Vulcanized fiber sealing rings DIN 7603

Product number:

403981

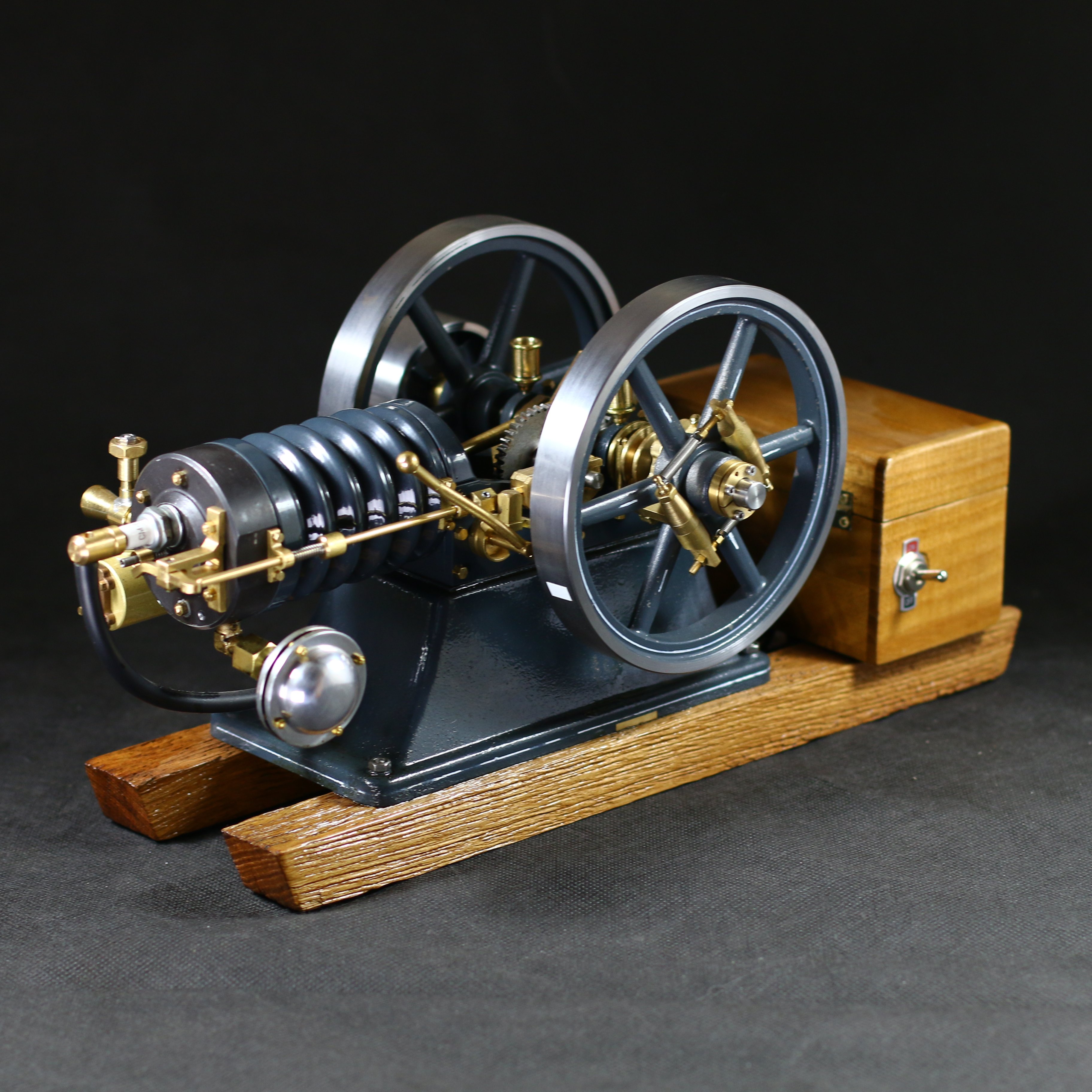

Product information "Vulcanized fiber sealing rings DIN 7603"

Suitable for sealing compressed air connections in the pneumatic sector or in model building to the tight steam lines and screw connections. Very heat resistant. And resistant to very many aggressive media. Ideal for use with steam engine models.

We also have the vulcanized fiber sealing rings in the Spar-Set in a clear folding box. Save 20% on this Stay.

All diameter 1mm height.

10 pieces per packing unit

The following vulcanic fiber sealing rings are available:

- Internal diameter 4mm External diameter 8mm Height 1mm

- Internal diameter 5mm External diameter 9mm Height 1mm

- Internal diameter 6mm External diameter 10mm Height 1mm

- Internal diameter 8mm External diameter 12mm Height 1,5mm

- Internal diameter 10mm External diameter 14mm Height 1,5mm

- Inner diameter 12mm External diameter 16mm Height 1,5mm

- Internal diameter 13mm (G 1/4) External diameter 17mm Height 1,5mm

Vulcan fiber sealing rings DIN 7603 40398 in hinged box

- 10x Internal diameter 4mm External diameter 8mm Height 1mm

- 10x Internal diameter 5mm External diameter 9mm Height 1mm

- 10x Internal diameter 6mm External diameter 10mm Height 1mm

- 10x Internal diameter 7mm External diameter 11mm Height 1mm

- 10x Internal diameter 8mm External diameter 12mm Height 1,5mm

- 10x Internal diameter 10mm External diameter 14mm Height 1,5mm

- 10x Internal diameter 12mm External diameter 16mm Height 1,5mm

- 10x Internal diameter 14mm External diameter 18mm Height 1,5mm

- 10x Internal diameter 16mm External diameter 20mm Height 1,5mm

- 10x Internal diameter 18mm External diameter 22mm Height 1,5mm

Login