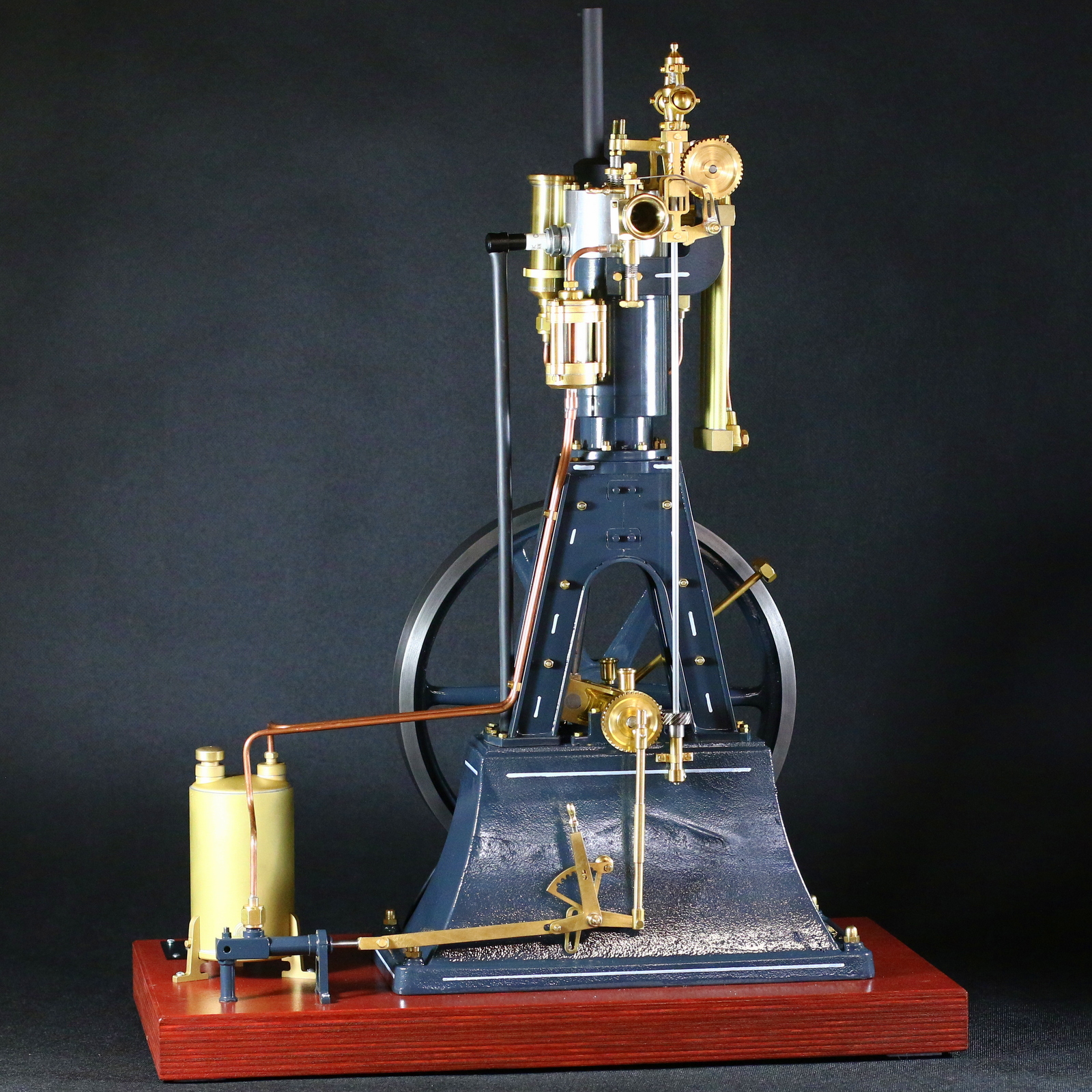

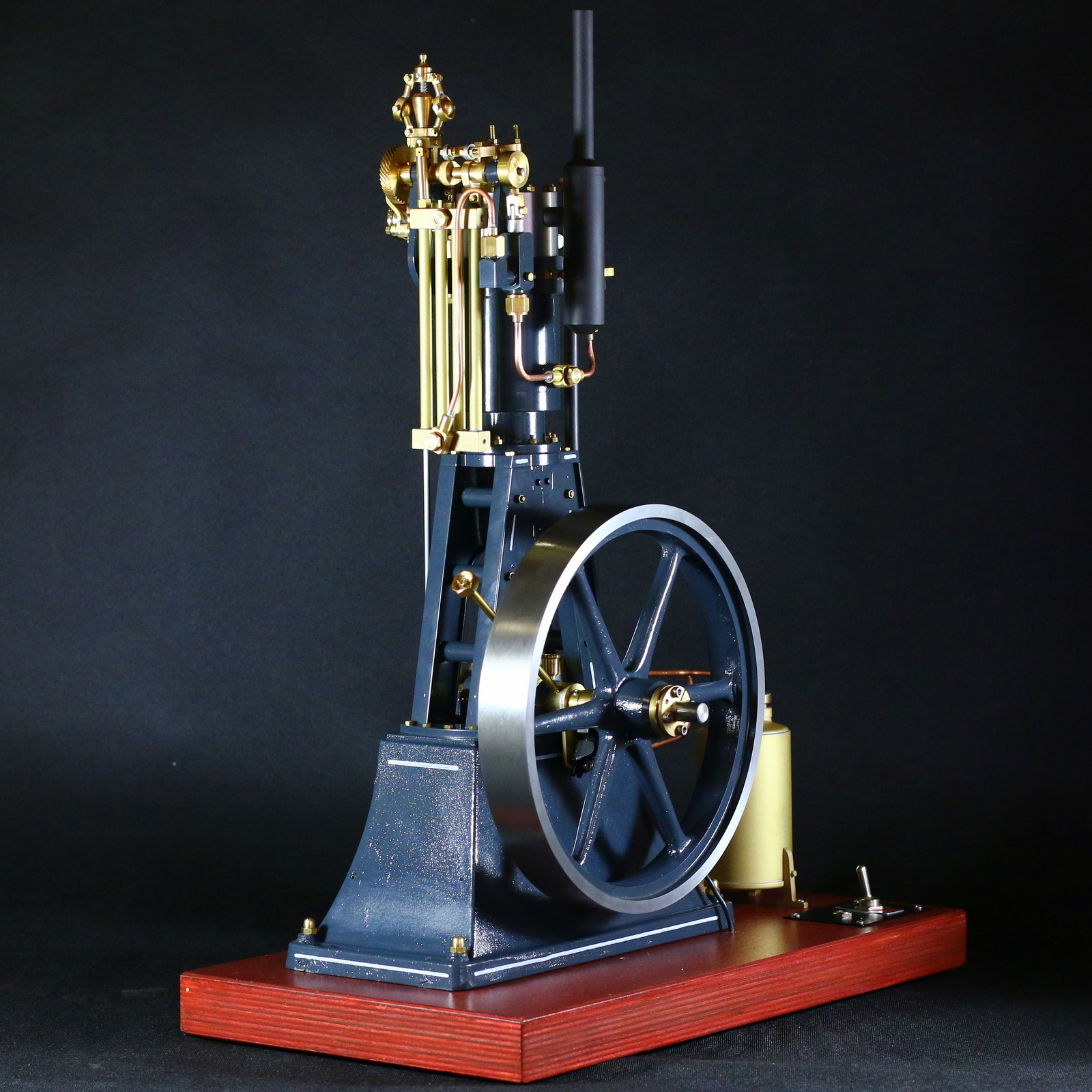

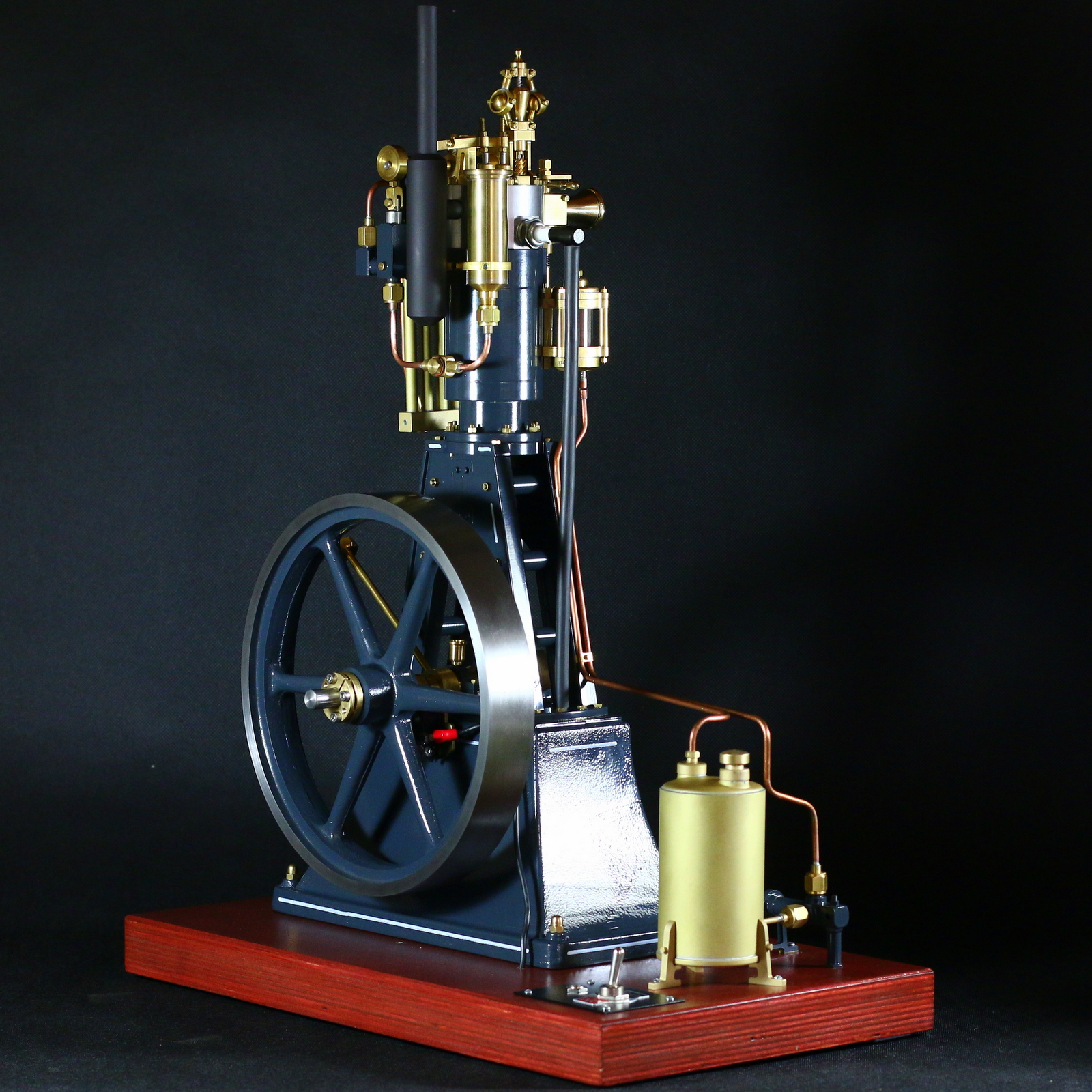

vertical combustion engine Jonas

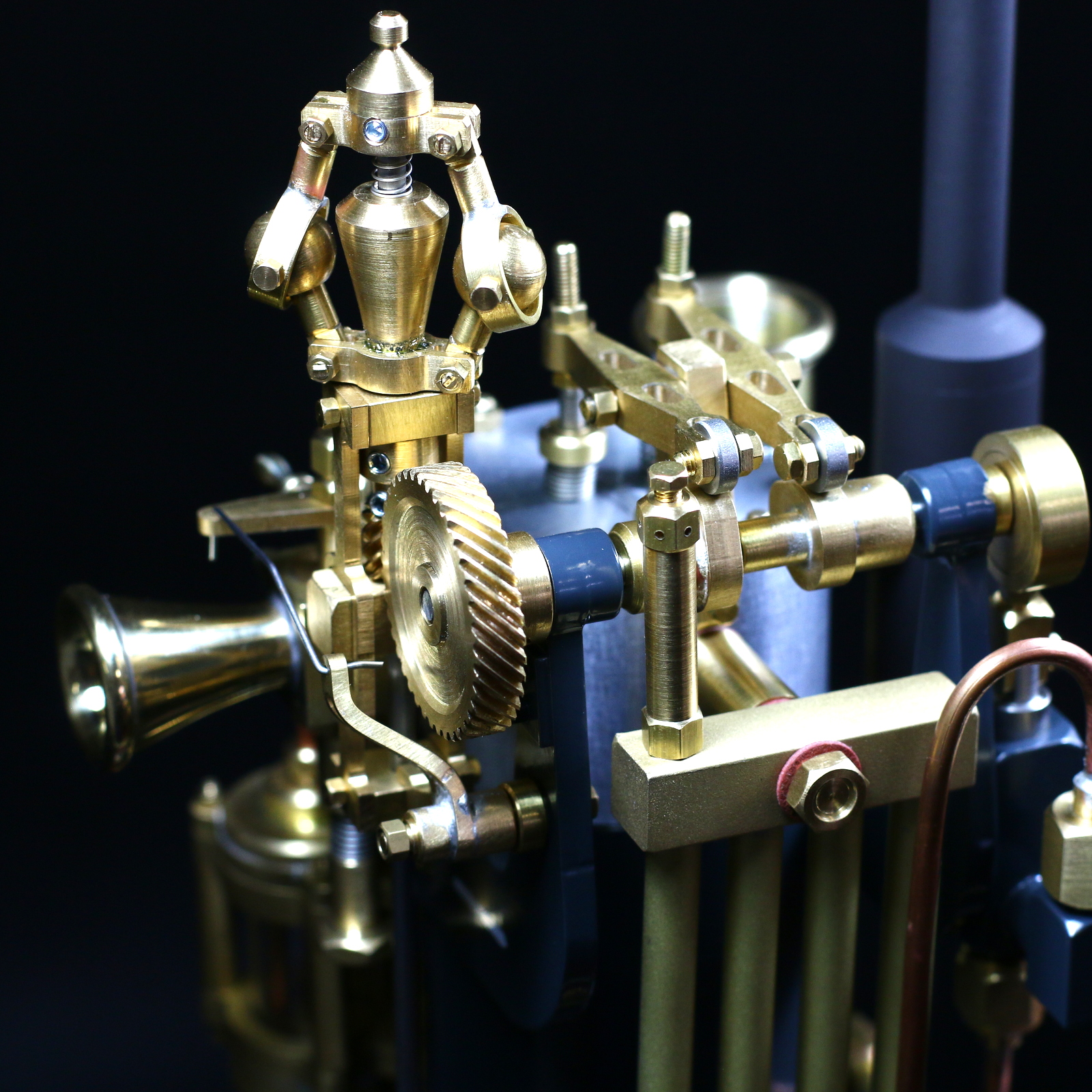

The Jonas vertical combustion engine was based on the appearance of the early diesel engines that were created at the beginning of the 20th century. A frame that has the shape of an A was typical. In addition, the early diesel engines were mostly long-stroke engines, which resulted in a slim and tall design. The overhead camshaft, which was driven by a long vertical shaft, was also typical. Back then, as now in our model, the speed was controlled via a centrifugal governor mounted on top of the vertical shaft. Our combustion engine runs on gasoline, but operation on diesel is not possible.

