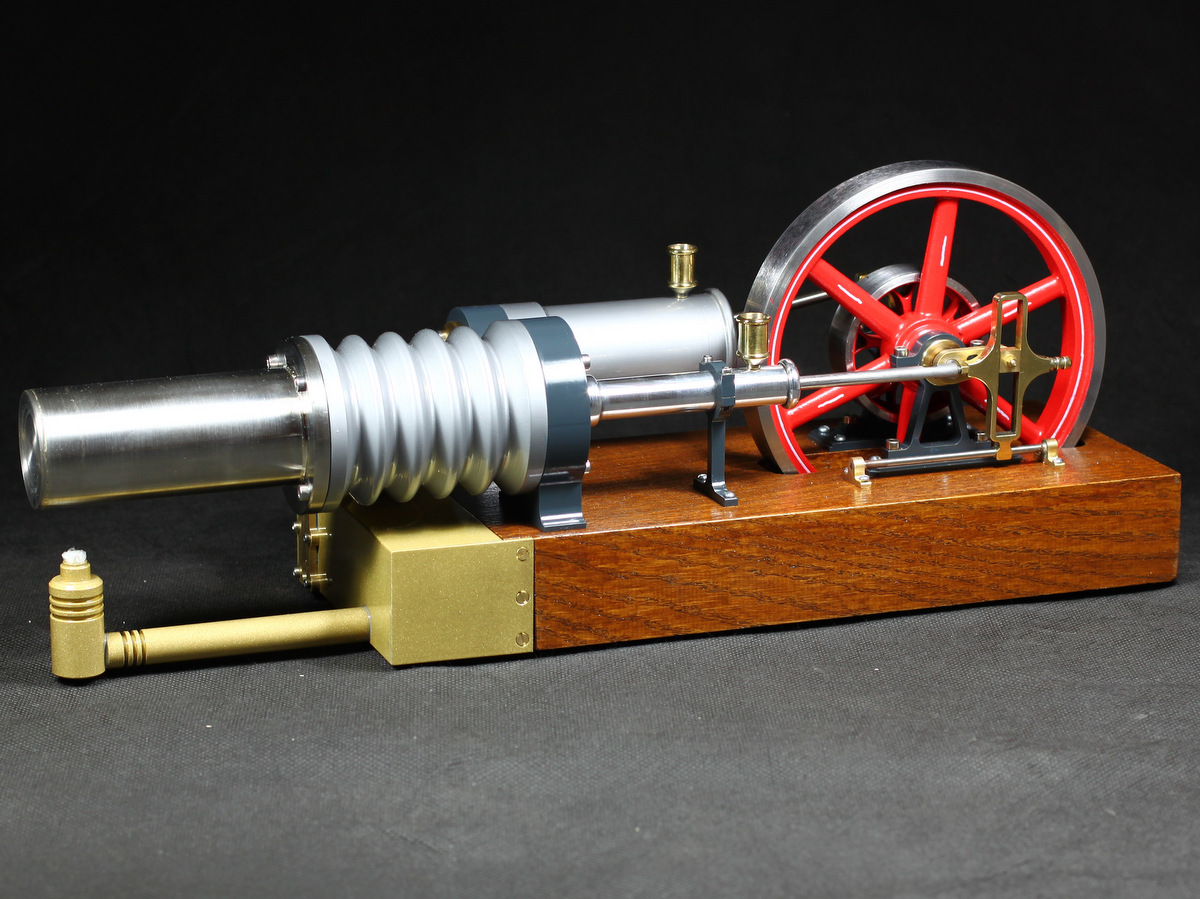

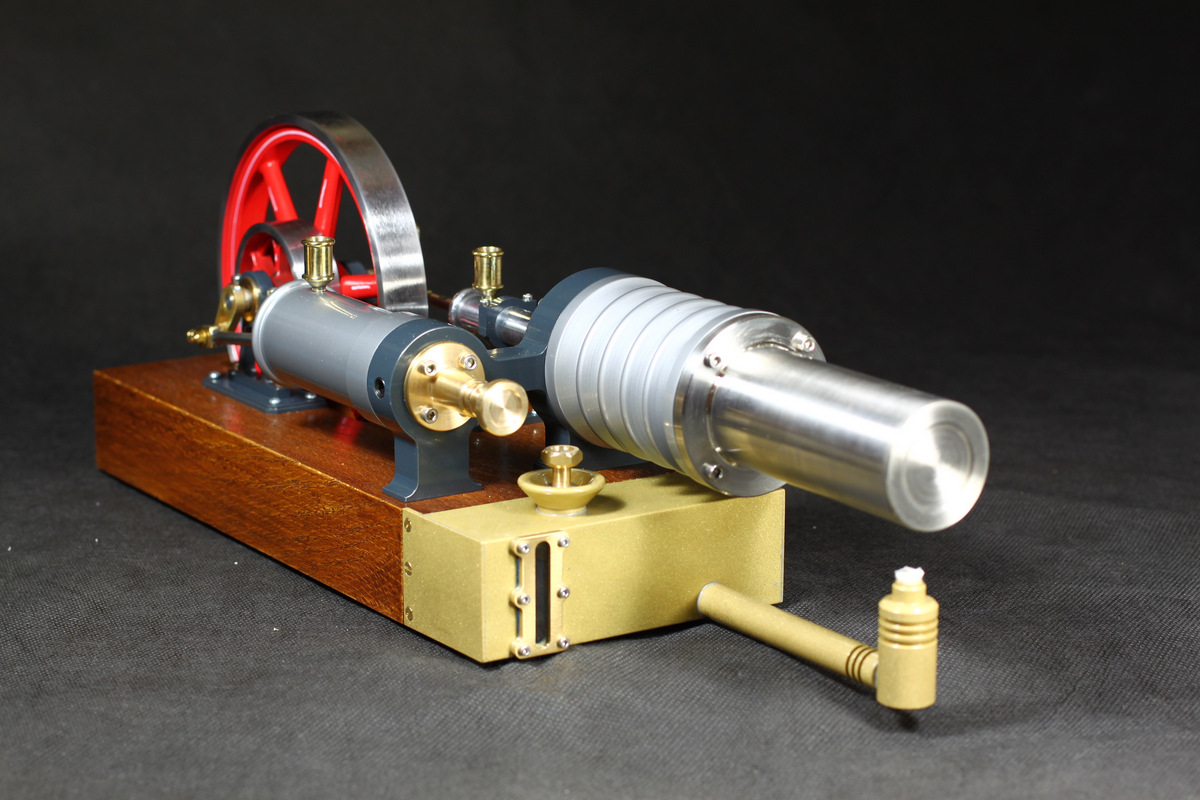

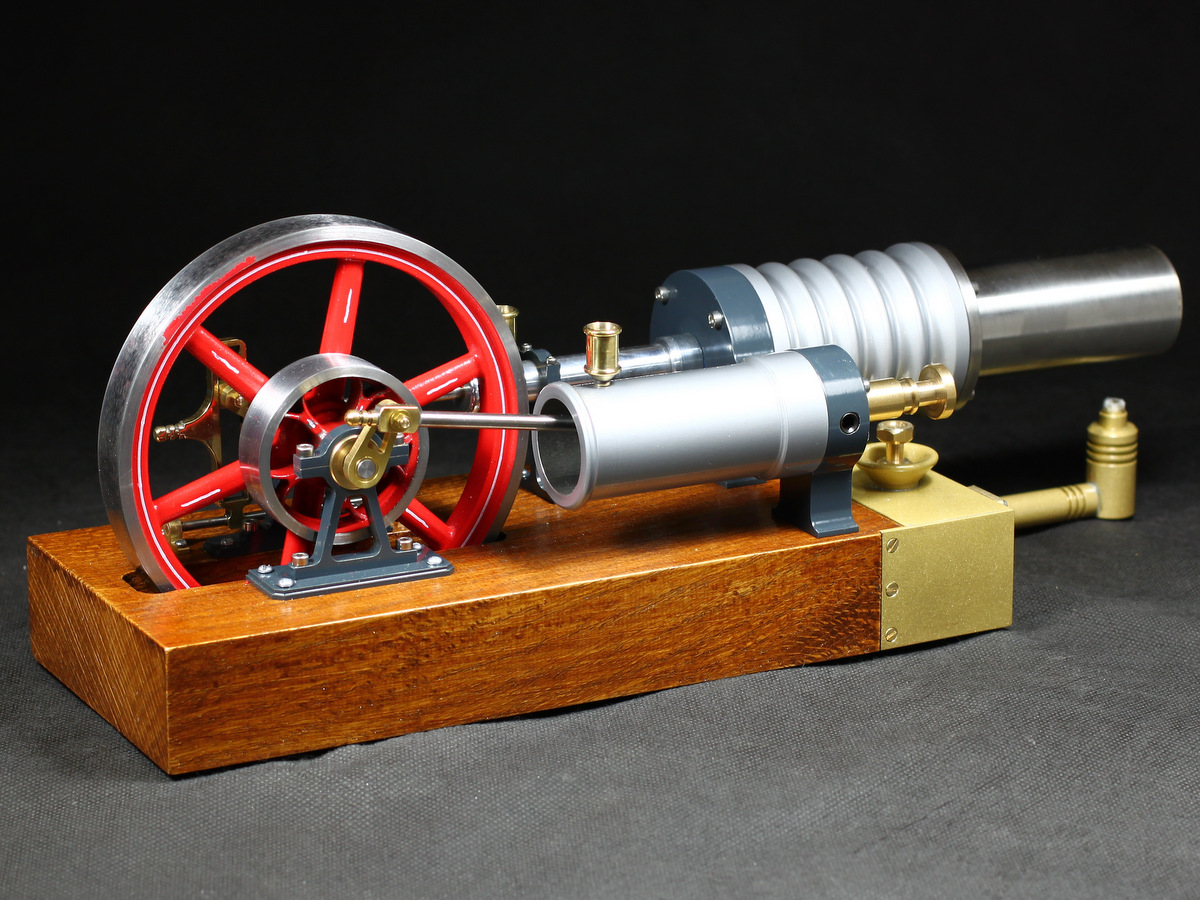

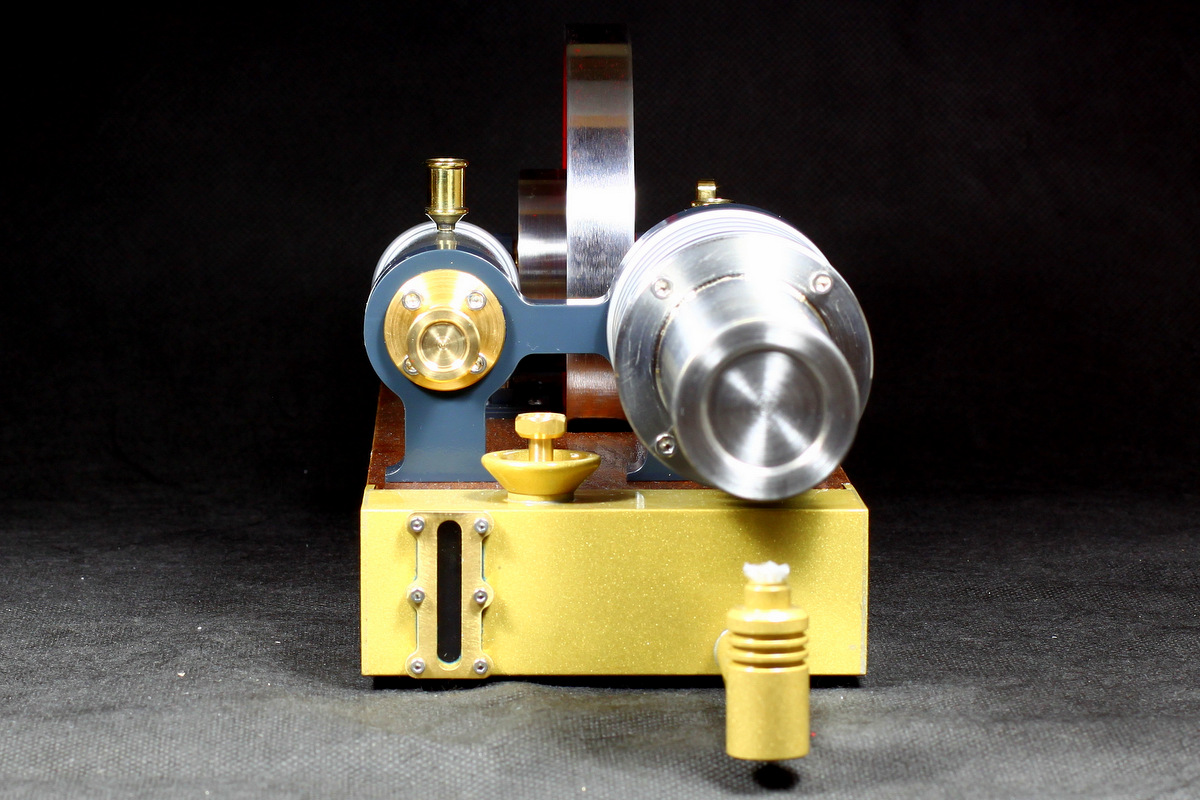

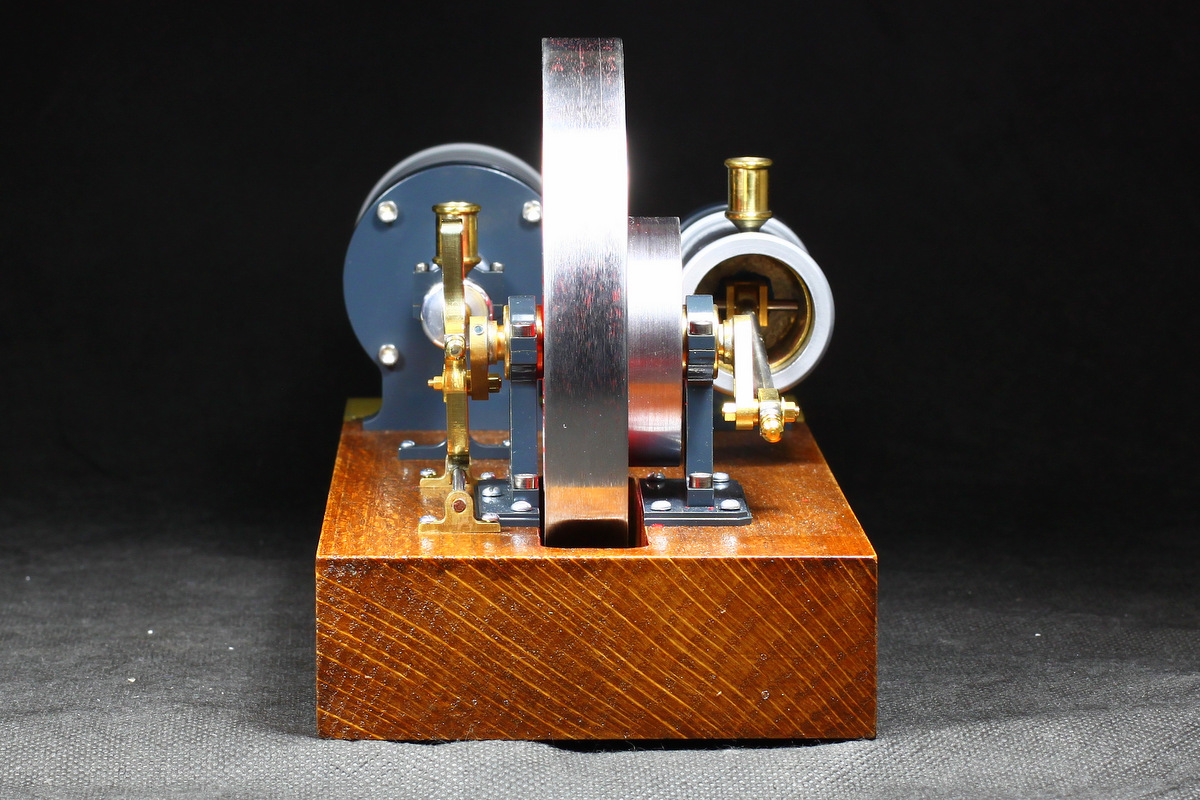

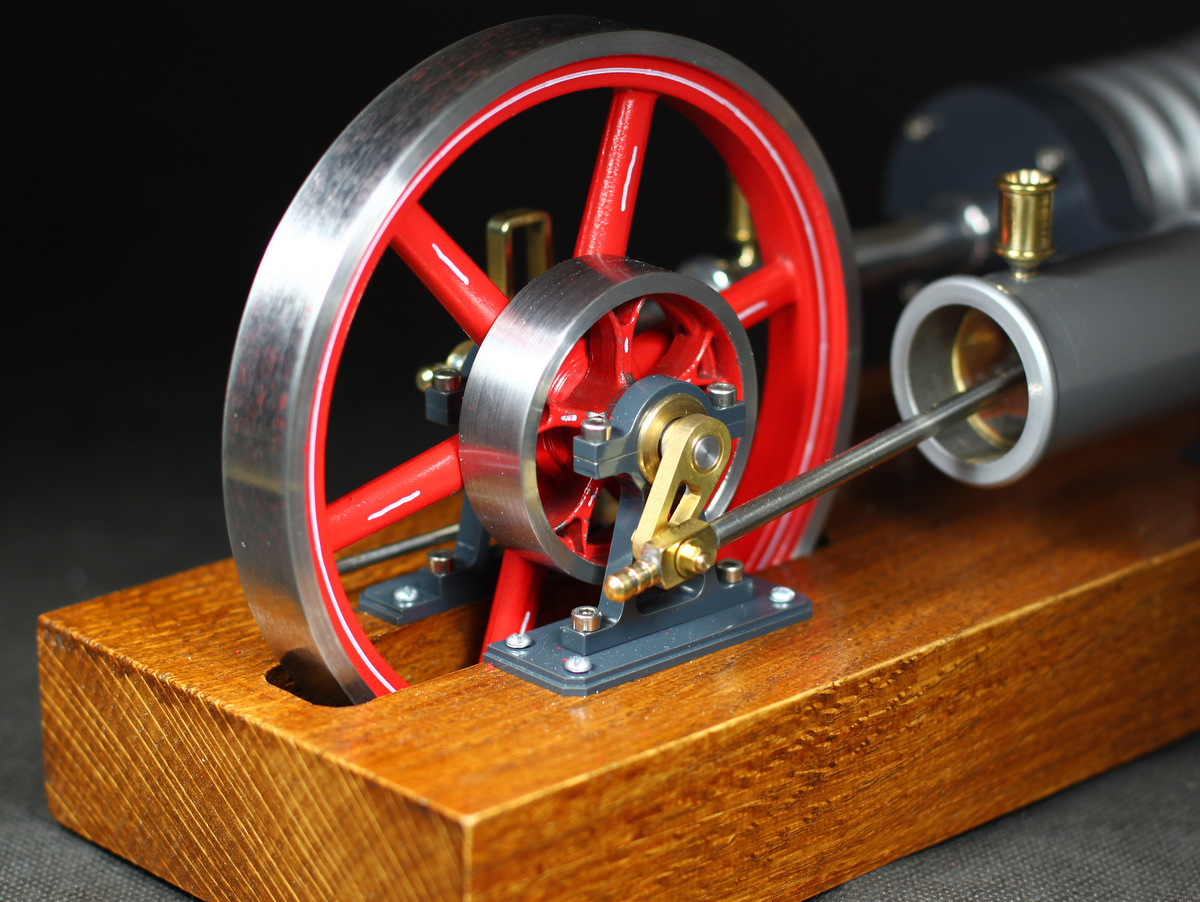

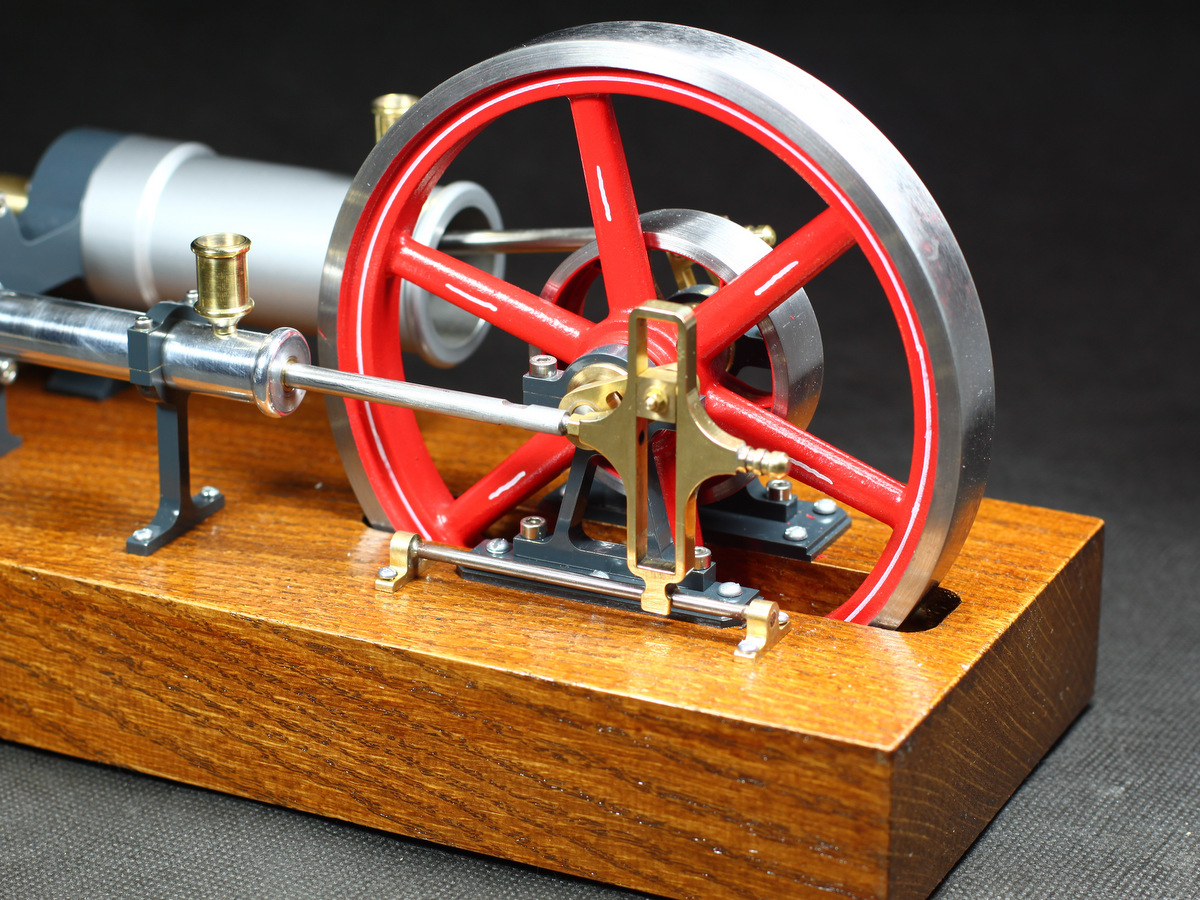

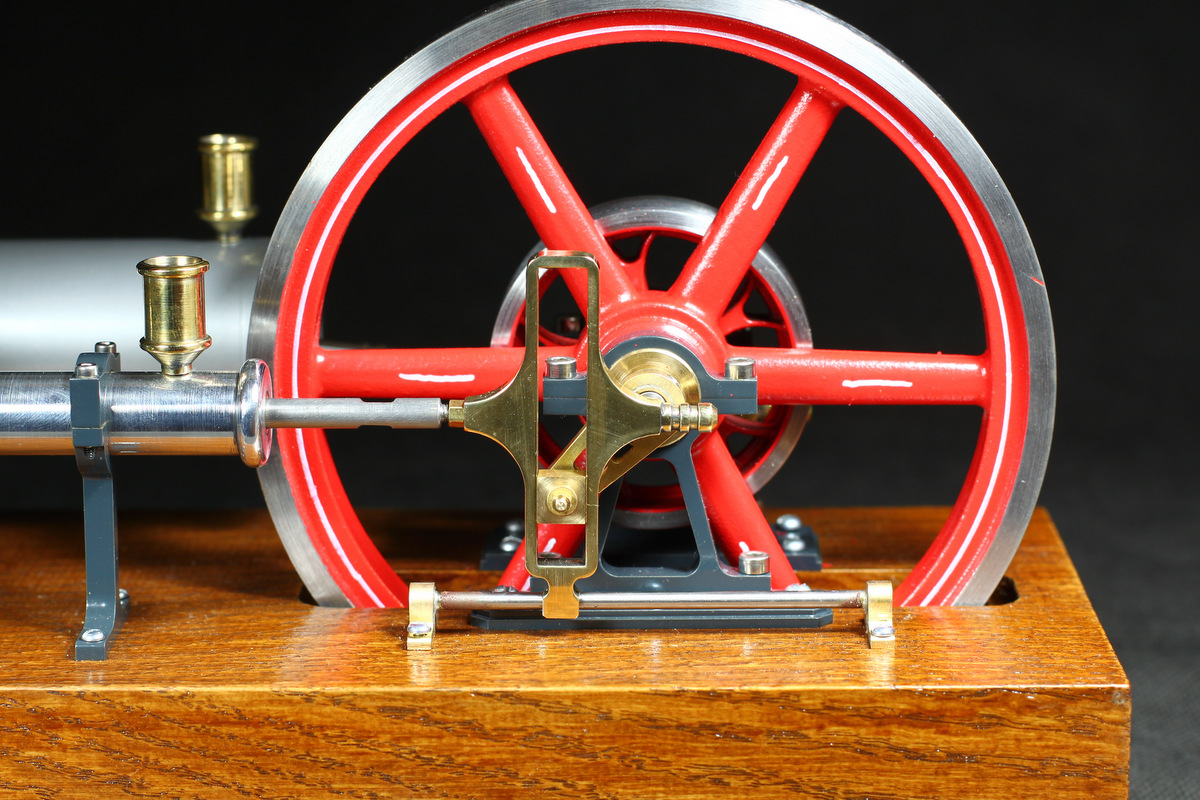

