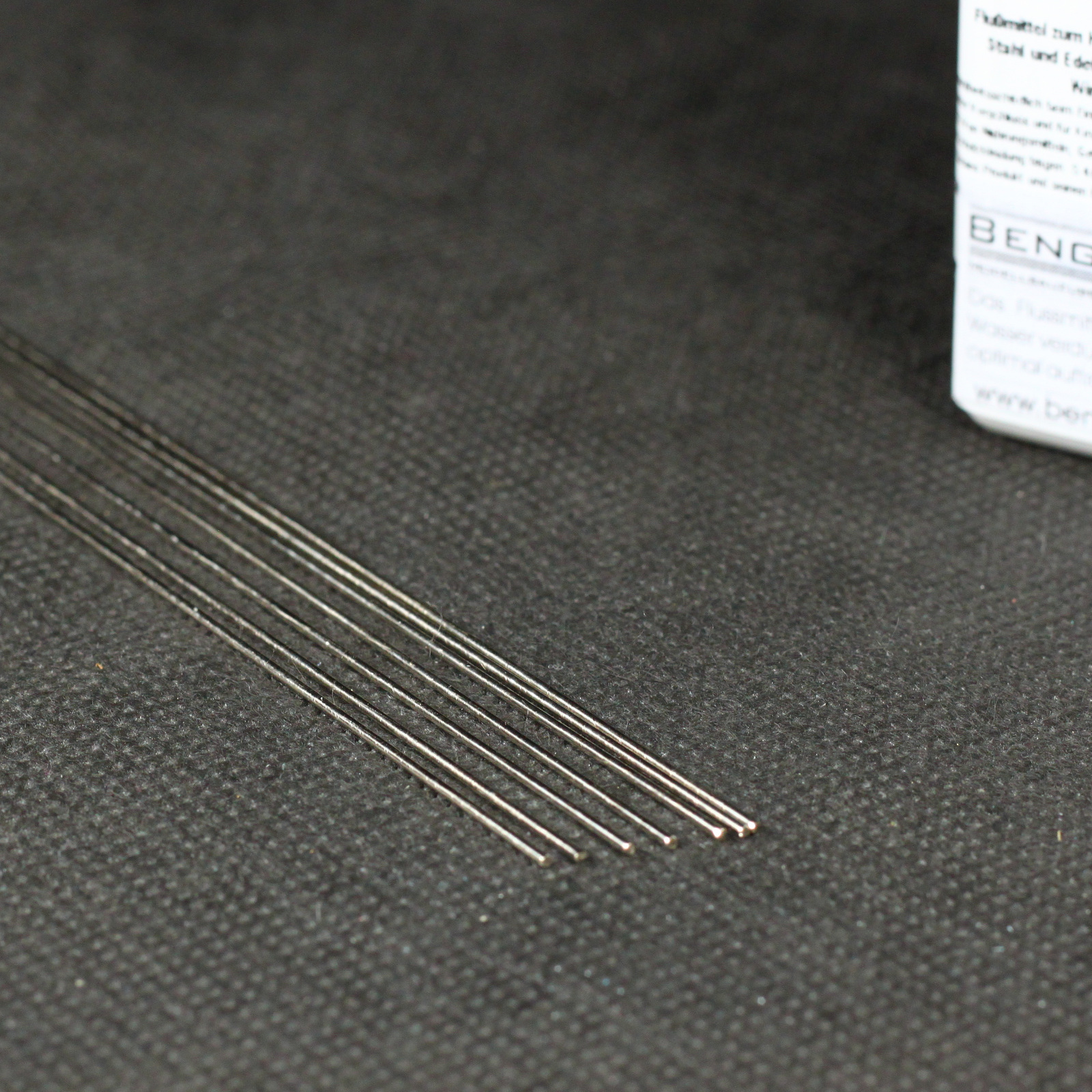

Soldering wire for soft soldering stainless steel

€7.70*

Available, delivery time: 1-3 days

Special soldering wire for soft soldering stainless steel and steel but also non-ferrous metals such as brass and copper. Very easy to use and all metals mentioned can be combined with each other. The flux contained in the wire is characterized by high temperature resistance. Optimum wetting on a wide variety of stainless steel makes this lead-free soft solder wire a top product. The use of additional flux is usually not necessary. The soft solder remains shiny even after long-term use of the soldered workpieces and has a very good color match to stainless steel.

Processing instructions for soft soldering stainless steel

Heat the components to be connected with the soldering torch to approx. 250°C and feed the wire. The flux flows out of the wire and spreads to the soldering point. The solder melts and wets the material where the flux could previously work. Then let the component cool down and remove any flux residue with water. Only suitable for 1.4301, 1.4305 or similarly alloyed stainless steels. Not suitable for higher alloyed (V4A) stainless steel qualities.

Technical information soft solder for stainless steel

- Melting range: 221 °C

- Working temperature: 280C° - 350C°

- max. Continuous operating temperature: 100°C

- Low temperature resistance: - 200°C

- suitable for soldering in the field of food technology

- Lead-free

- Wire diameter: 1.5mm

- Wire length: 1000mm

Suitable for soldering the following base materials

- Stainless steel (1.4301, 1.4305)

- Copper

- Brass

- Bronze

- Steel

- Carbide metals

- and connections of the materials mentioned with one another

Login