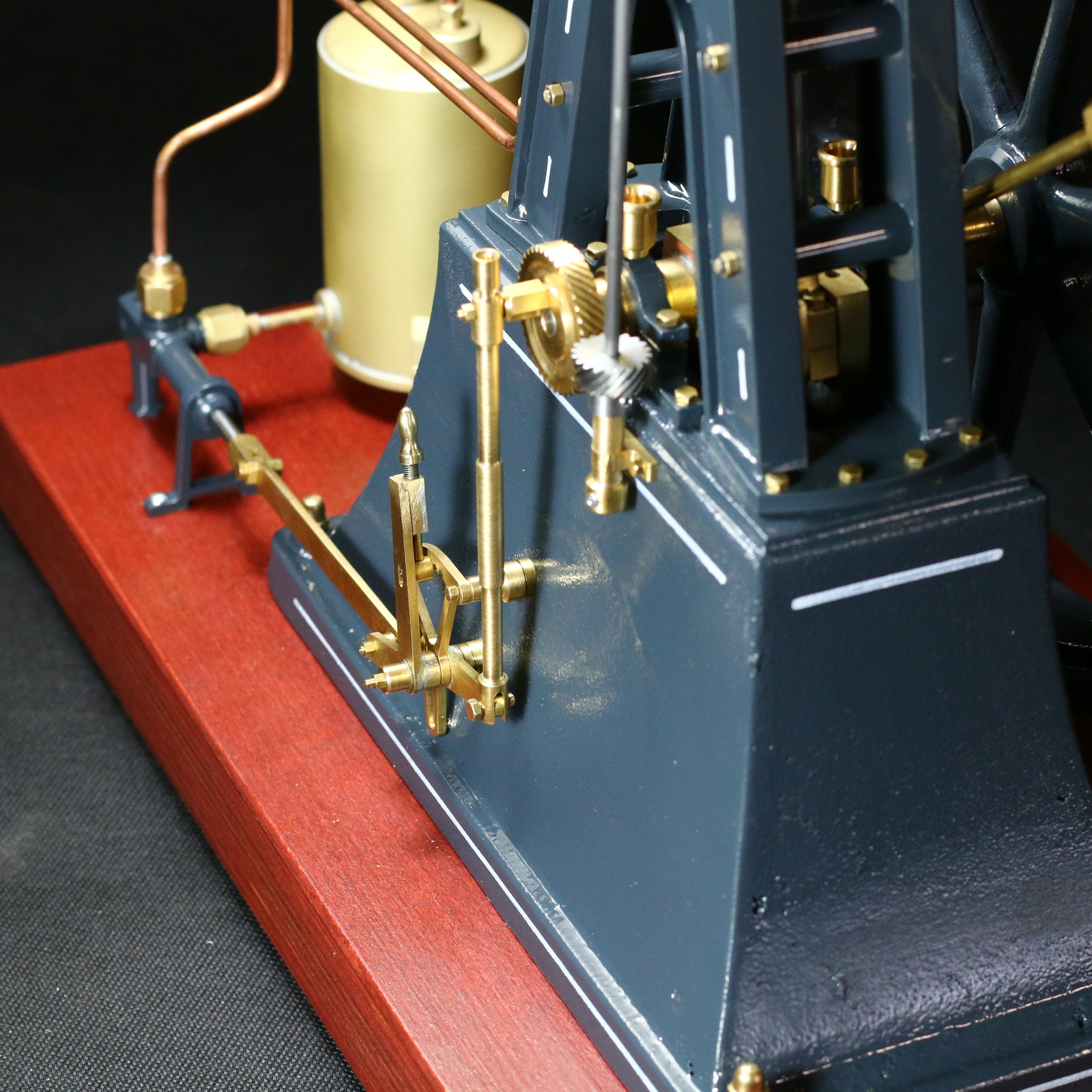

- Speed control via centrifugal governor

- Carburetor with adjustable throttle valve