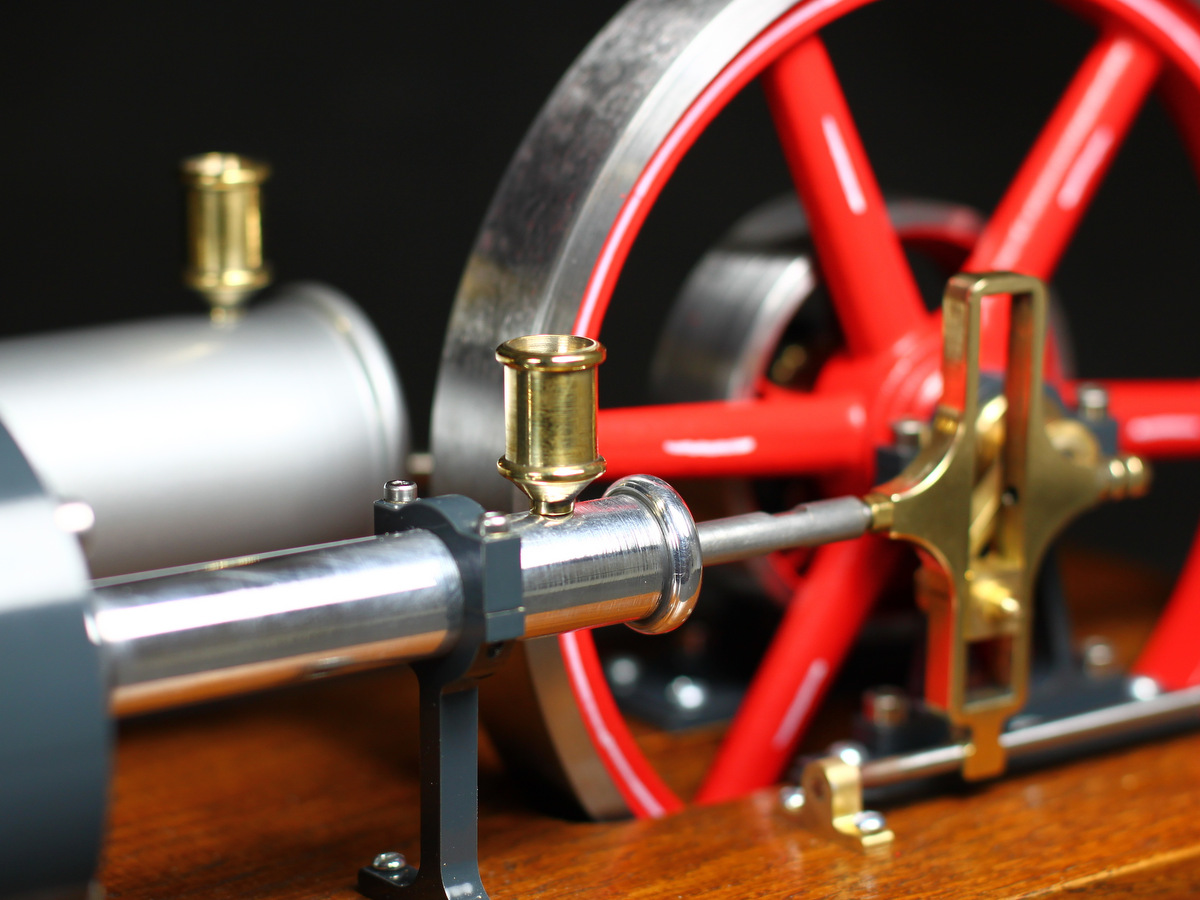

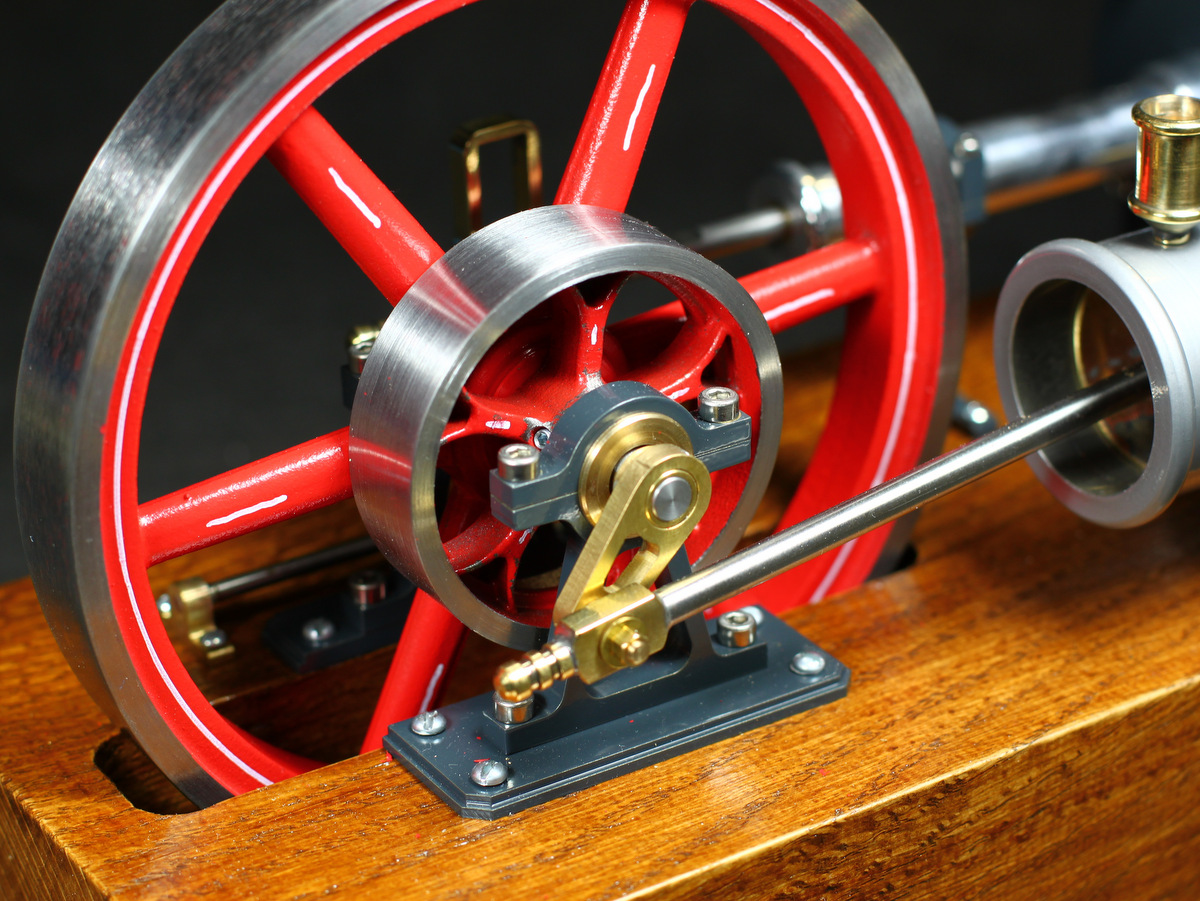

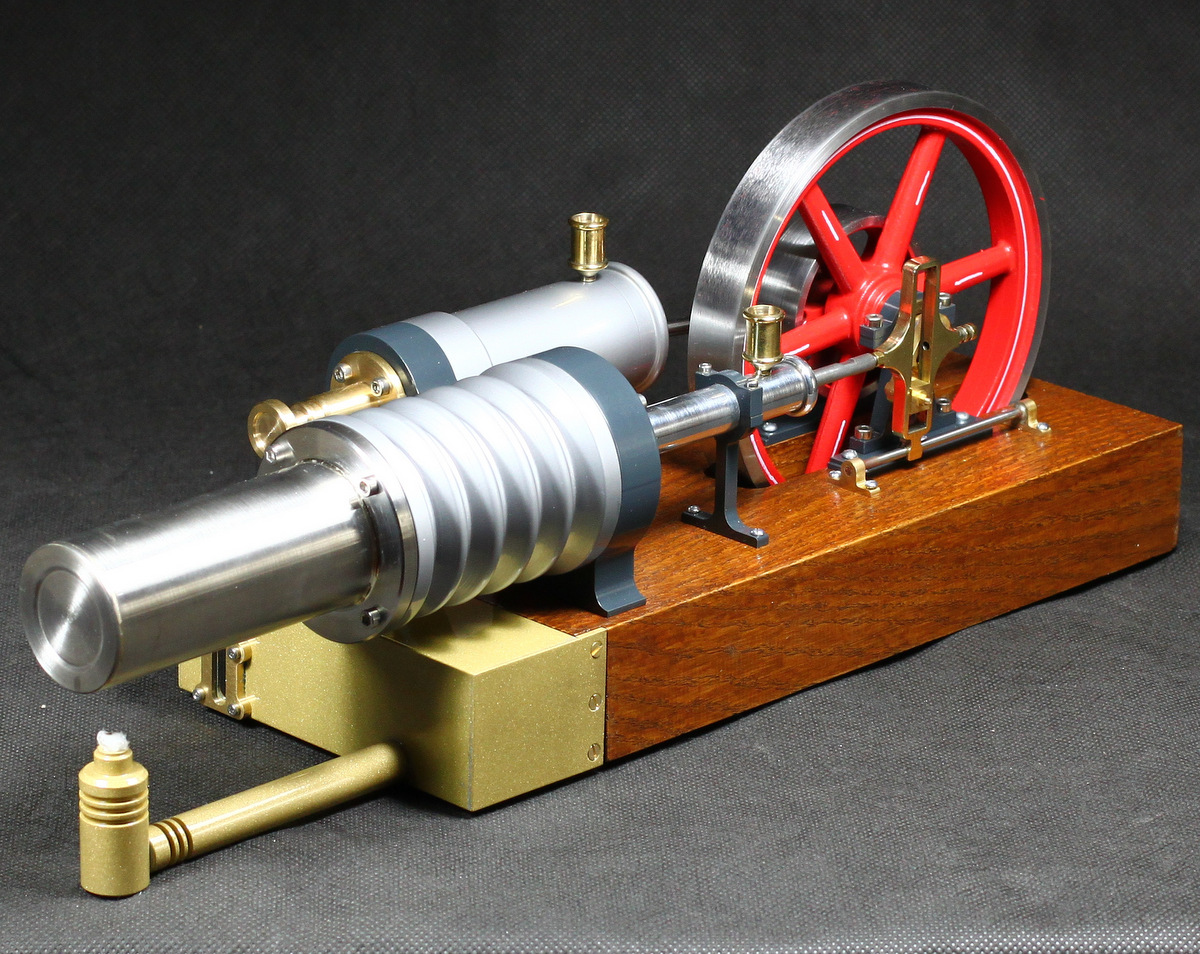

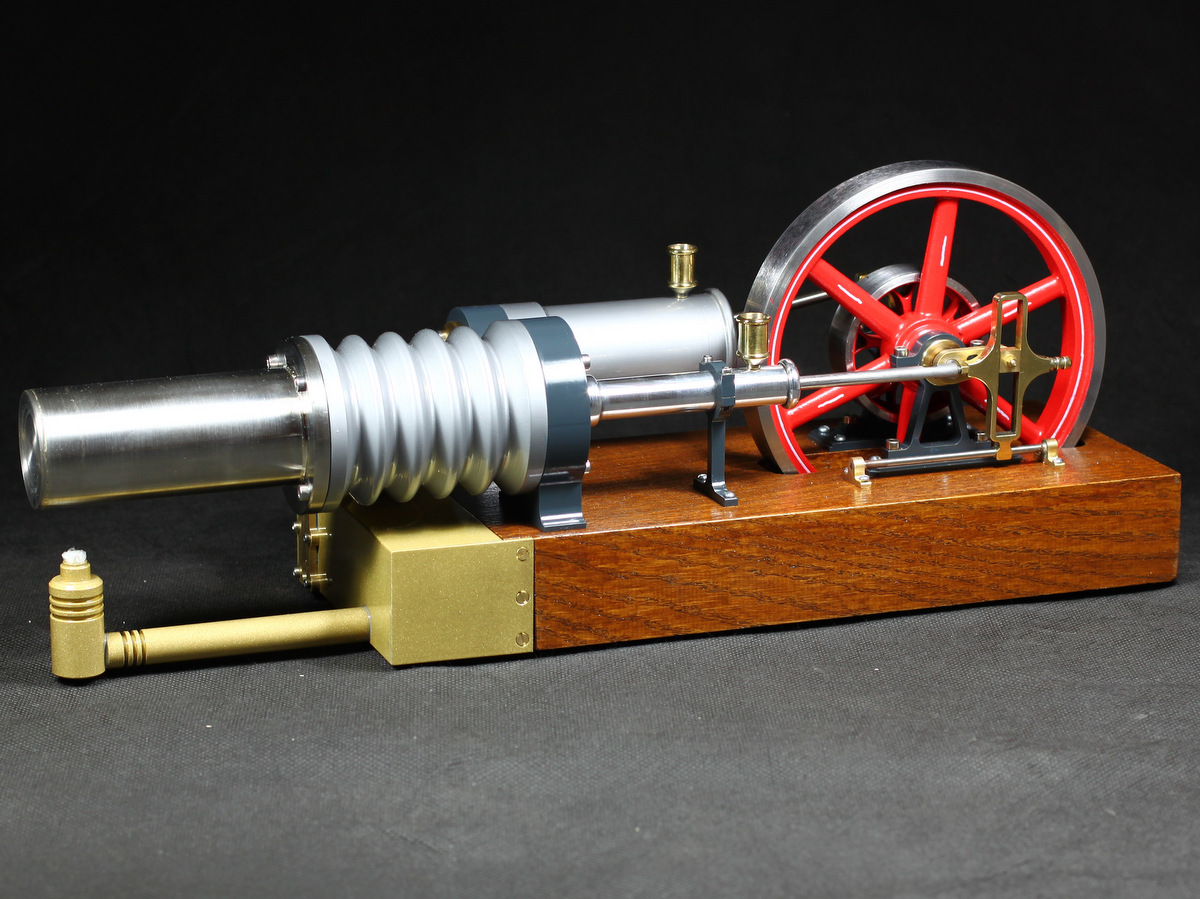

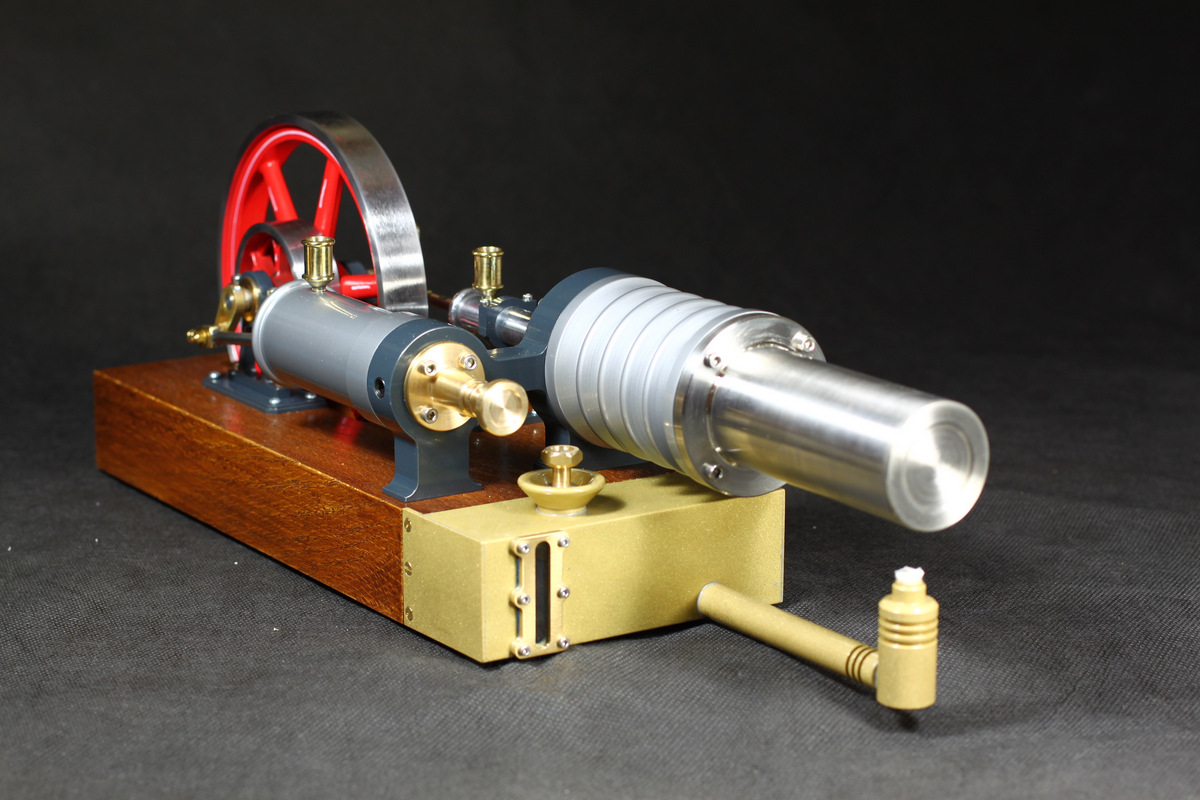

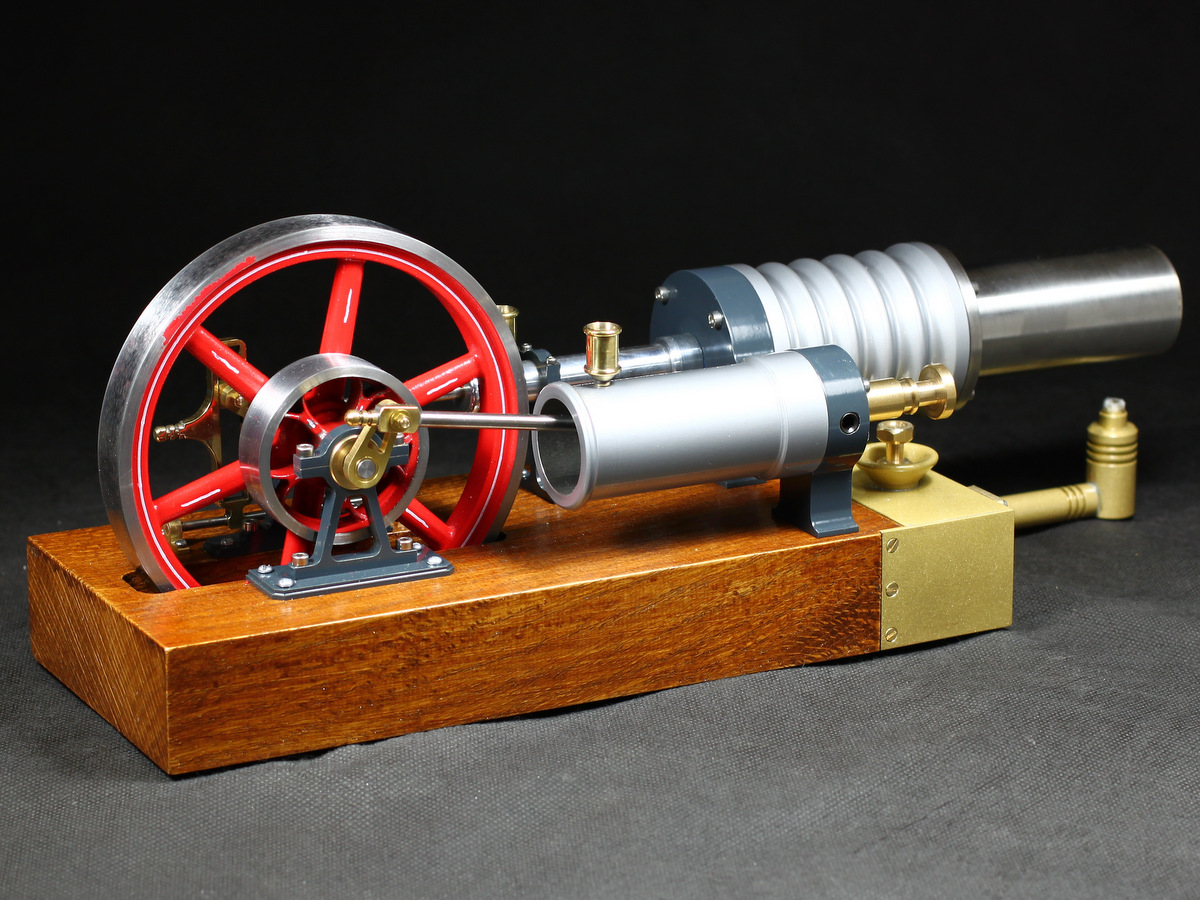

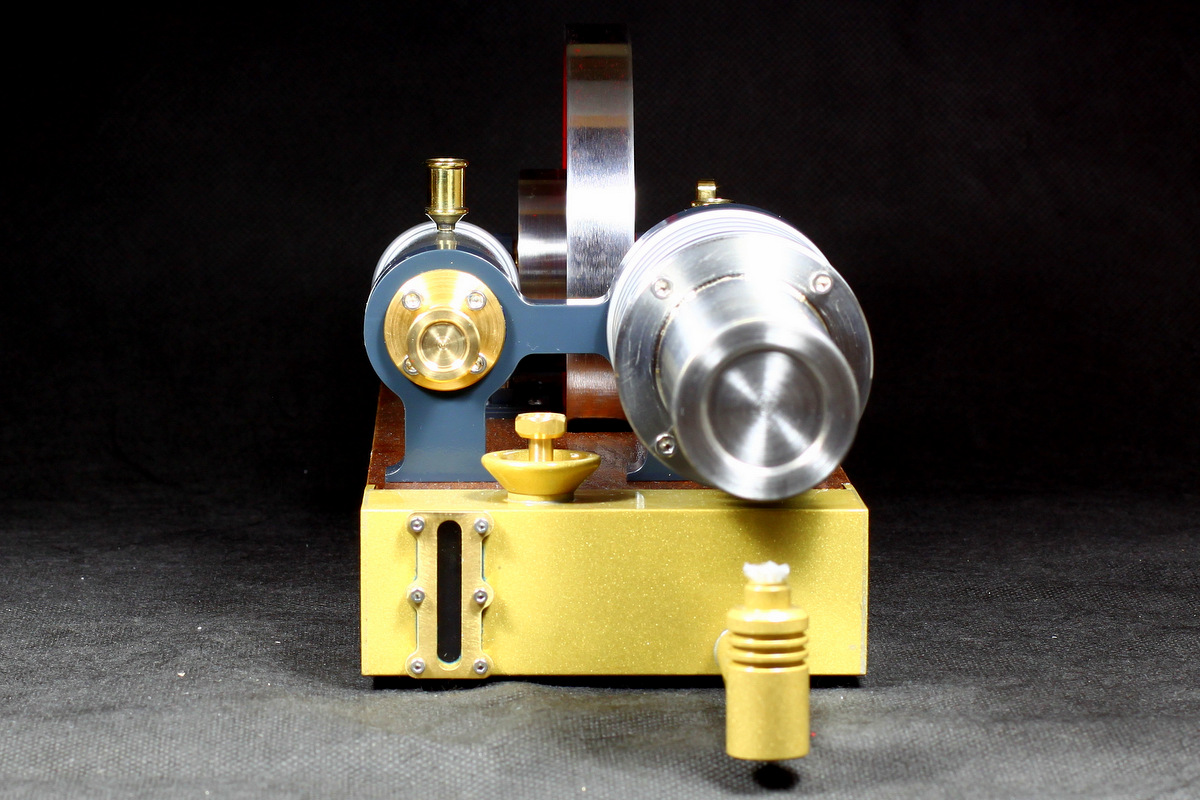

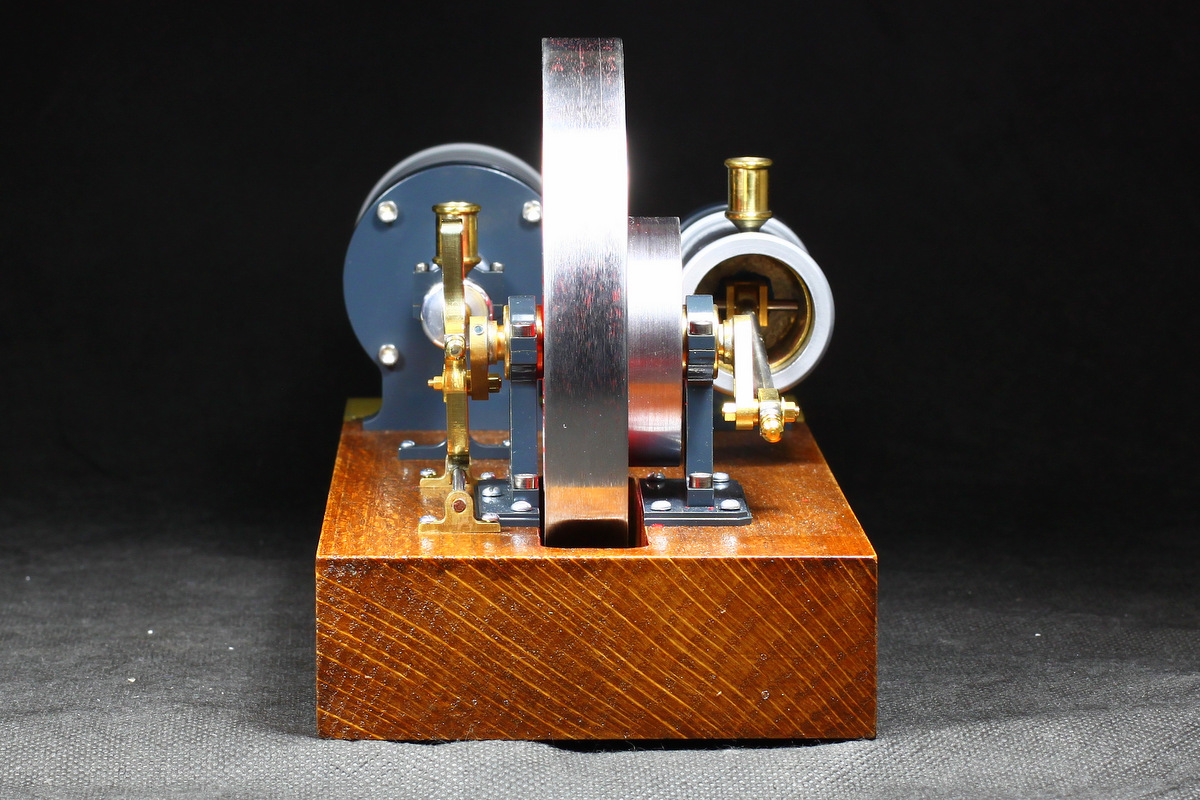

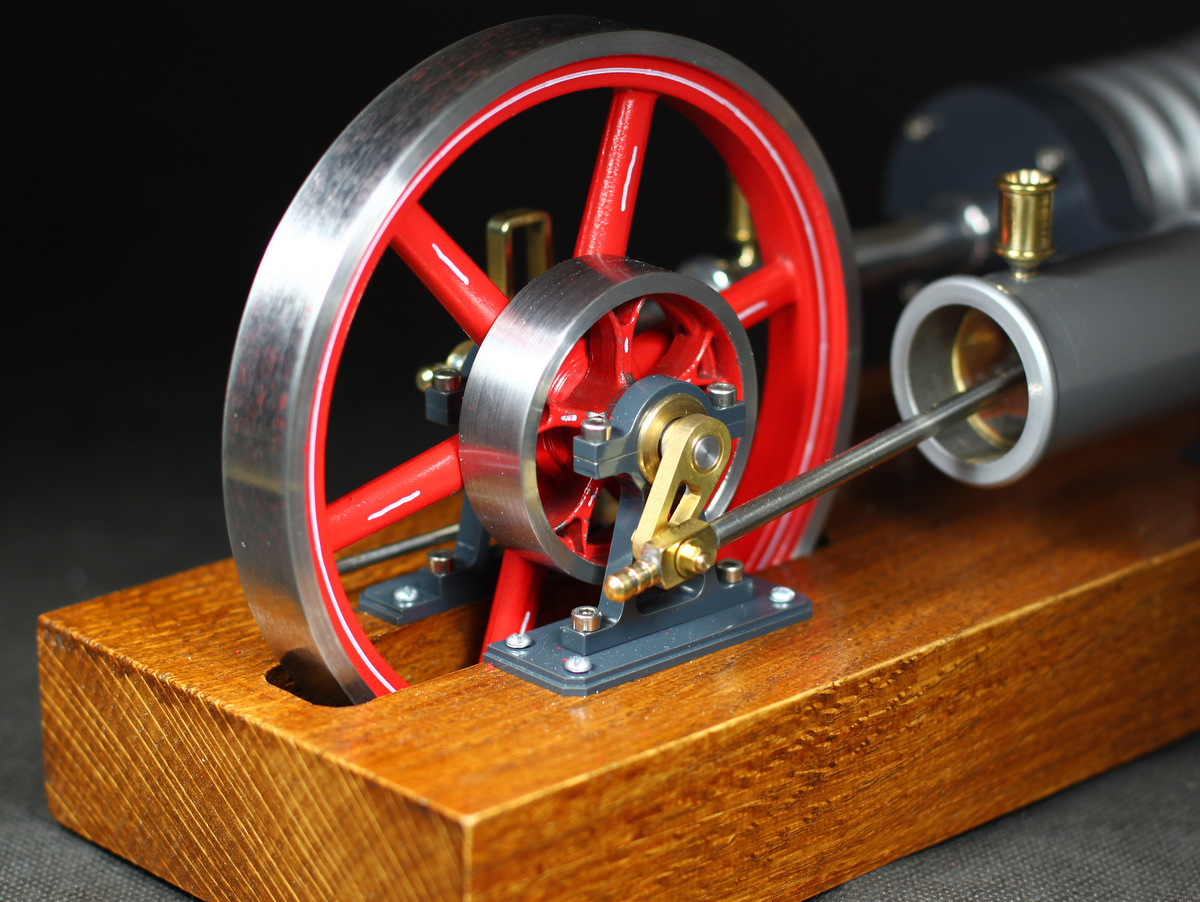

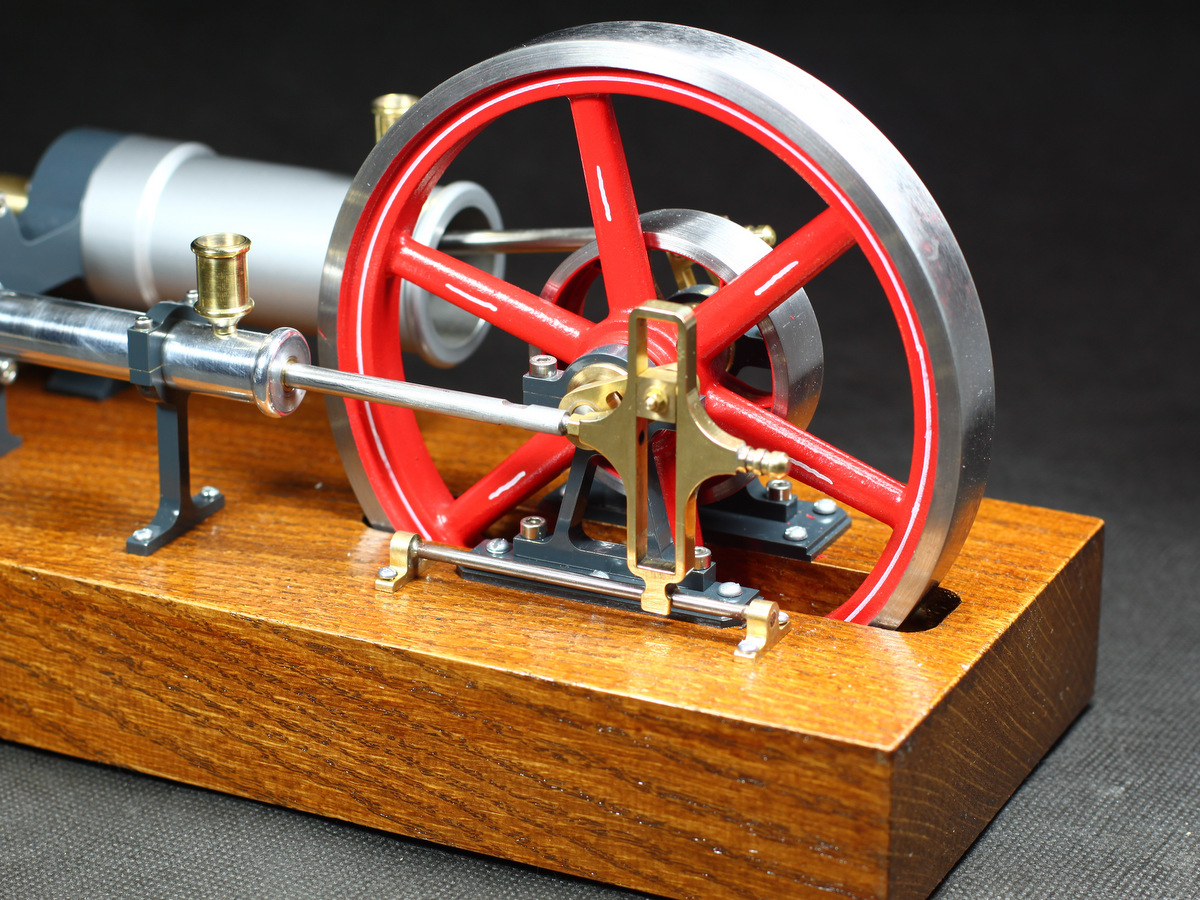

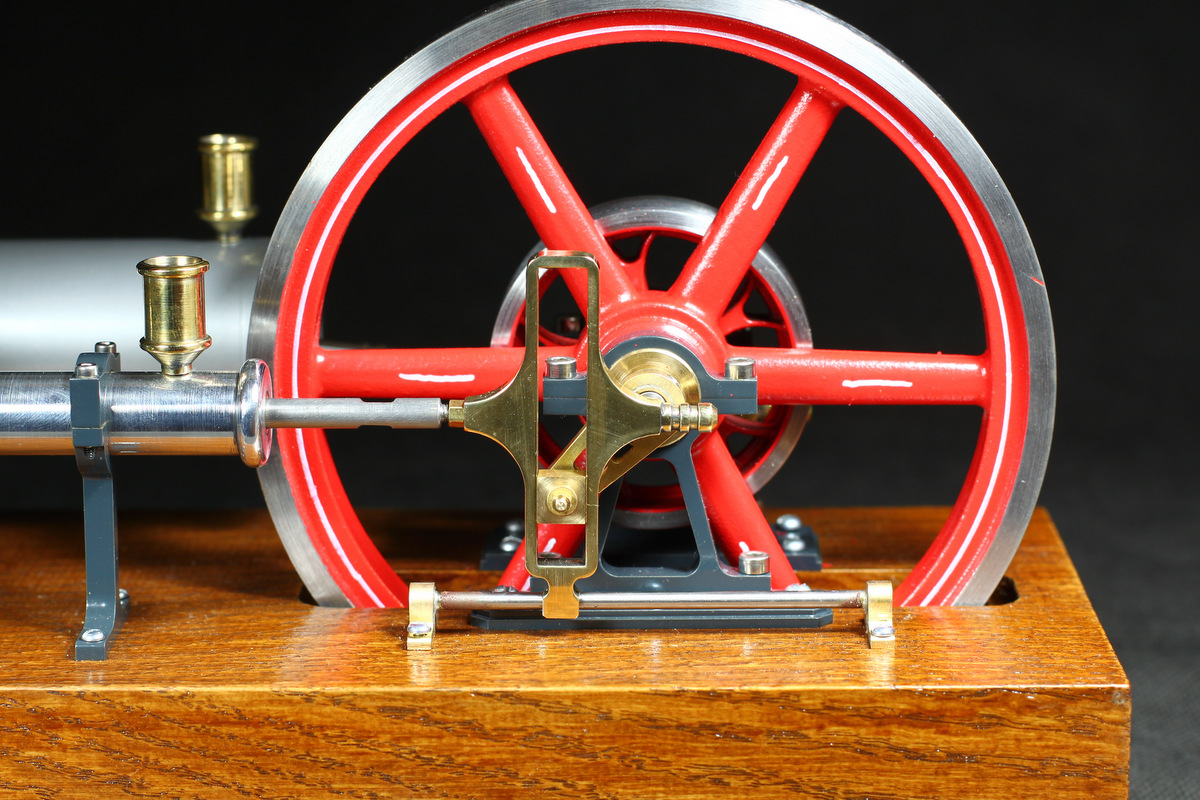

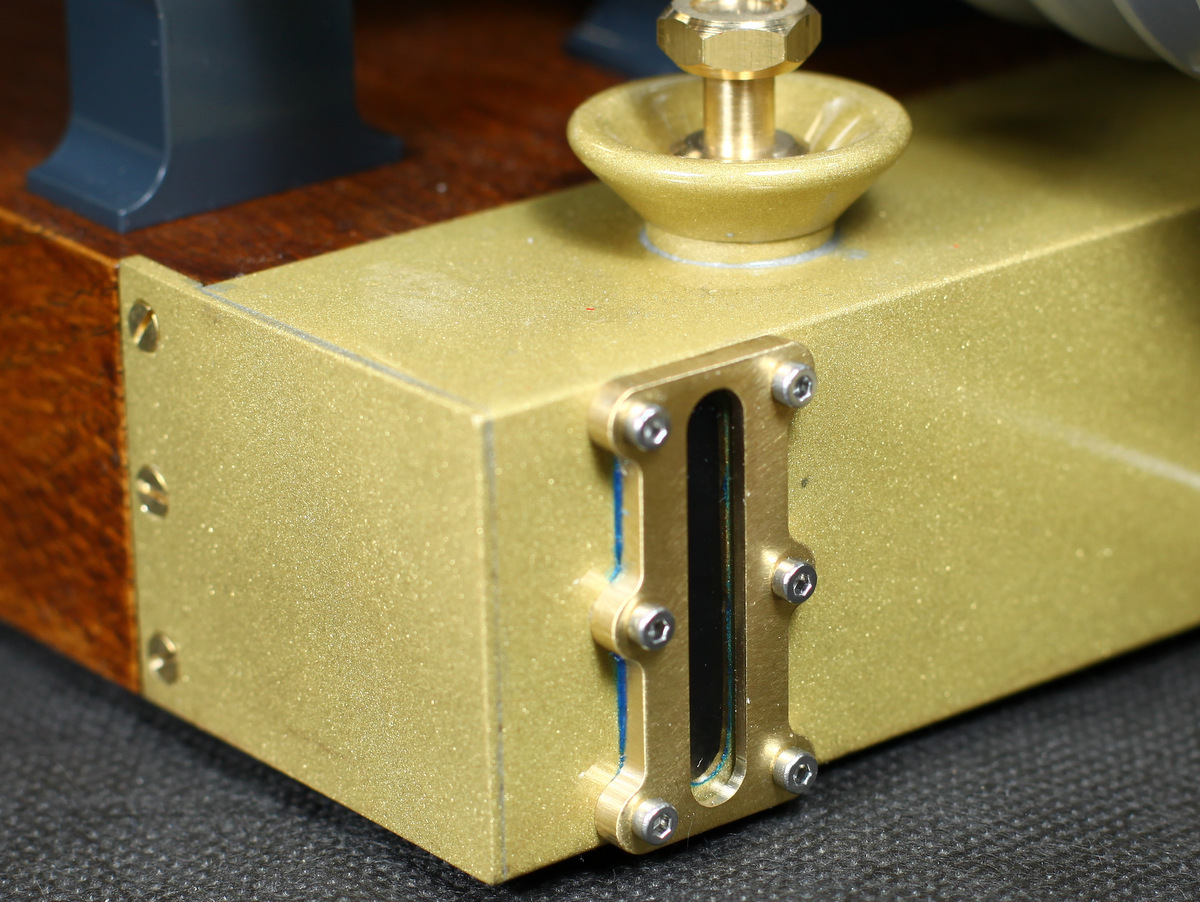

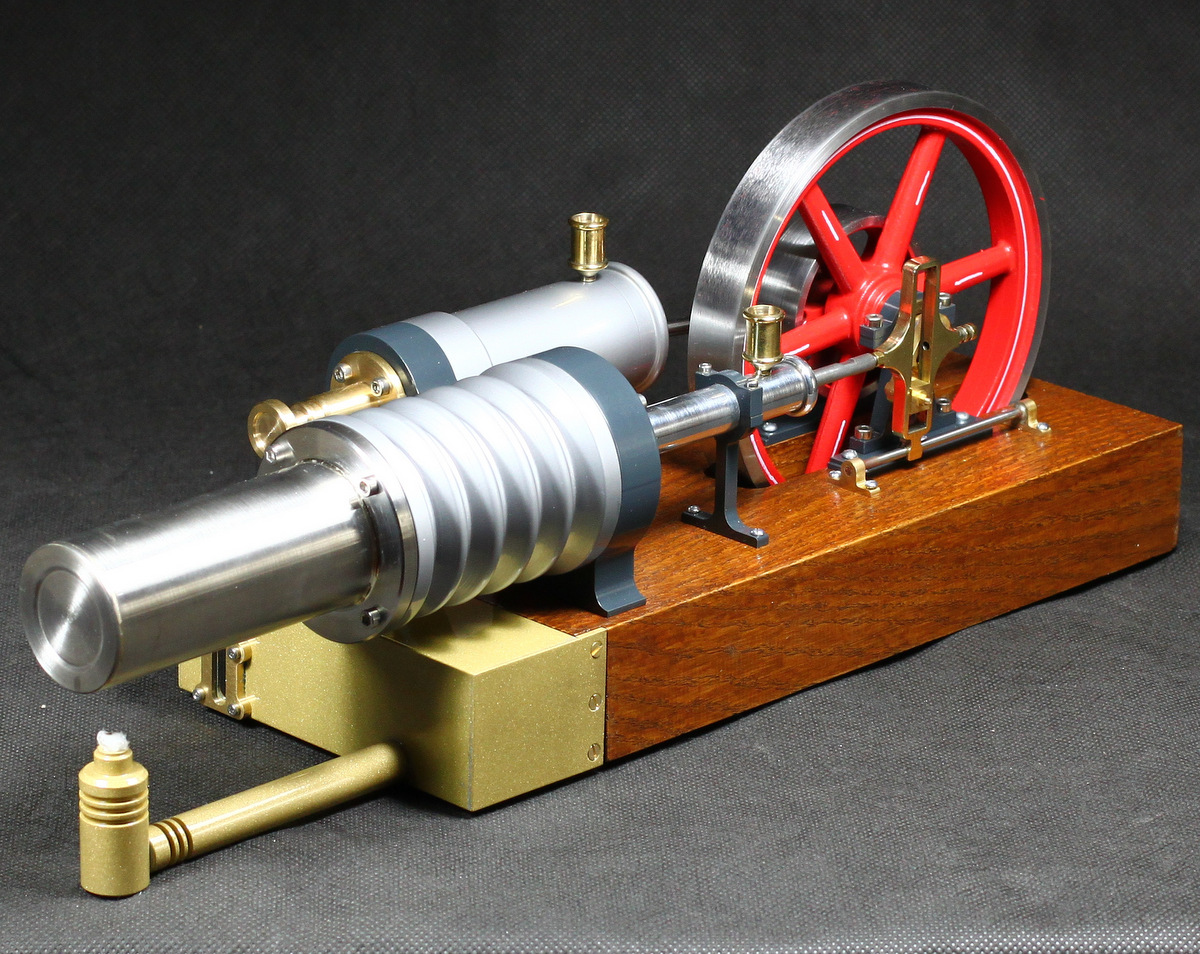

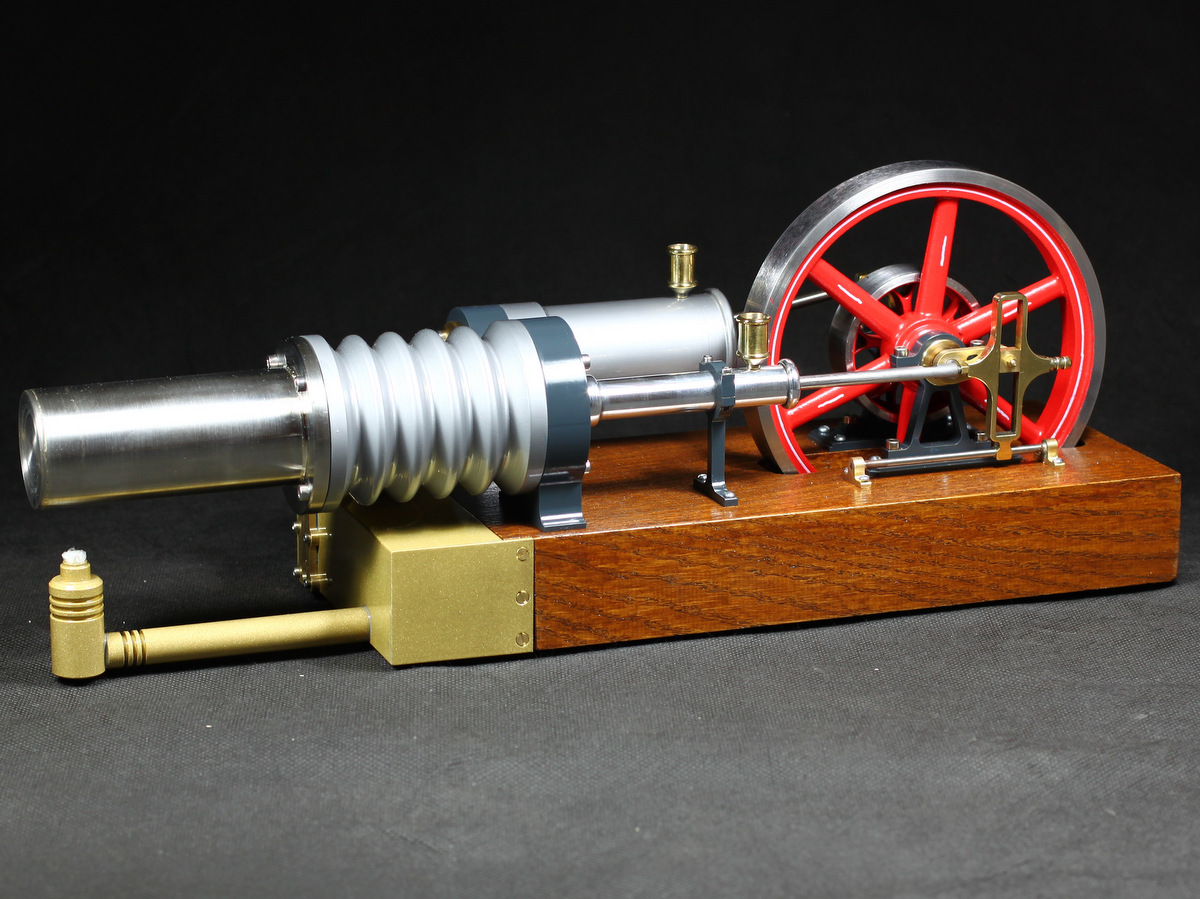

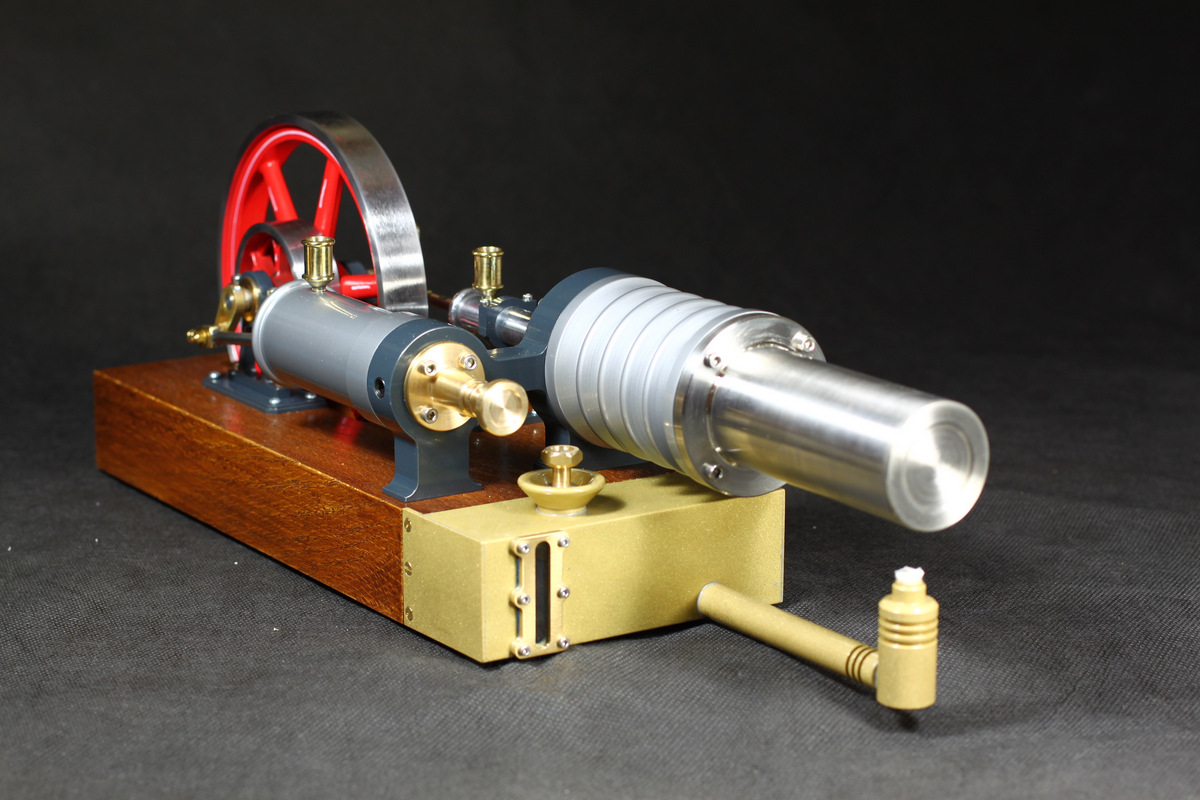

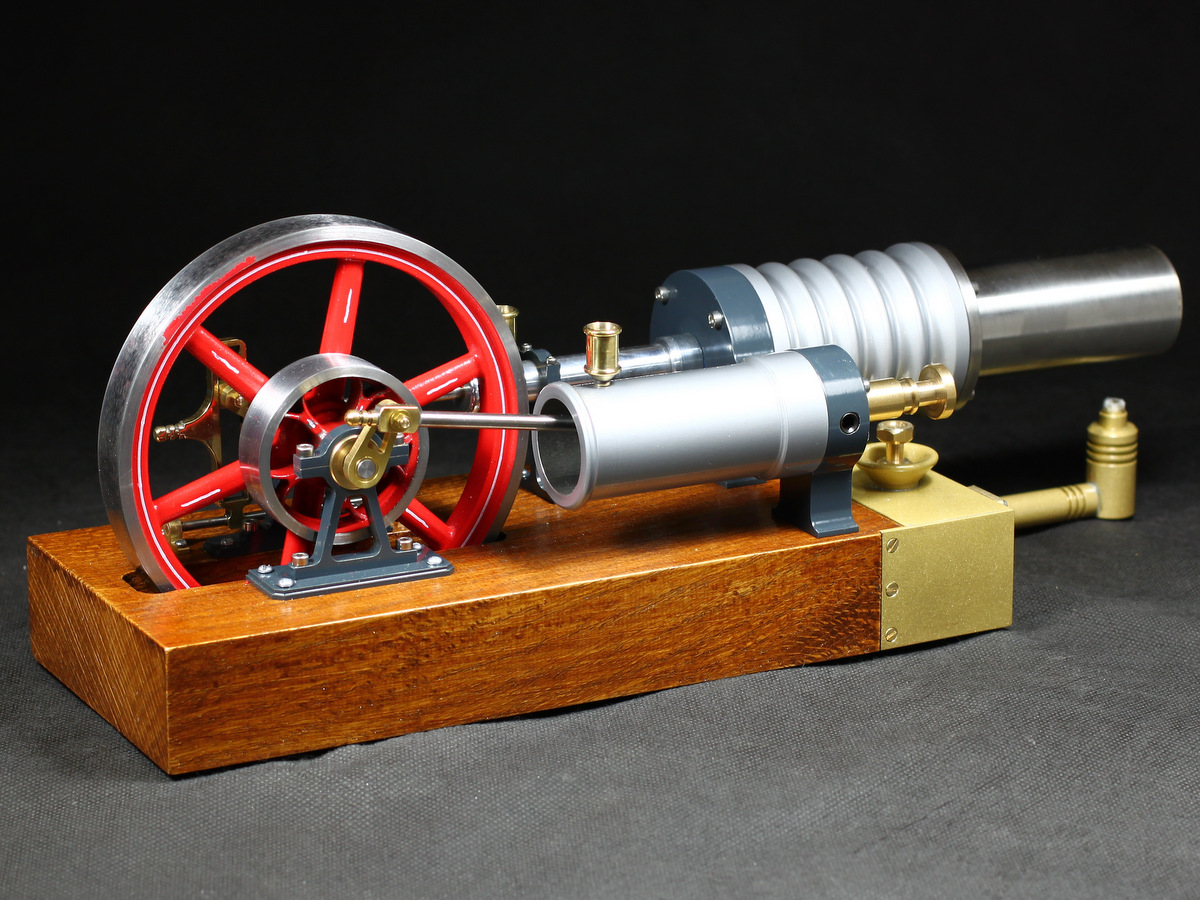

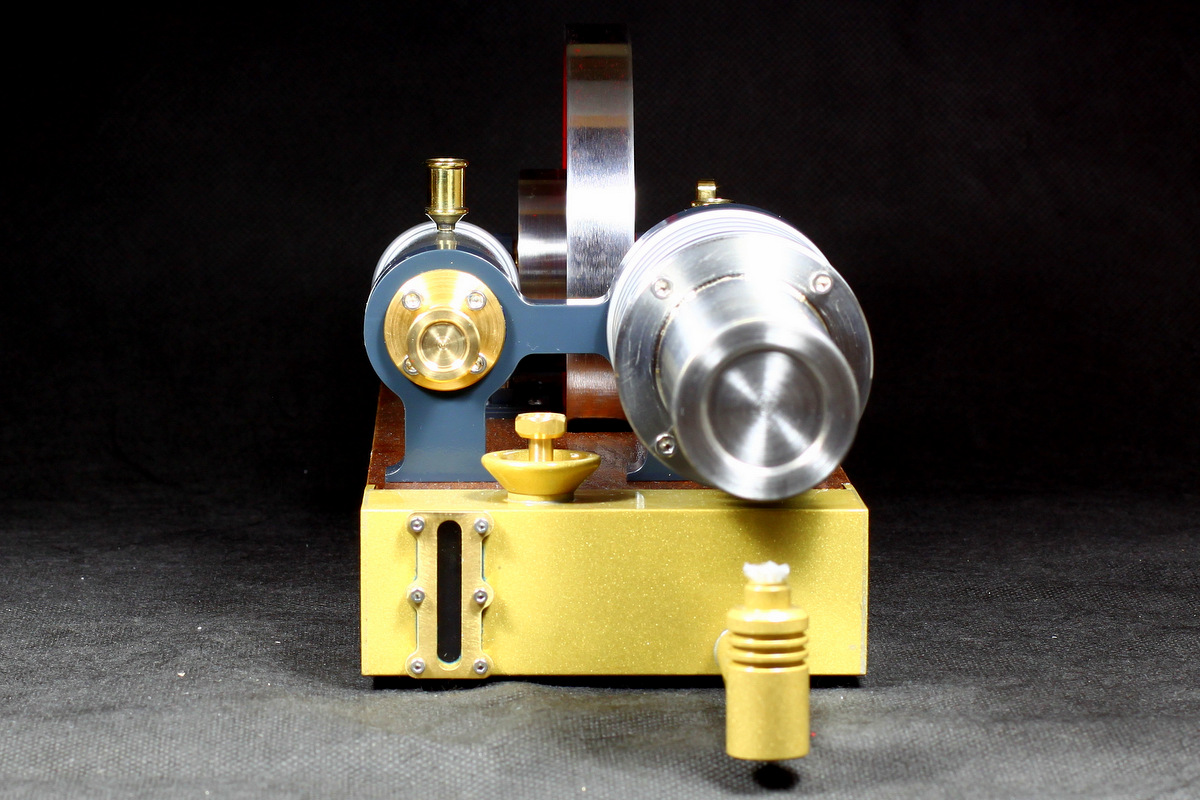

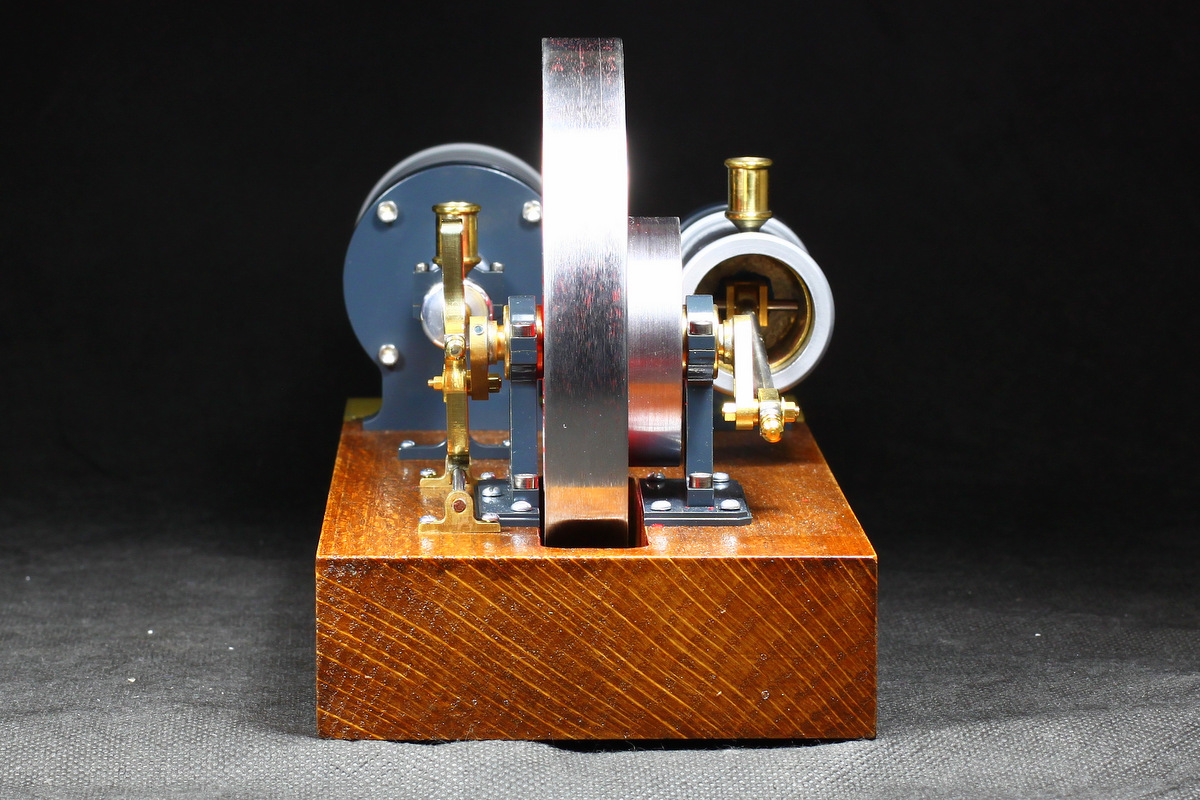

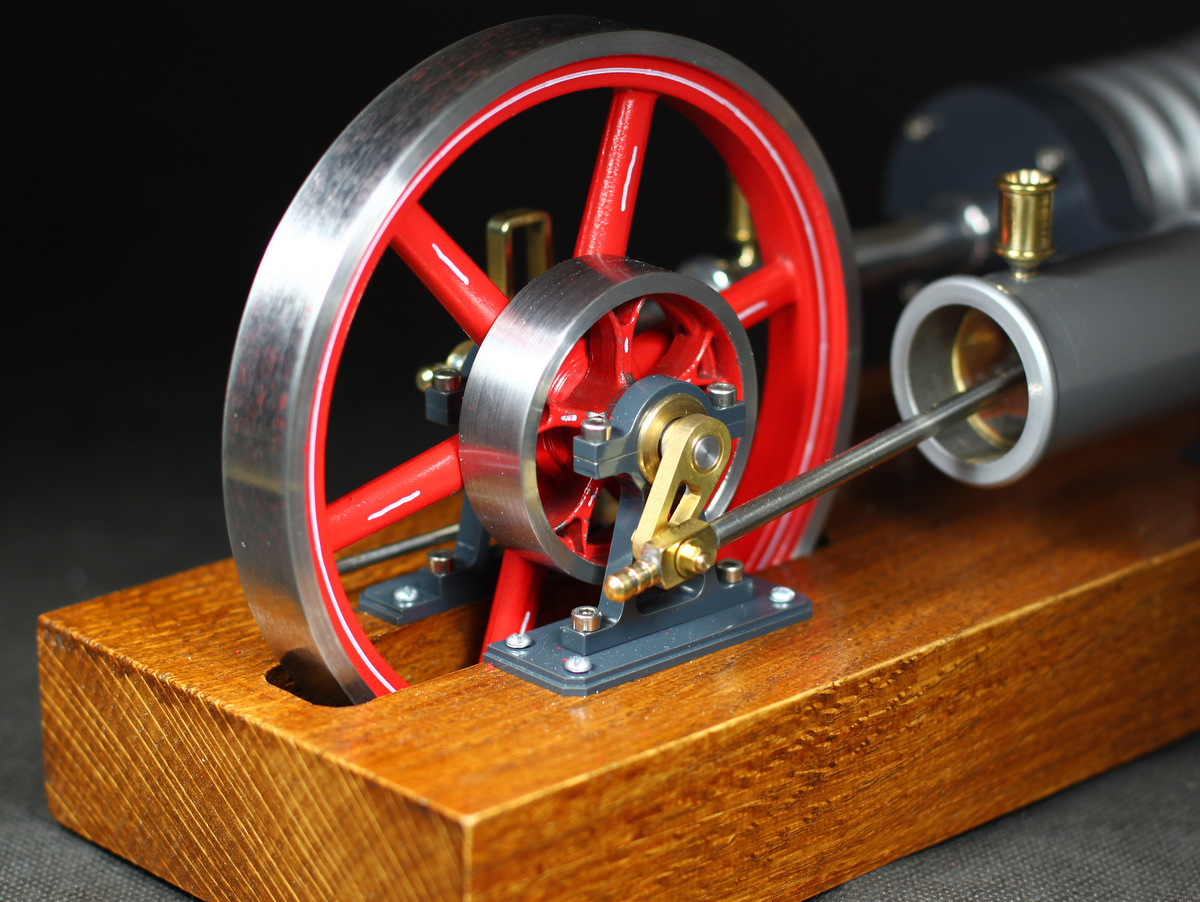

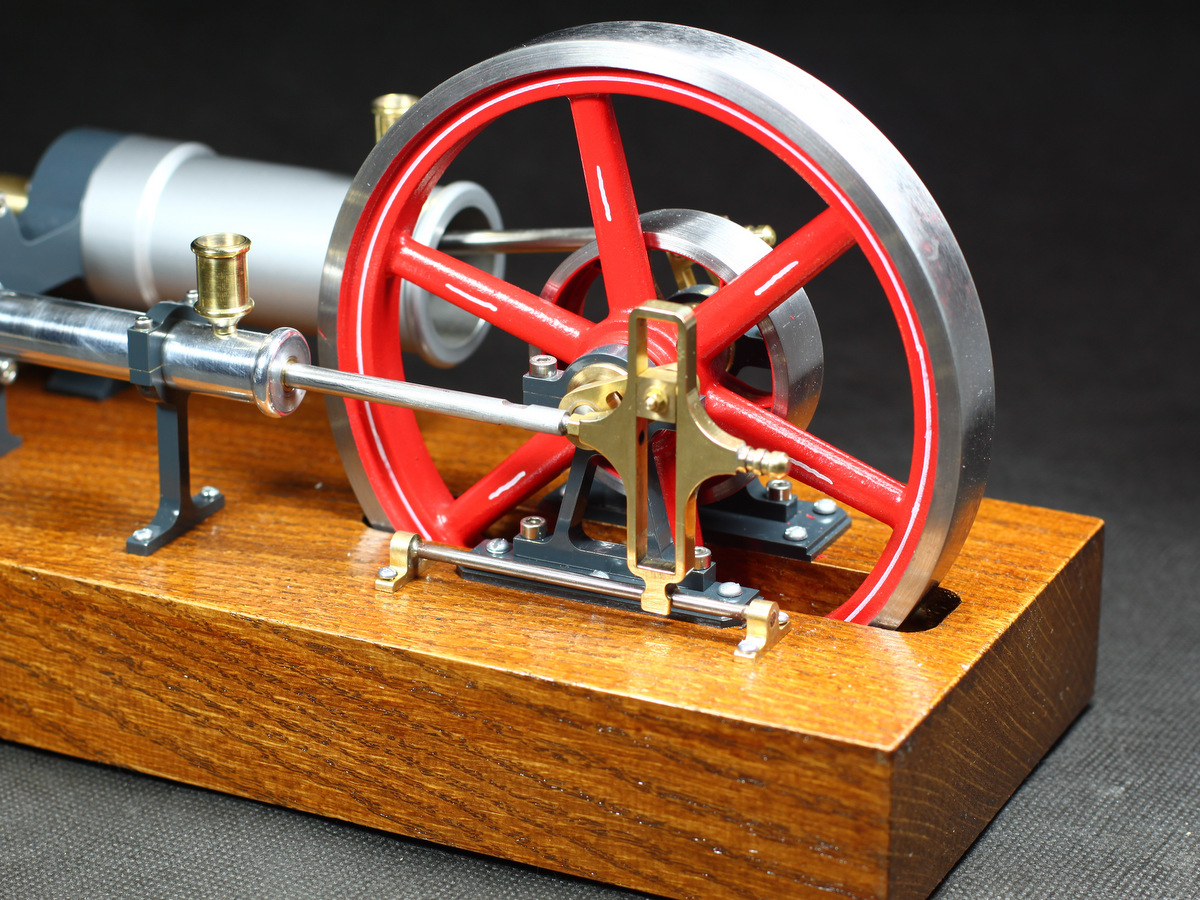

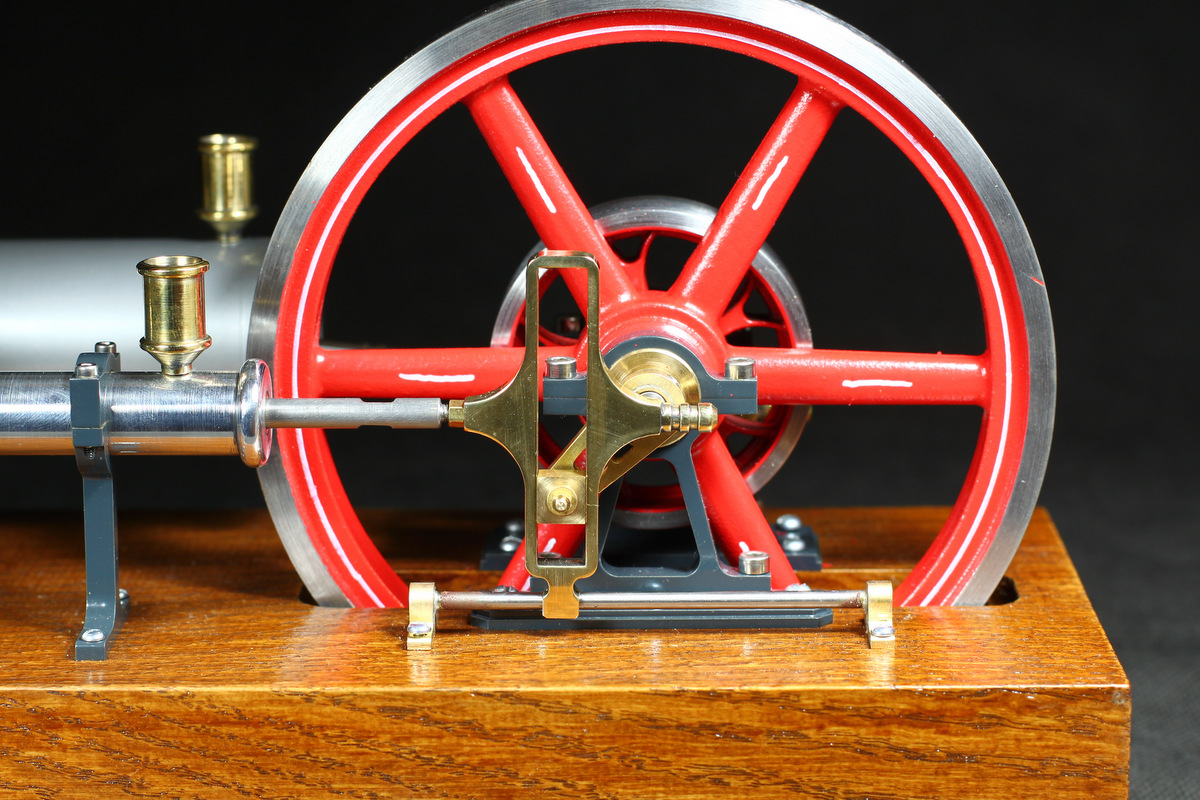

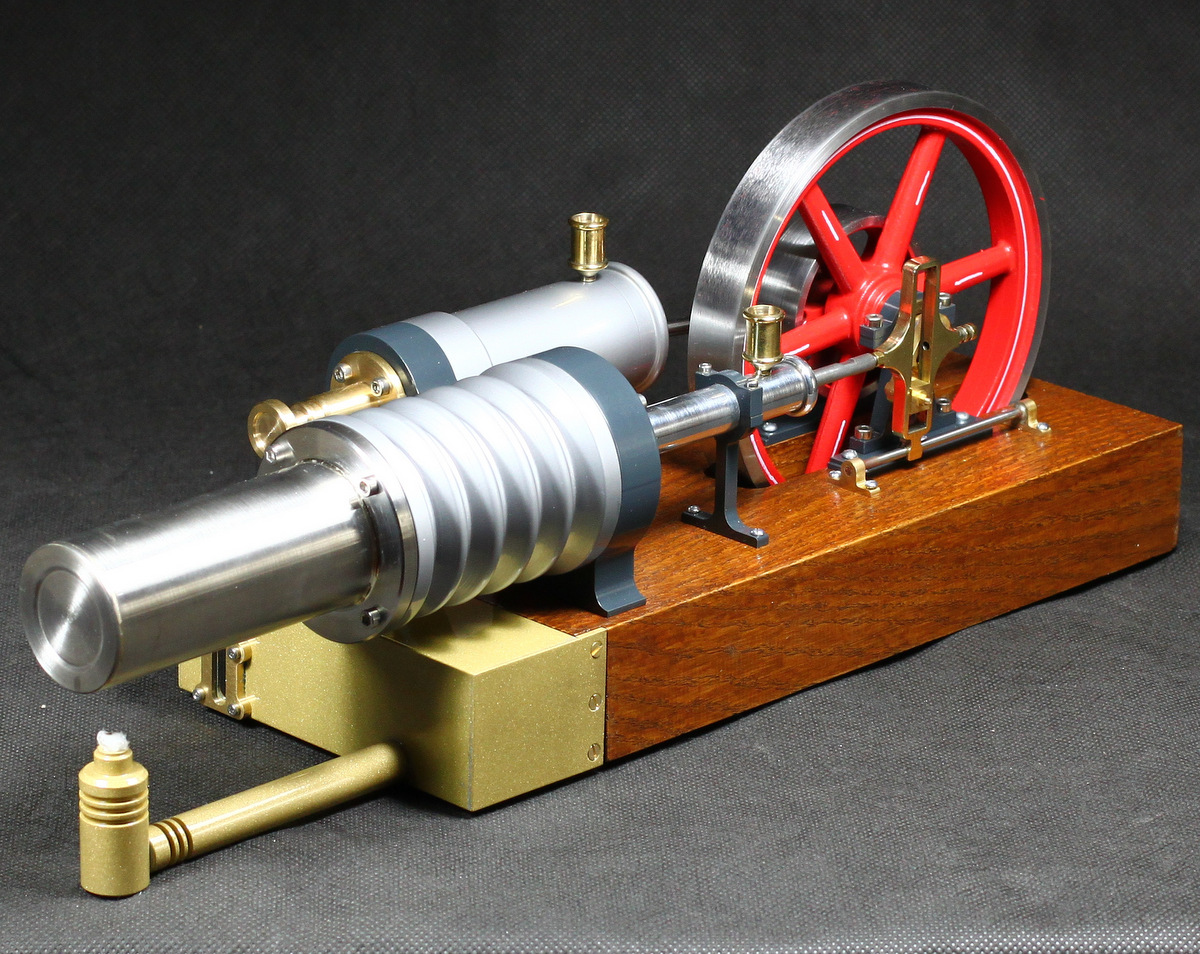

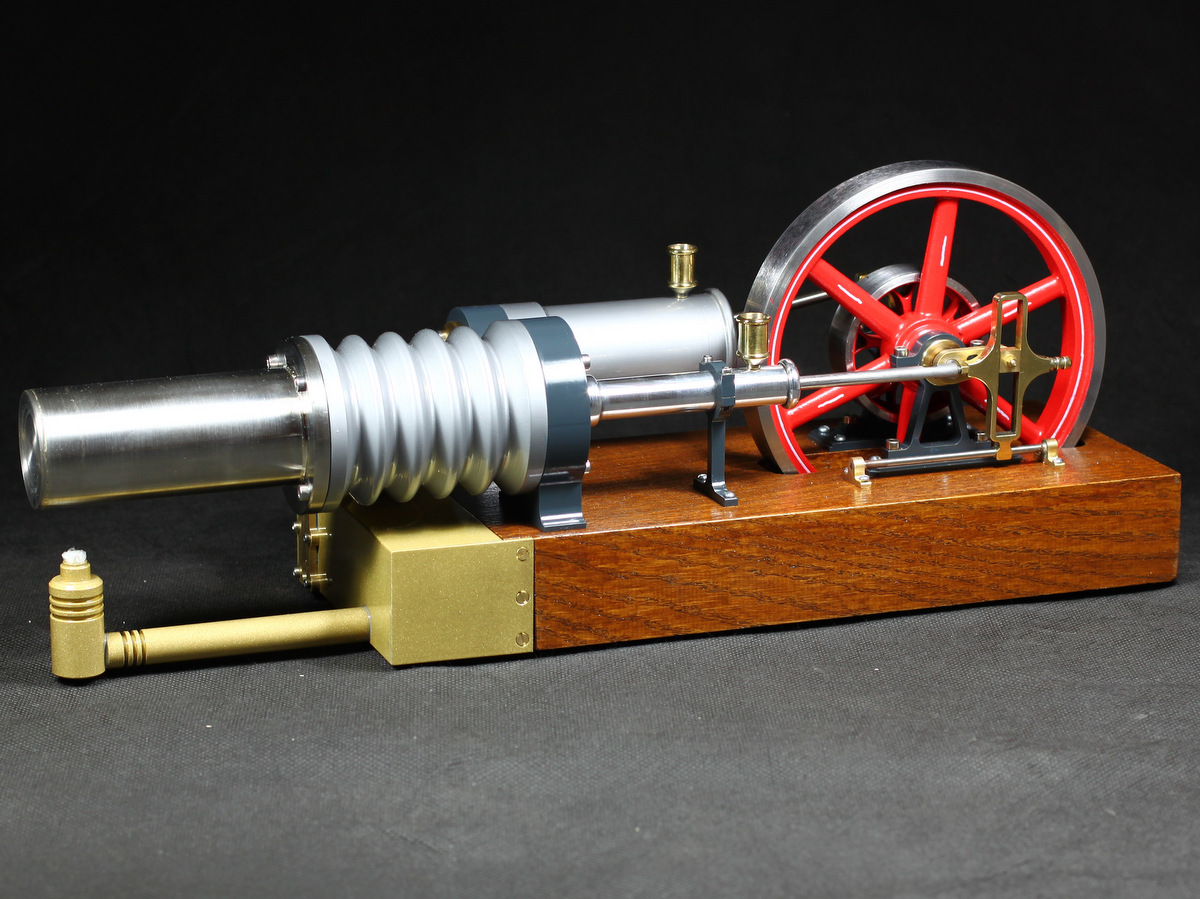

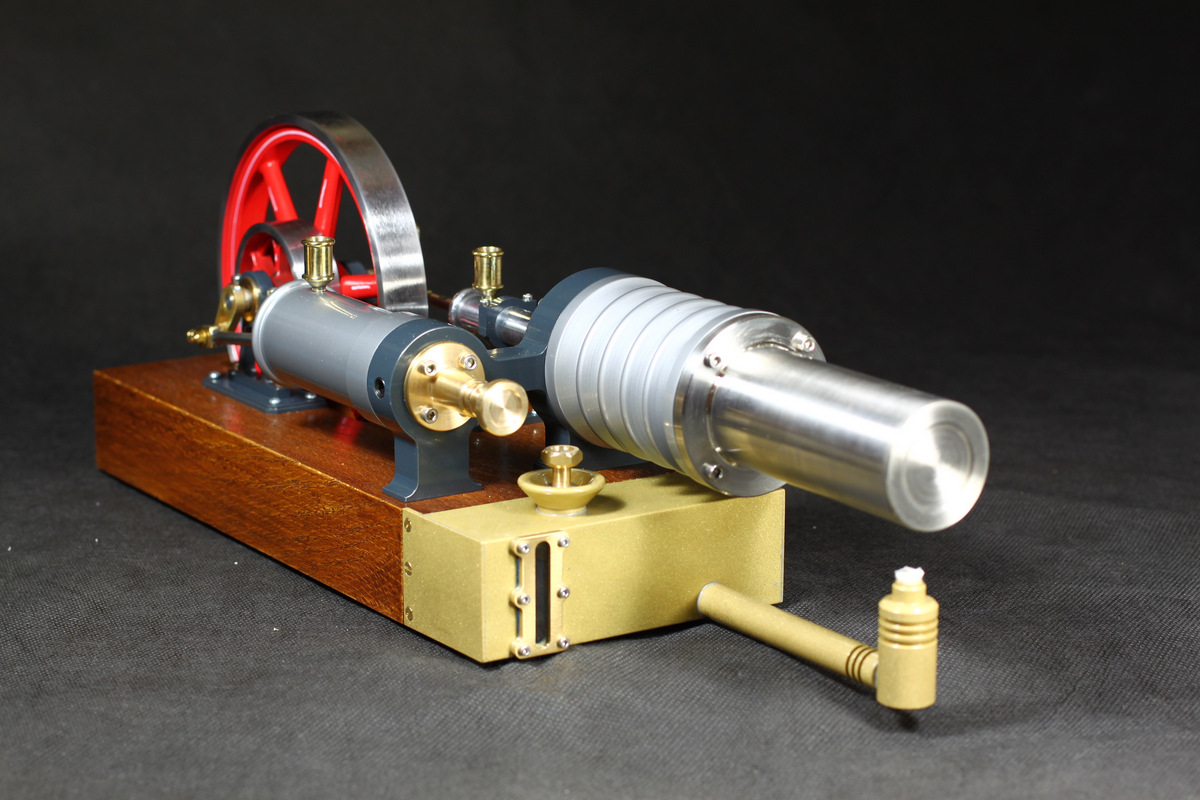

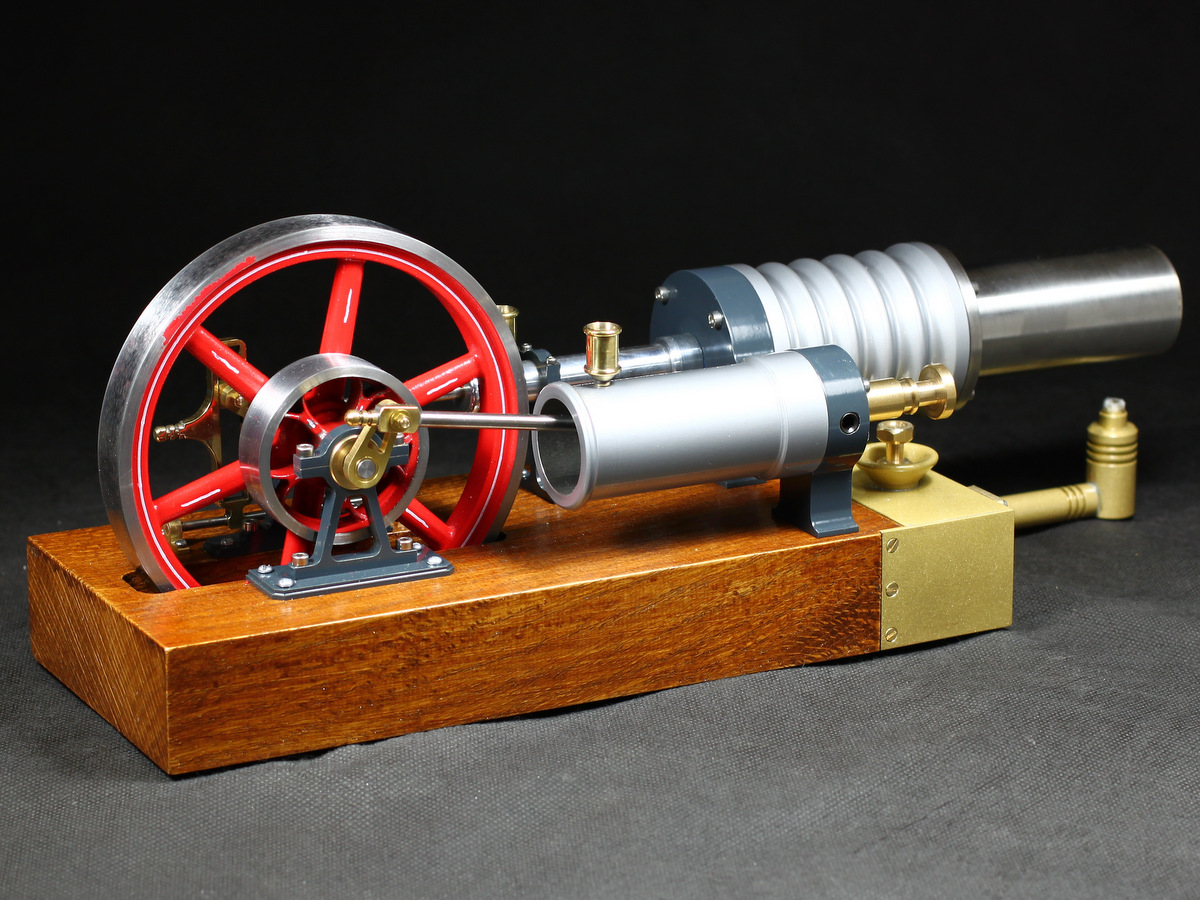

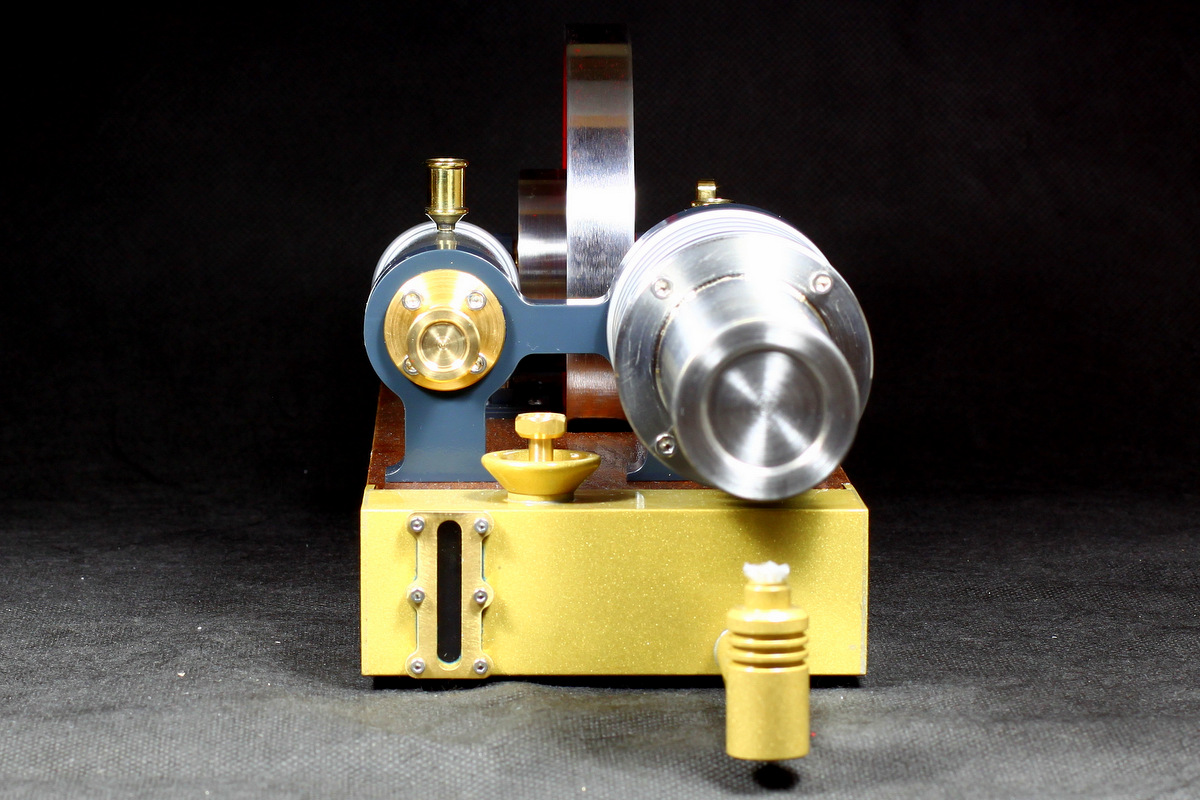

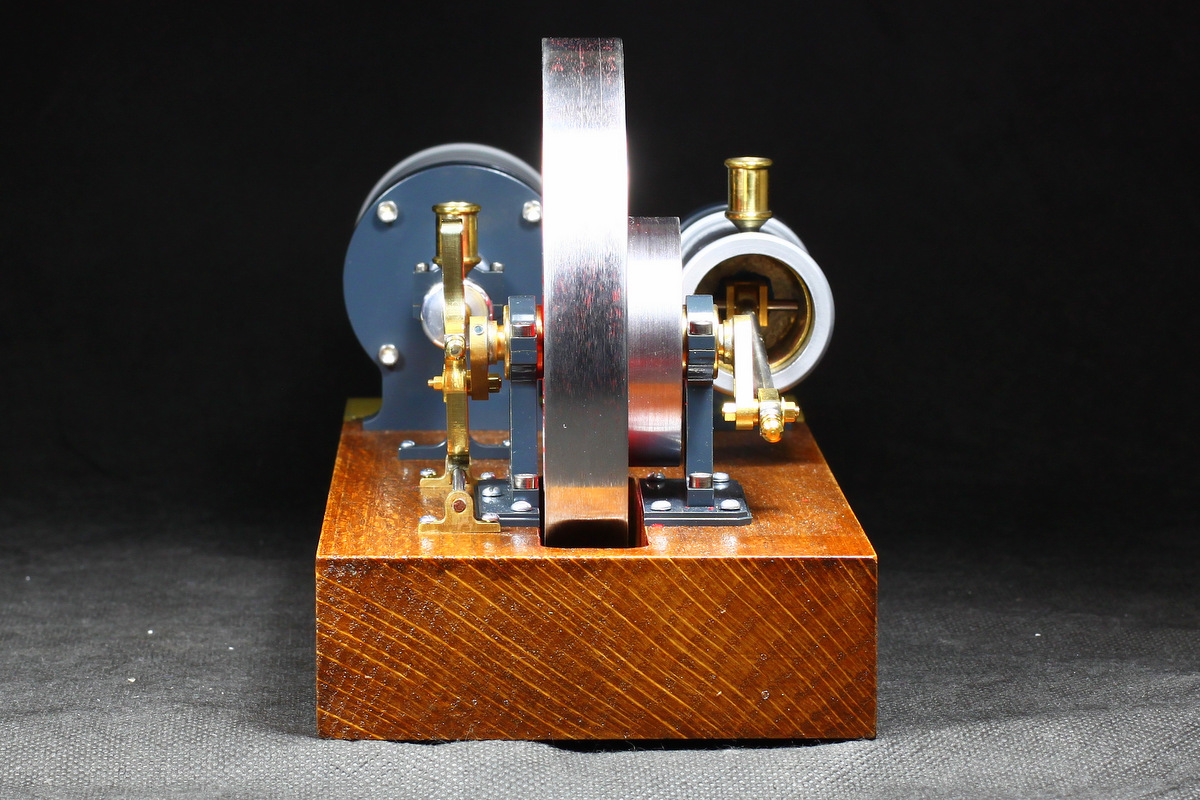

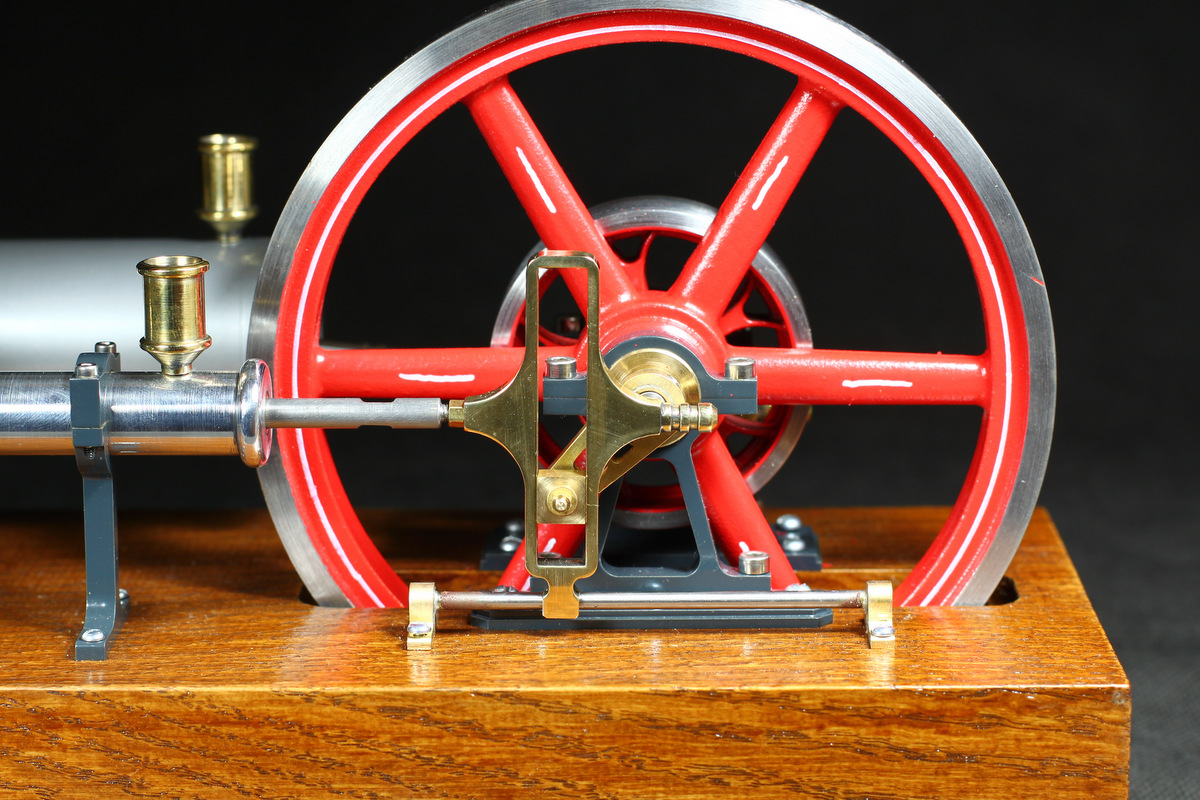

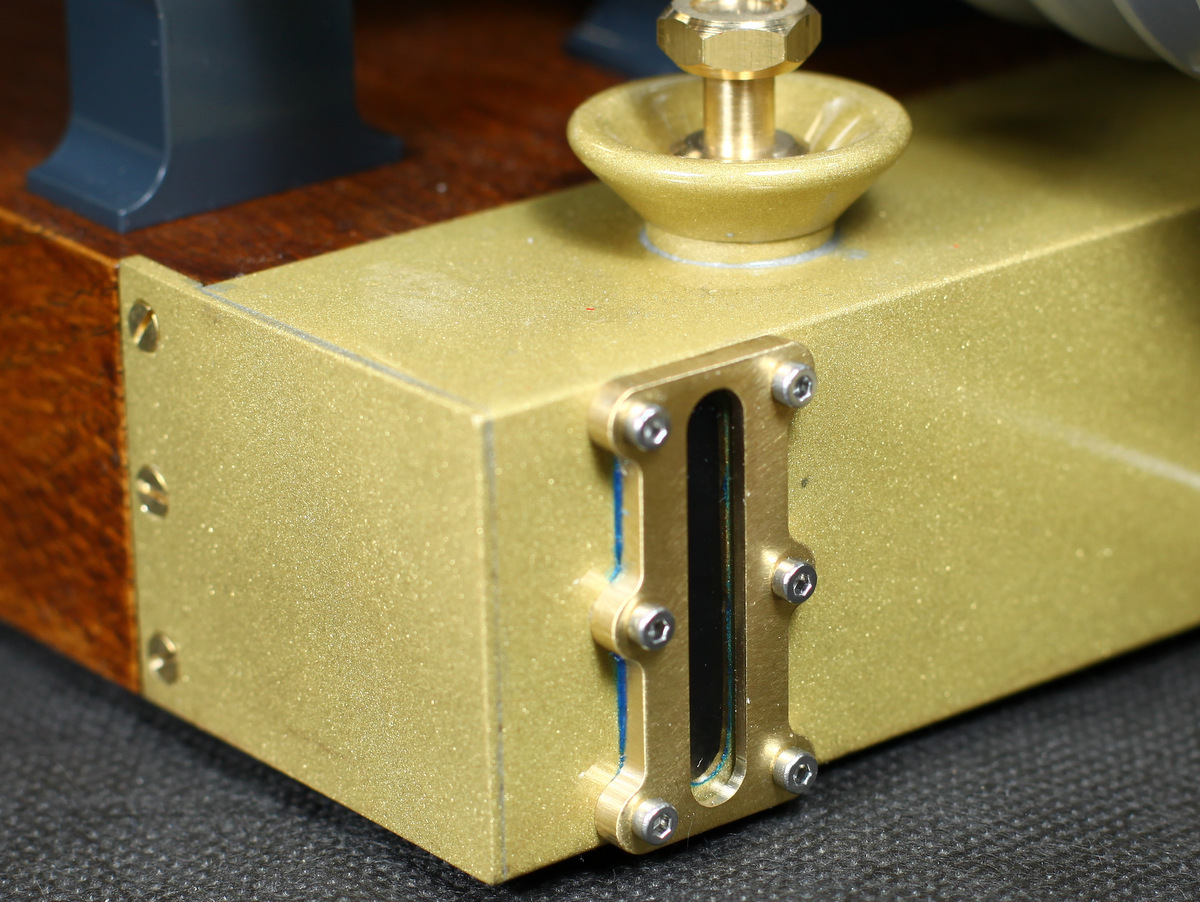

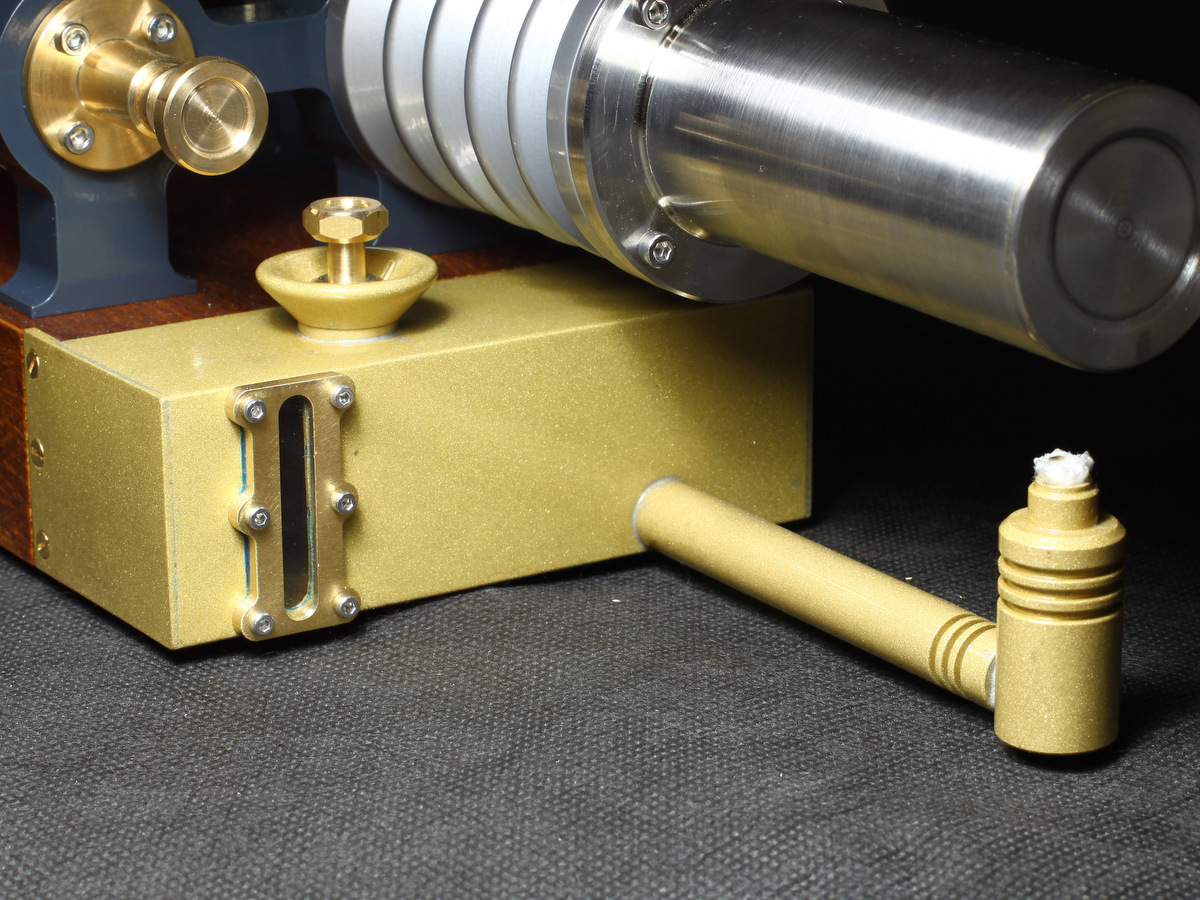

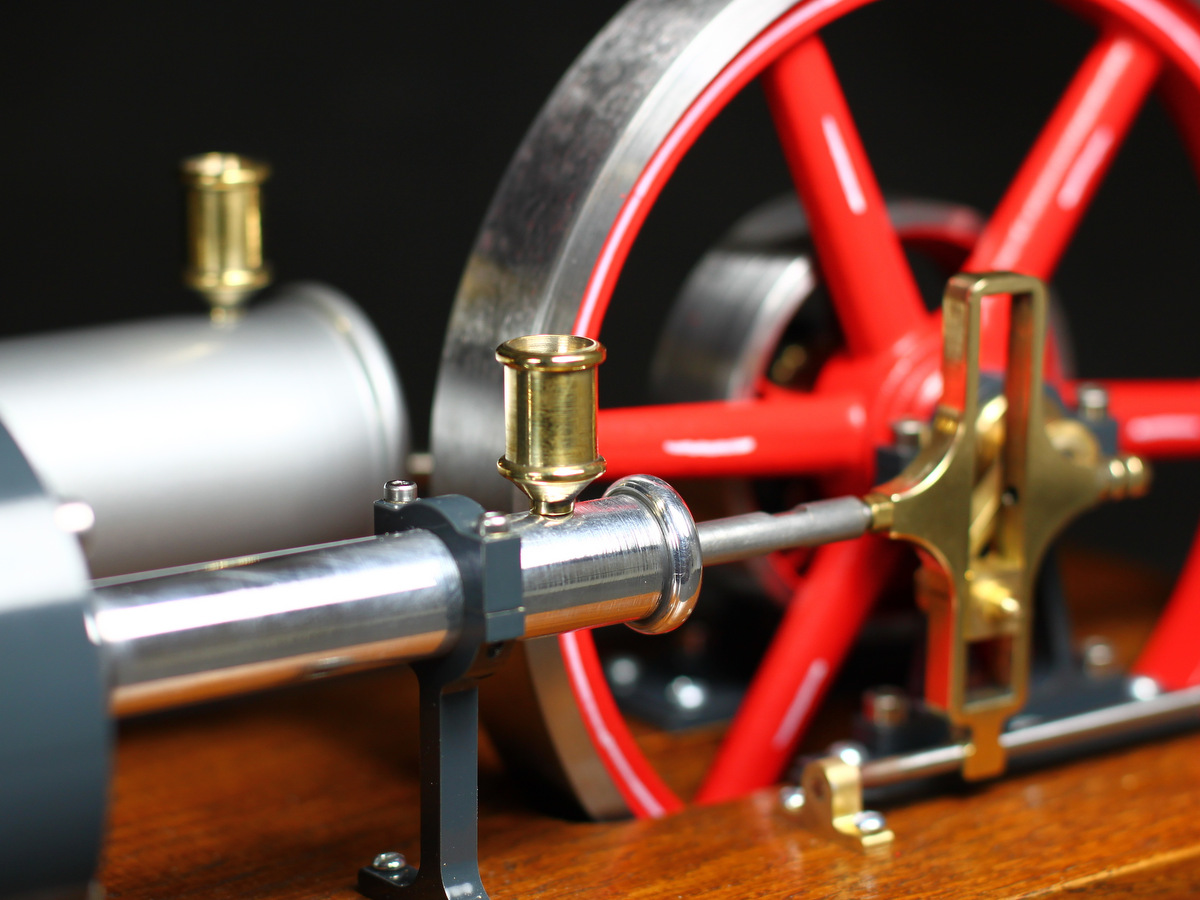

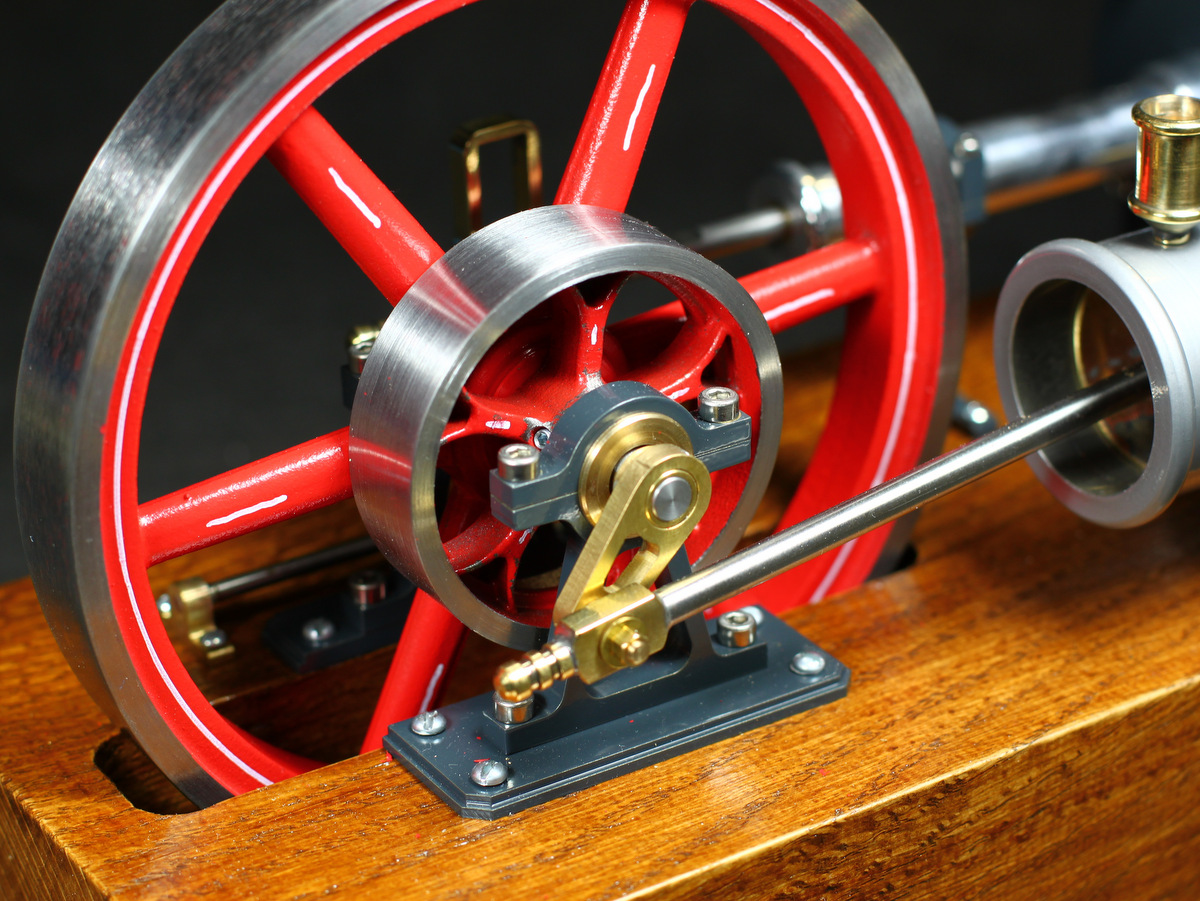

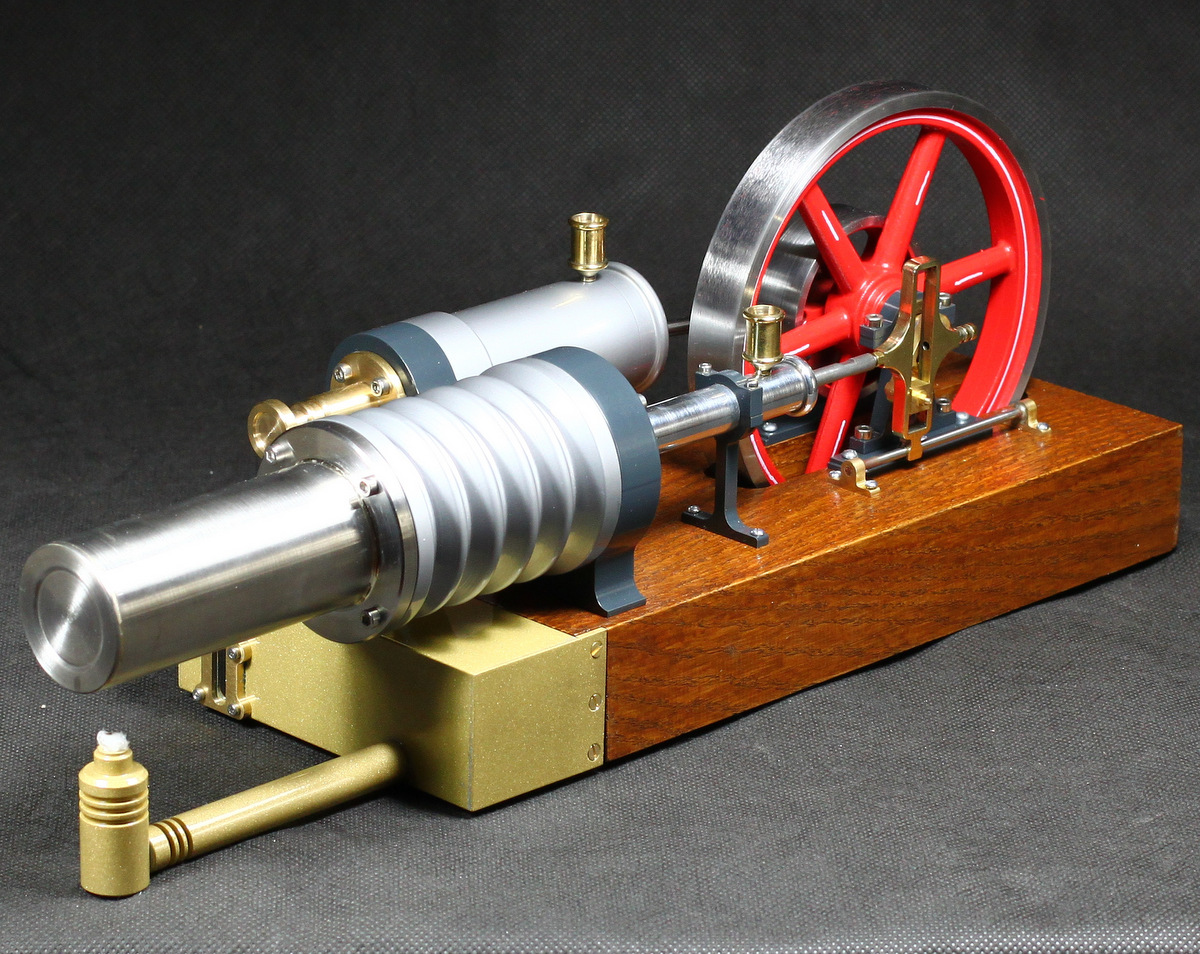

Stirling engine The big Laura

The model

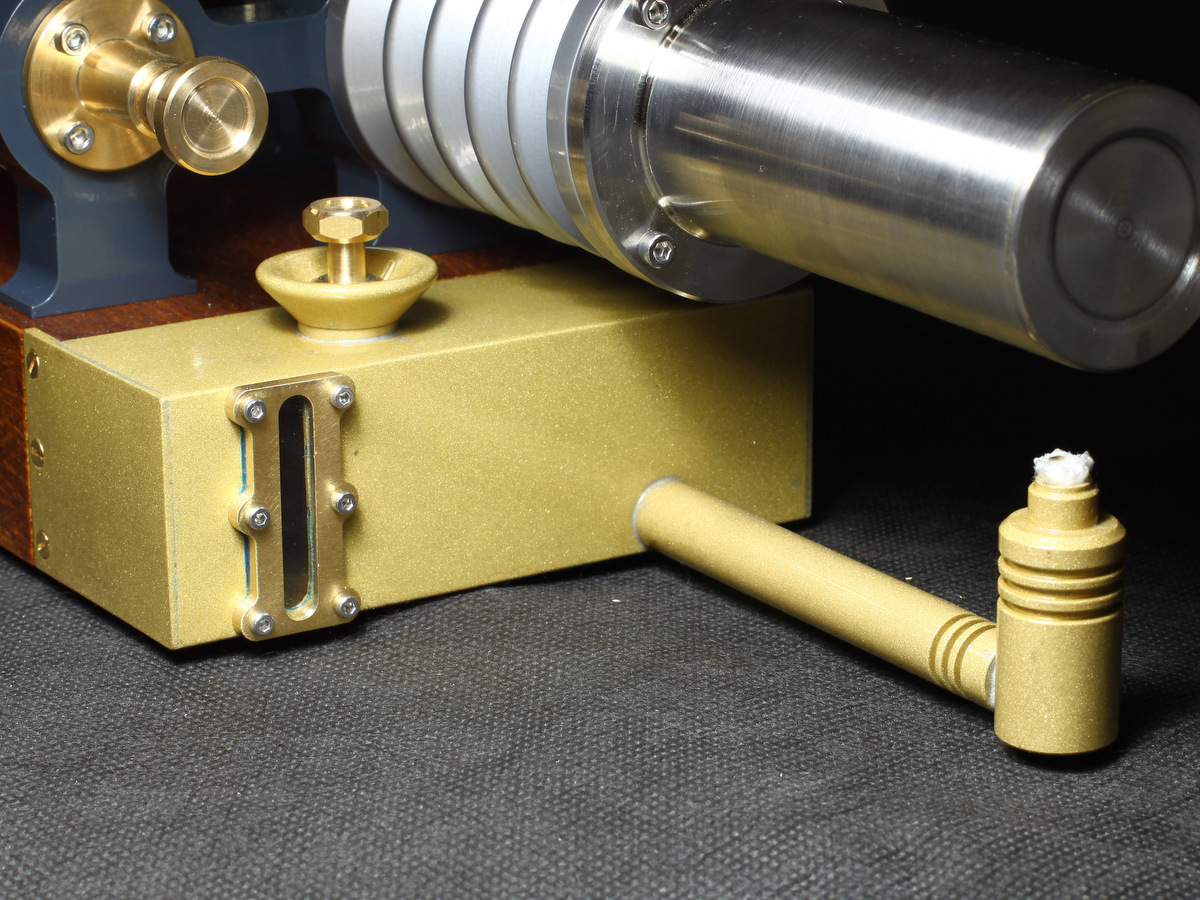

Dimensions of the model Stirling engine

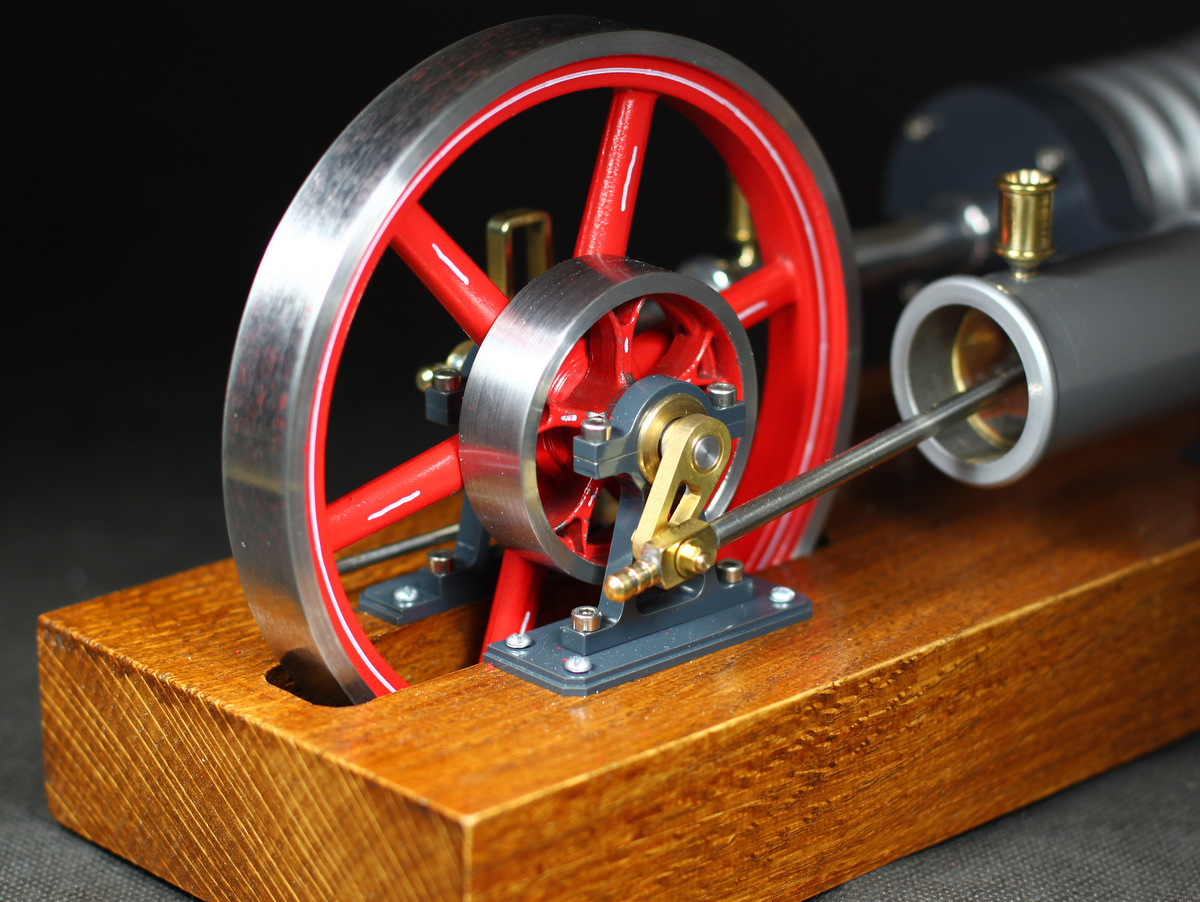

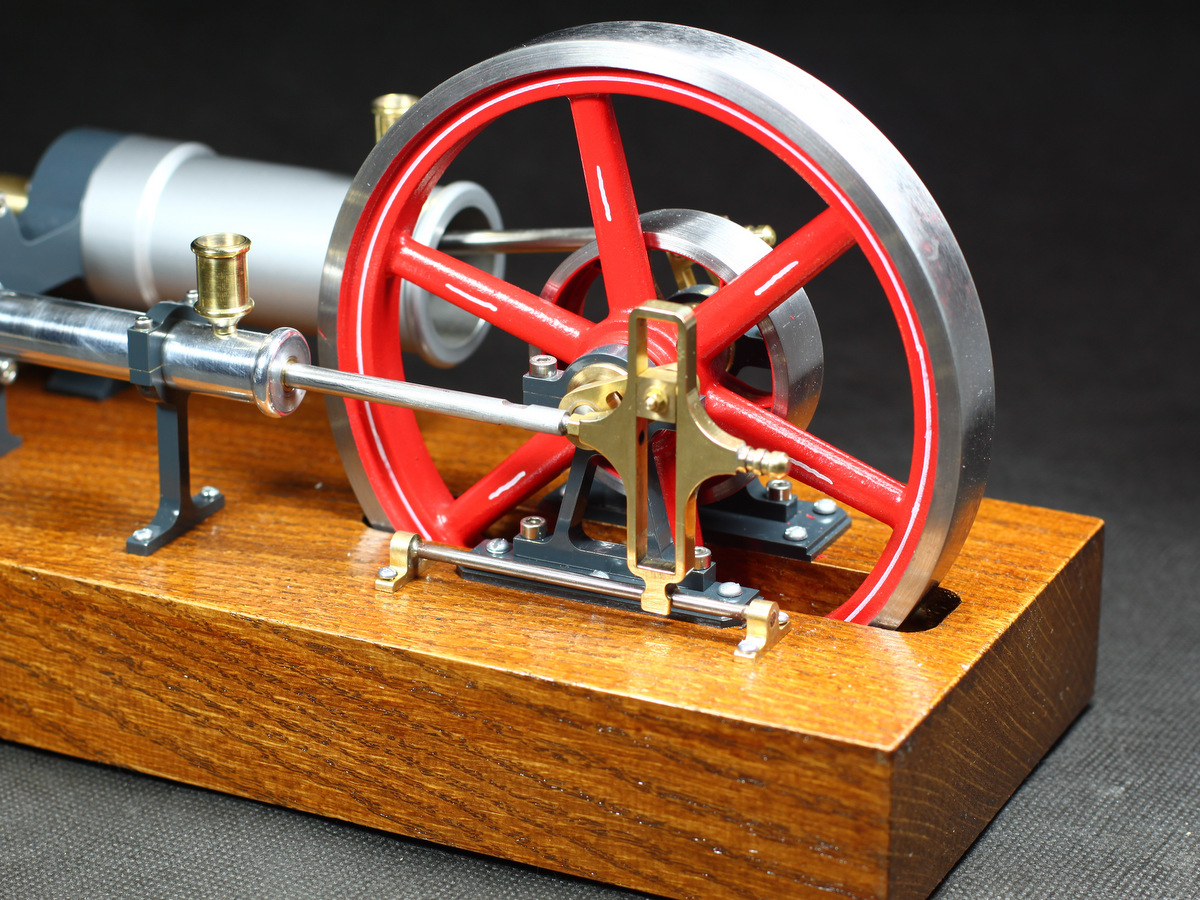

- Base plate: 255mm x 120mm

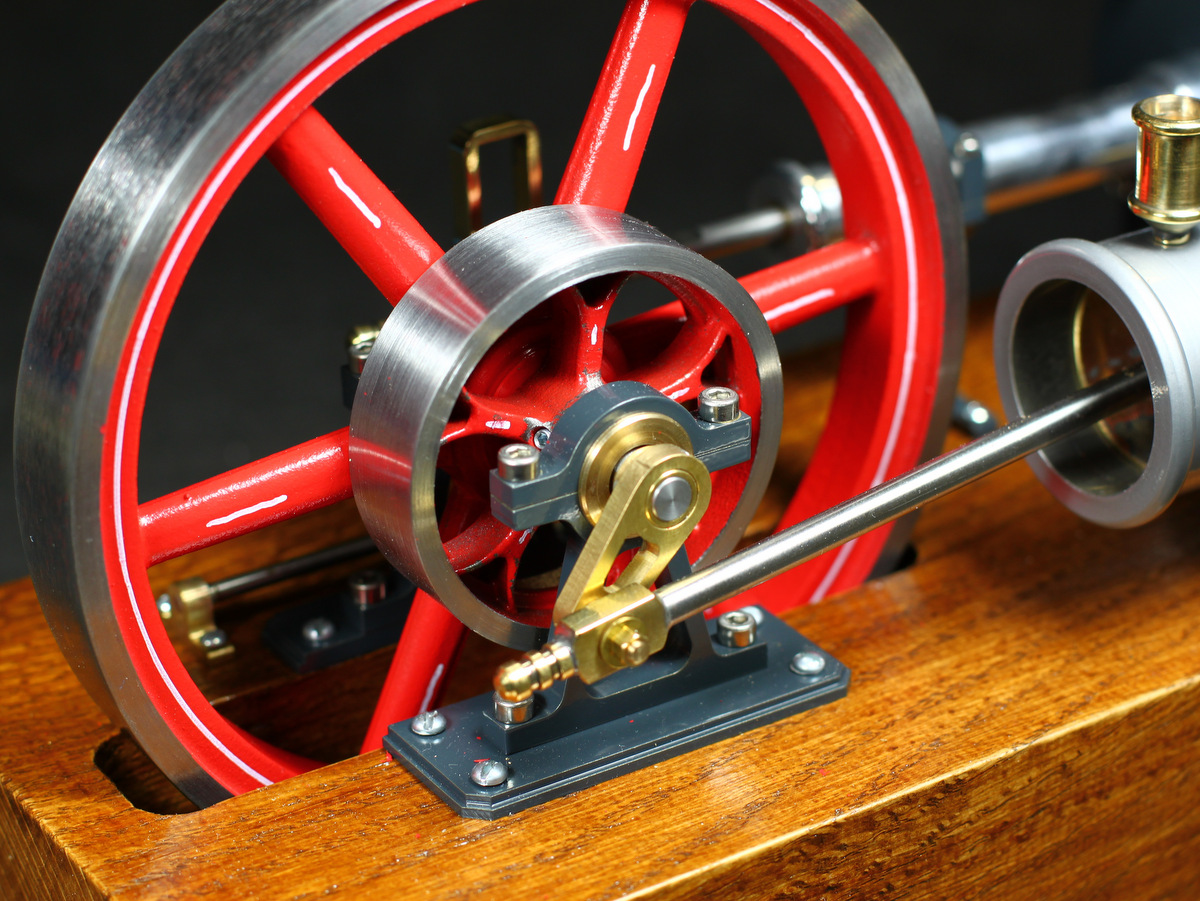

- Flywheel: 140mm

- Pulley: 56mm < /li>

- Total height: 120mm

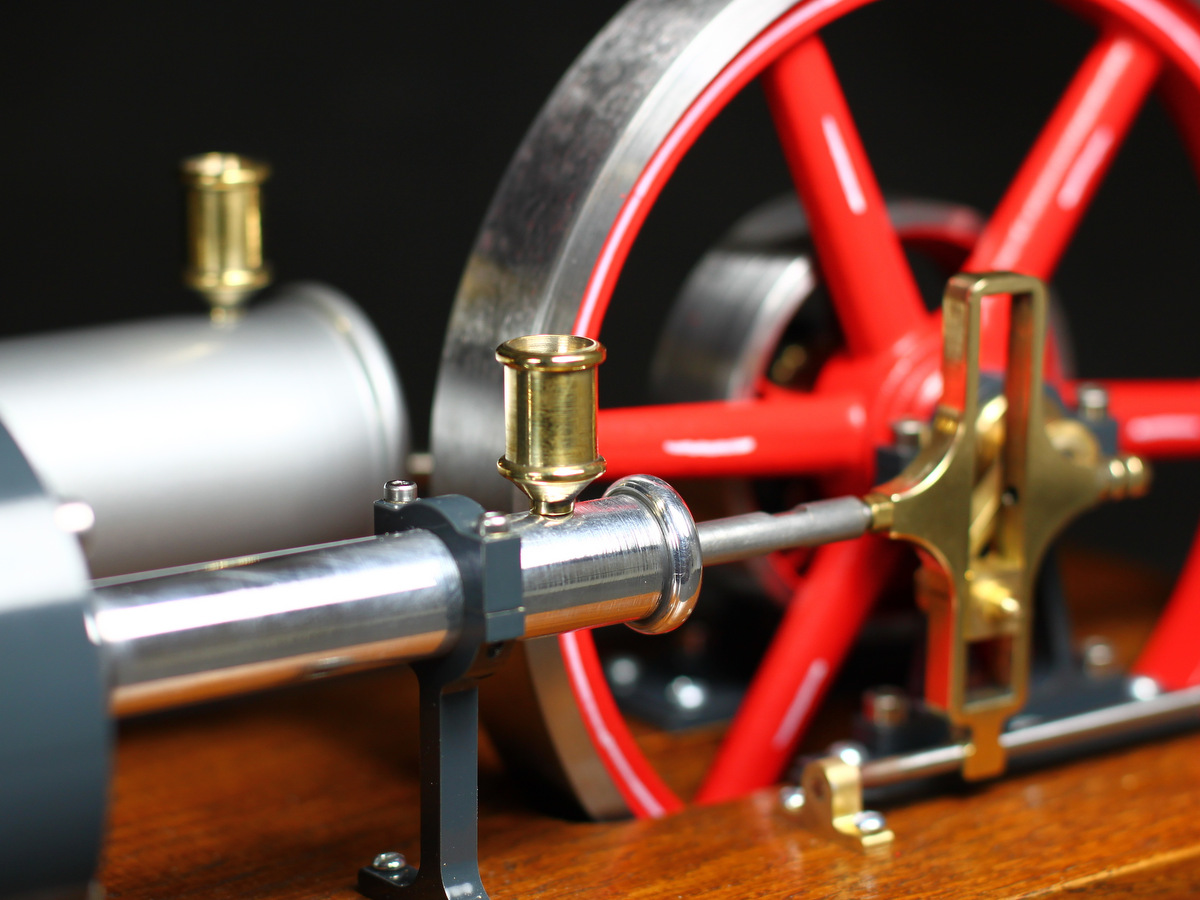

- Working piston: 30mm

- Displacer piston: 35mm

- Overall length: 410mm

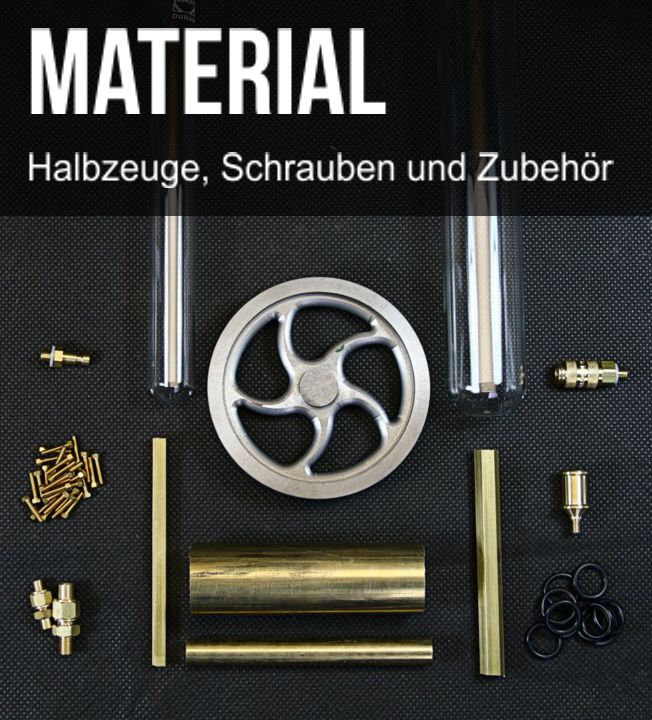

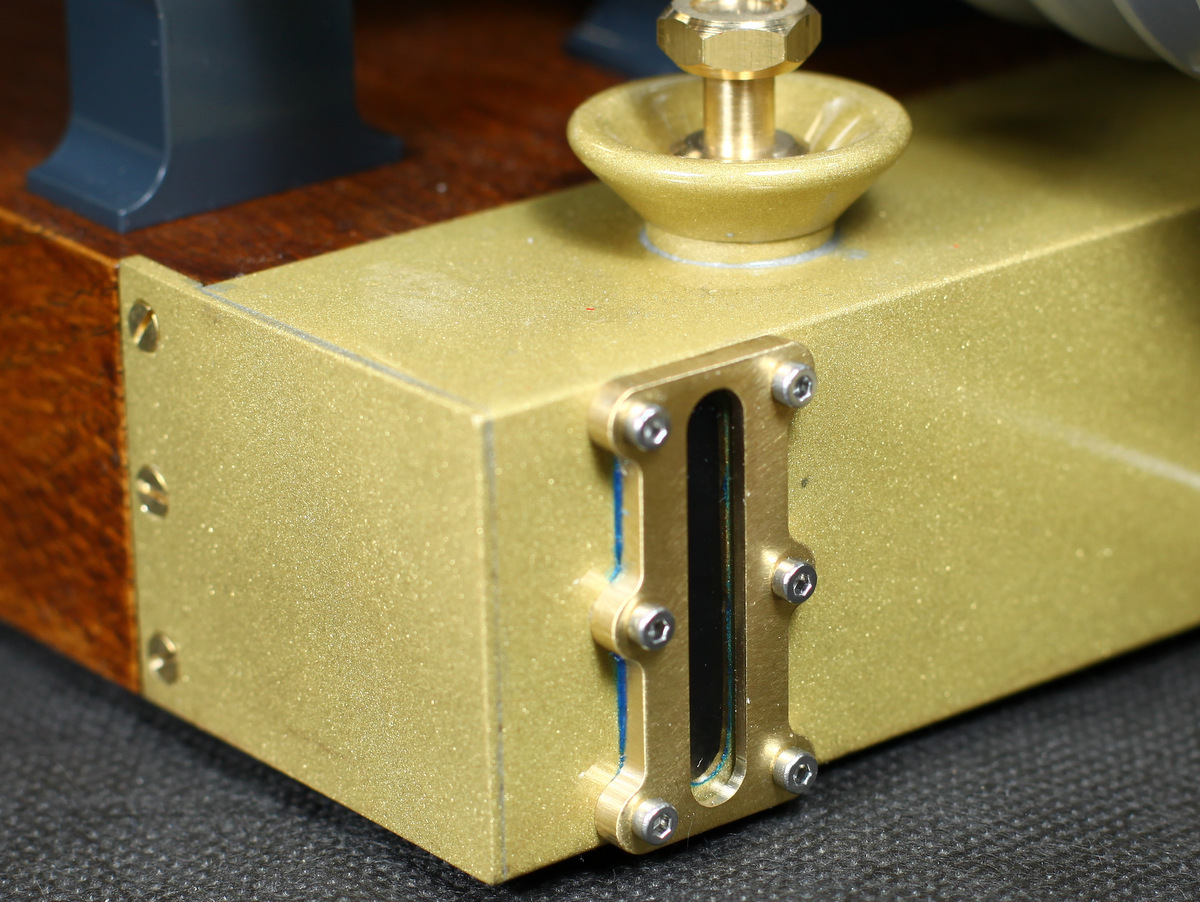

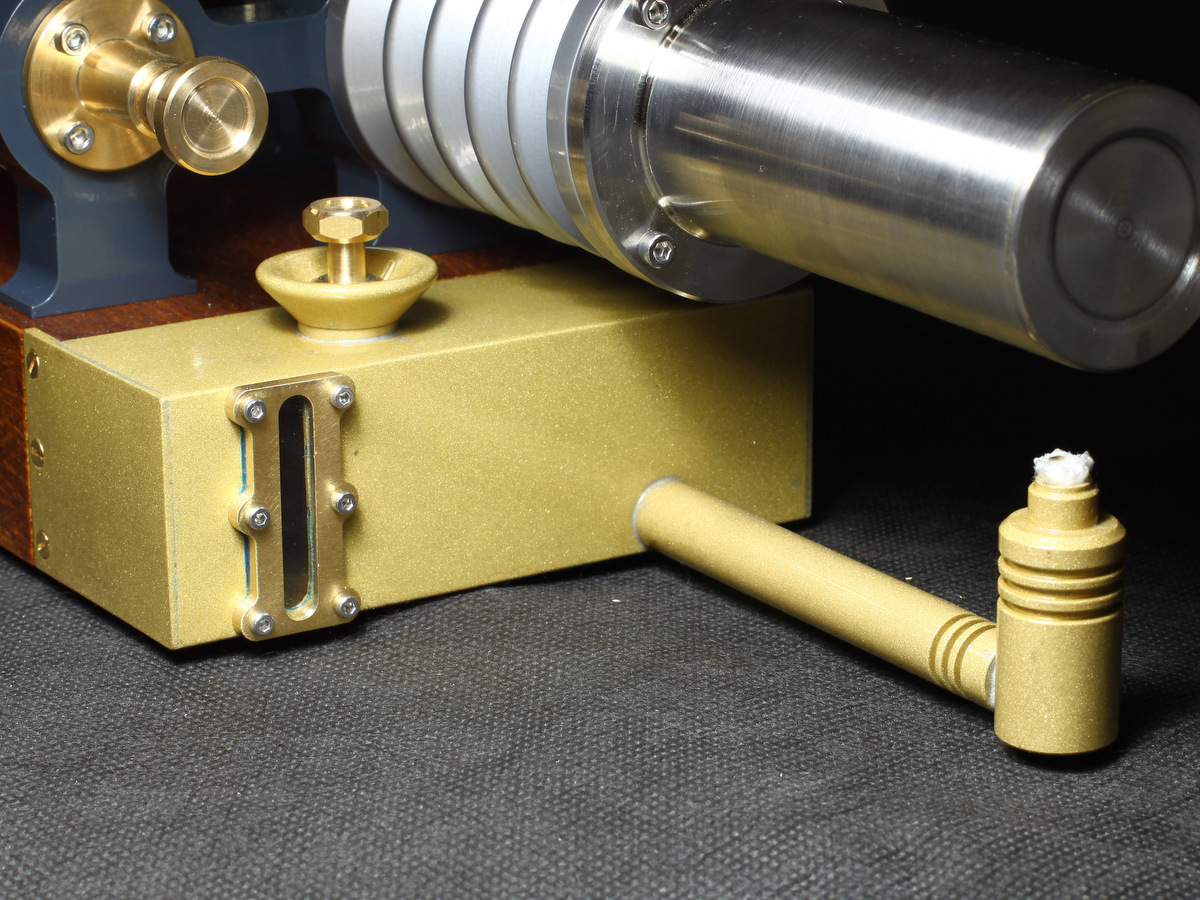

Included in the scope of delivery of the material kit Stirling engine "The Great Laura" are

- Milled wooden base plate Finished

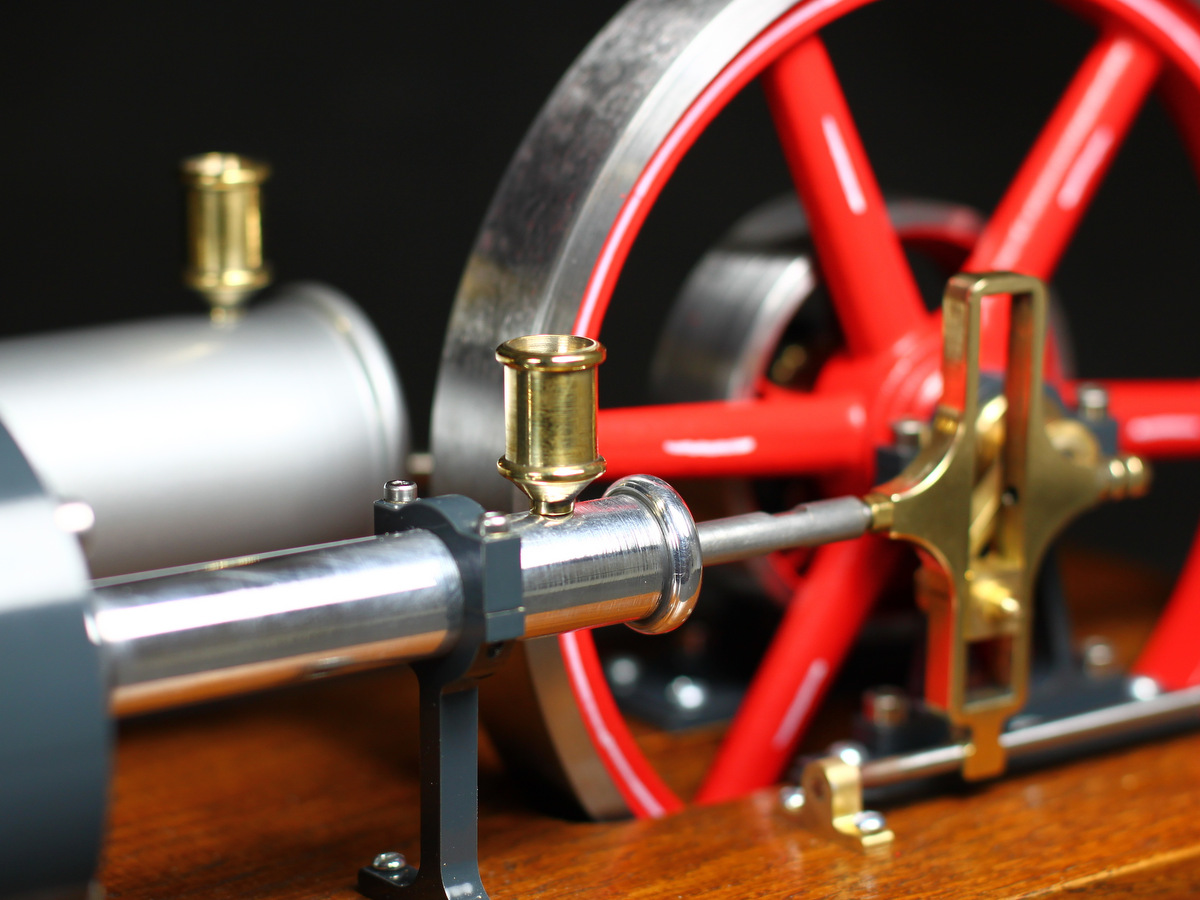

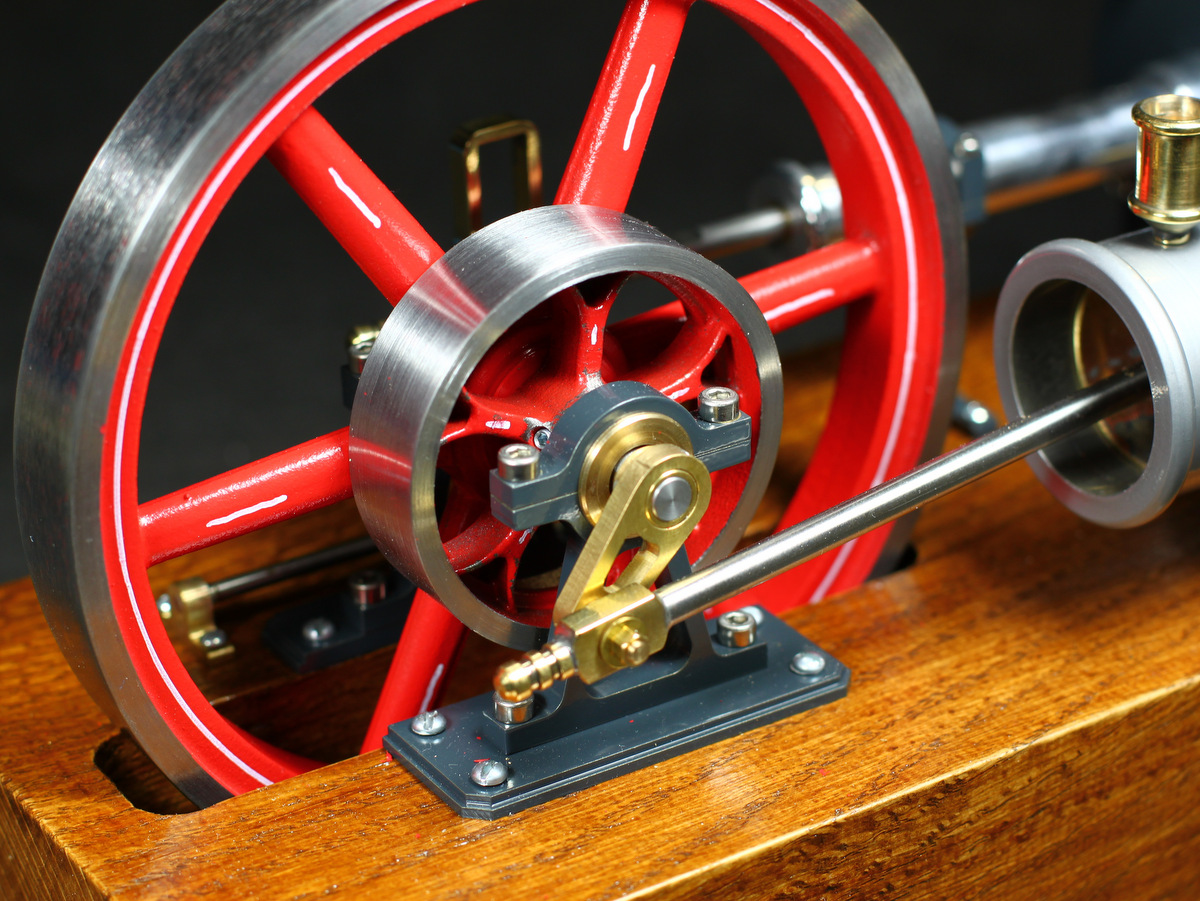

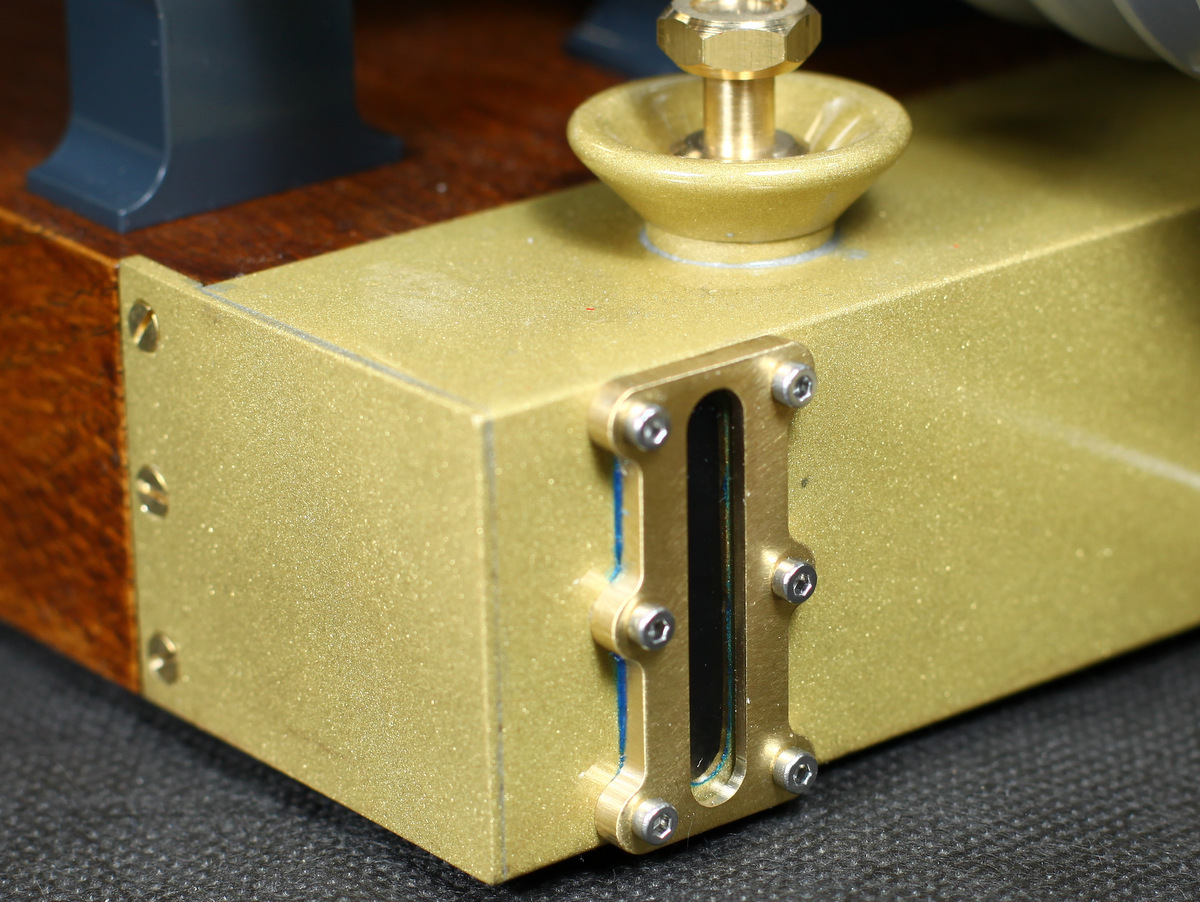

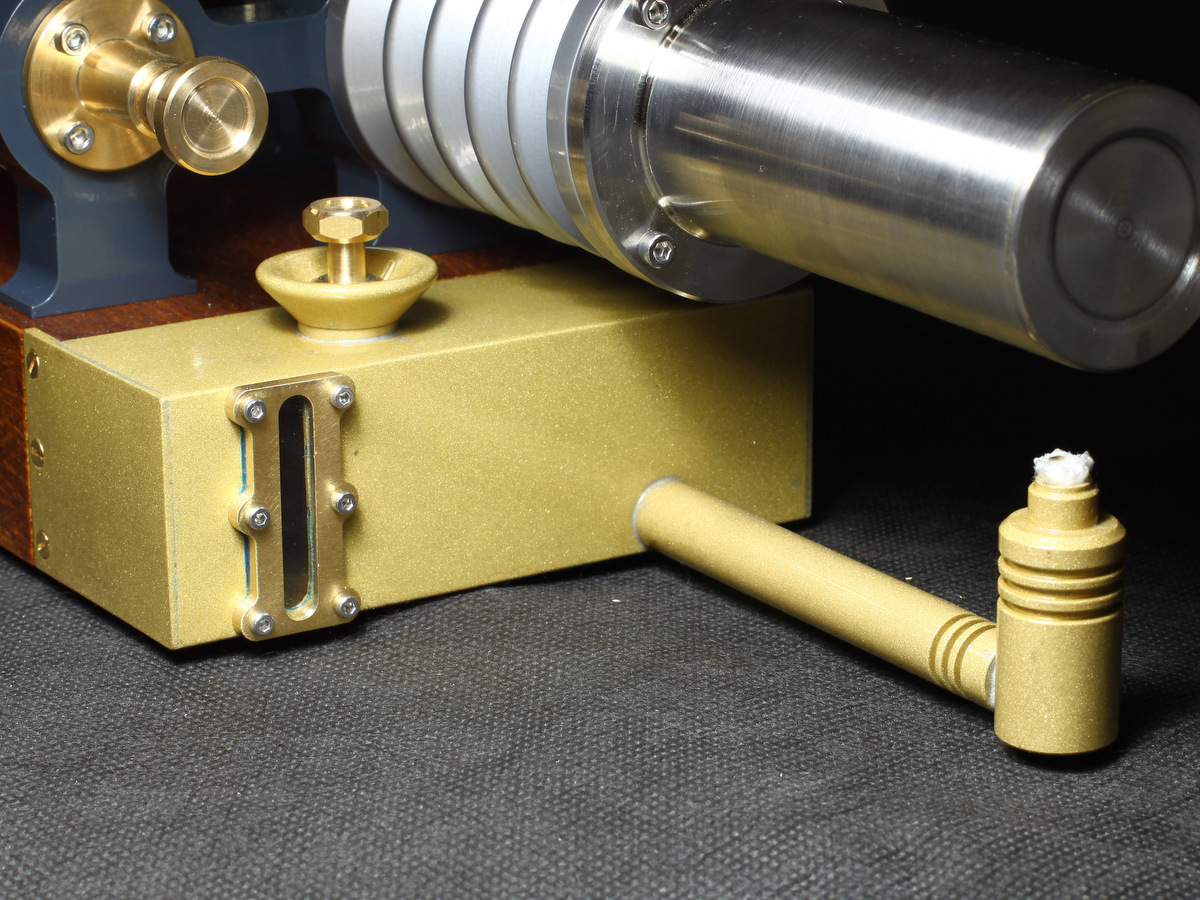

- milled milled parts Brass, steel, stainless steel and silver steel

- Raw material for the turned parts

- Cylinder sleeve made of hydraulic cylinder tube

- Flywheel and pulley made of cast steel < li>

0 of 0 reviews

Login

Cutsomers also bought

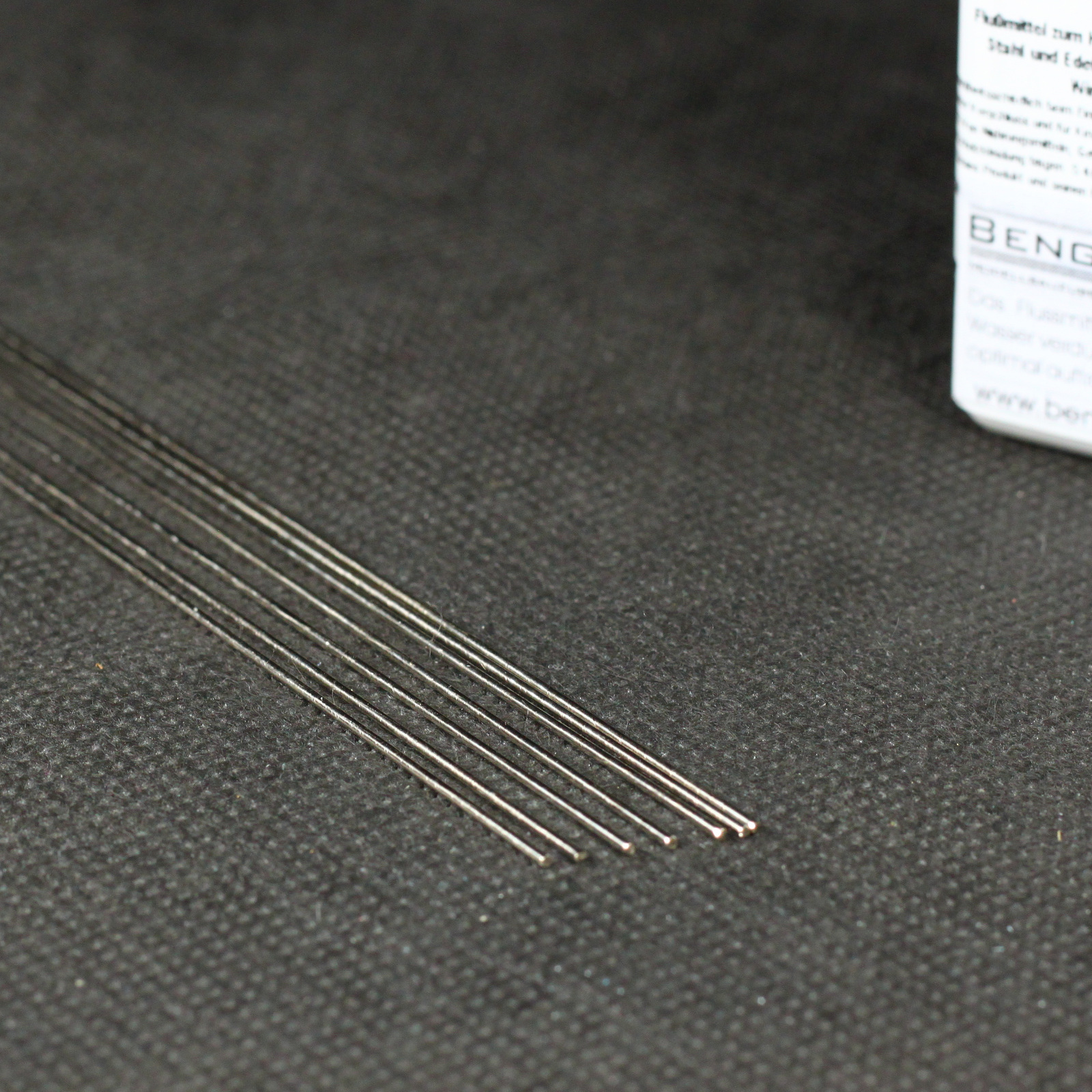

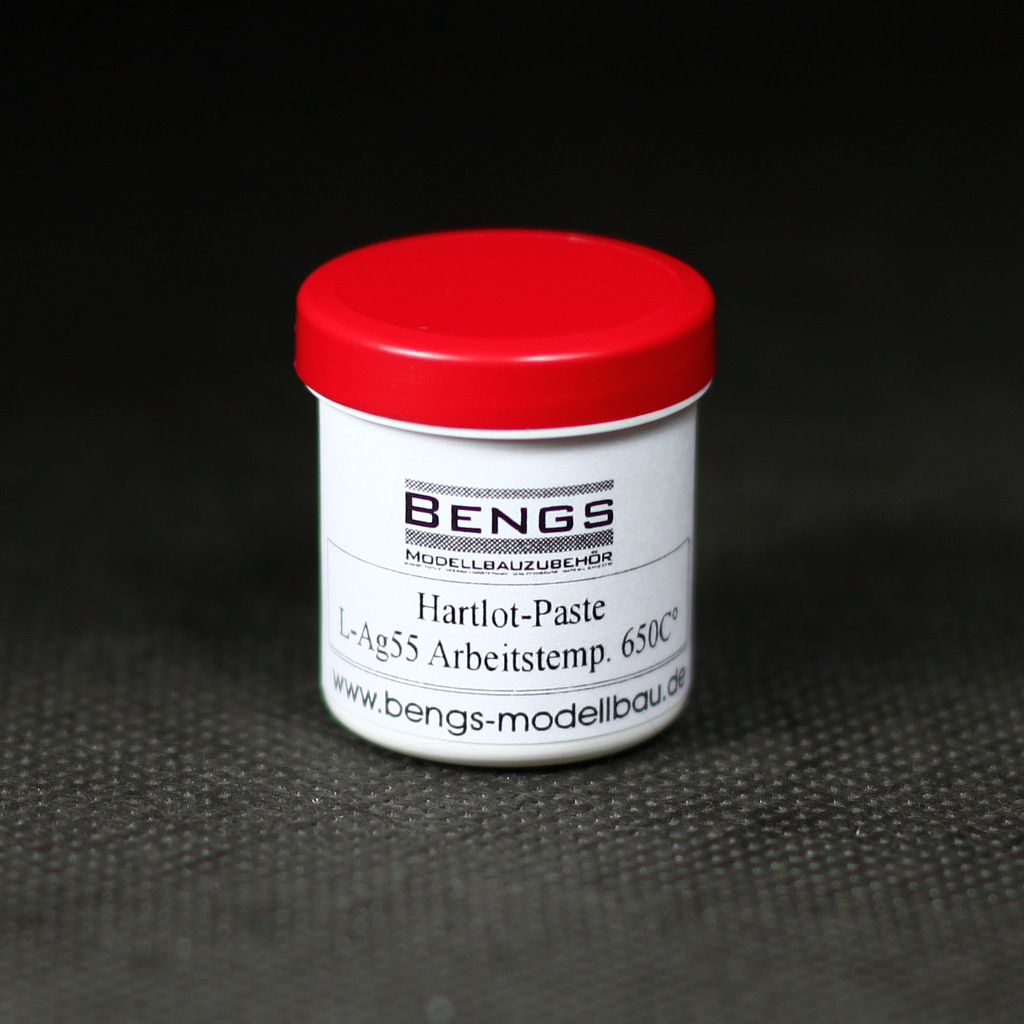

Content: 0.05 Kilogramm (€160.00* / 1 Kilogramm)

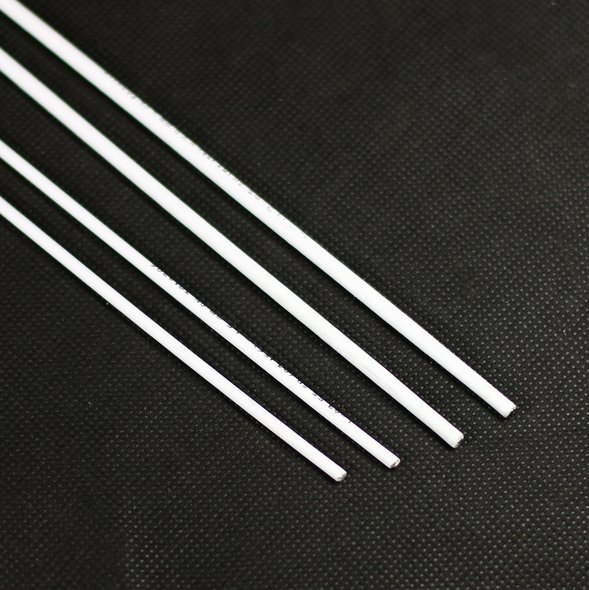

Content: 10 Gramm (€181.00* / 100 Gramm)