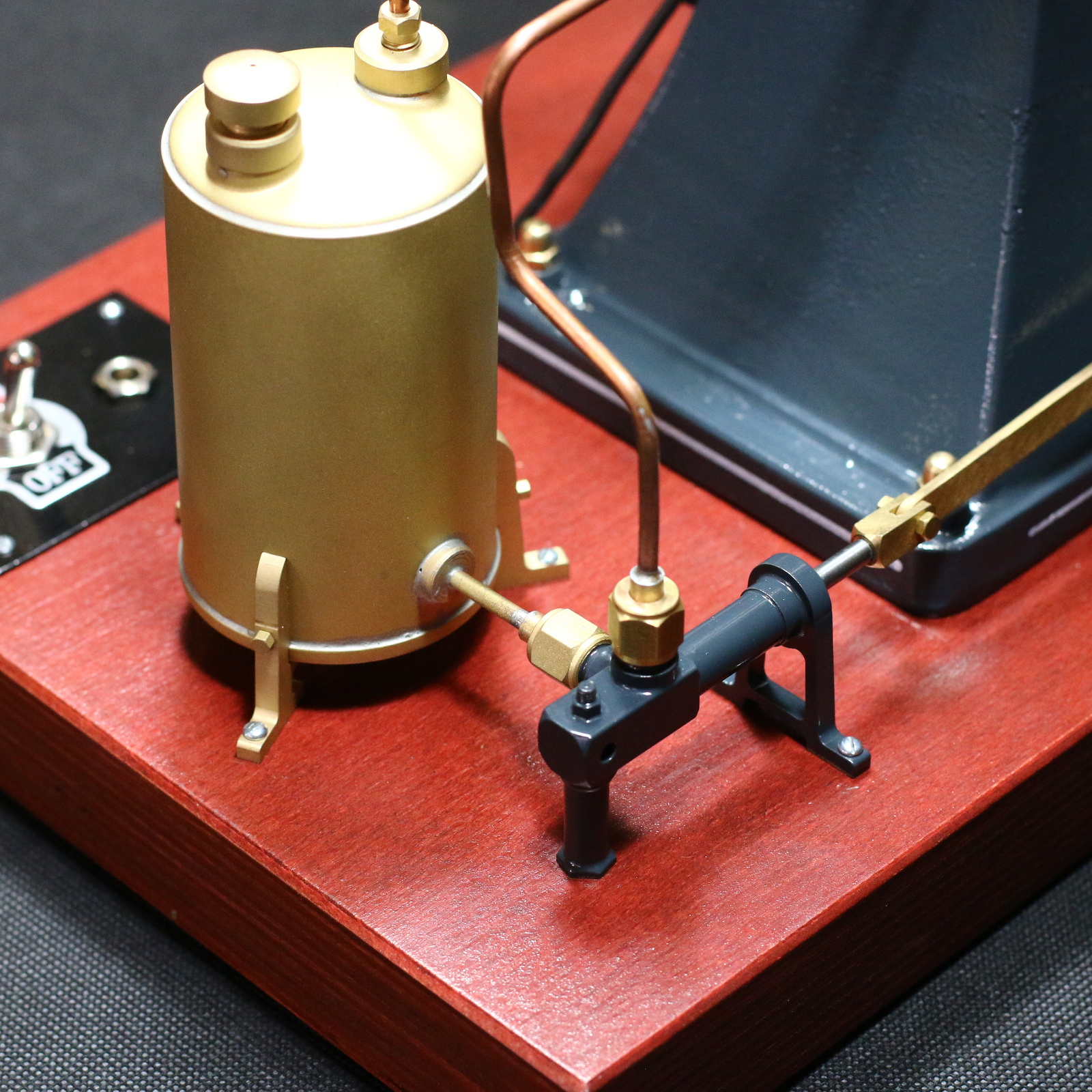

- Cooling circuit with cooling water pump

- Fuel pump delivery rate adjustable

- Ignition timing adjustment

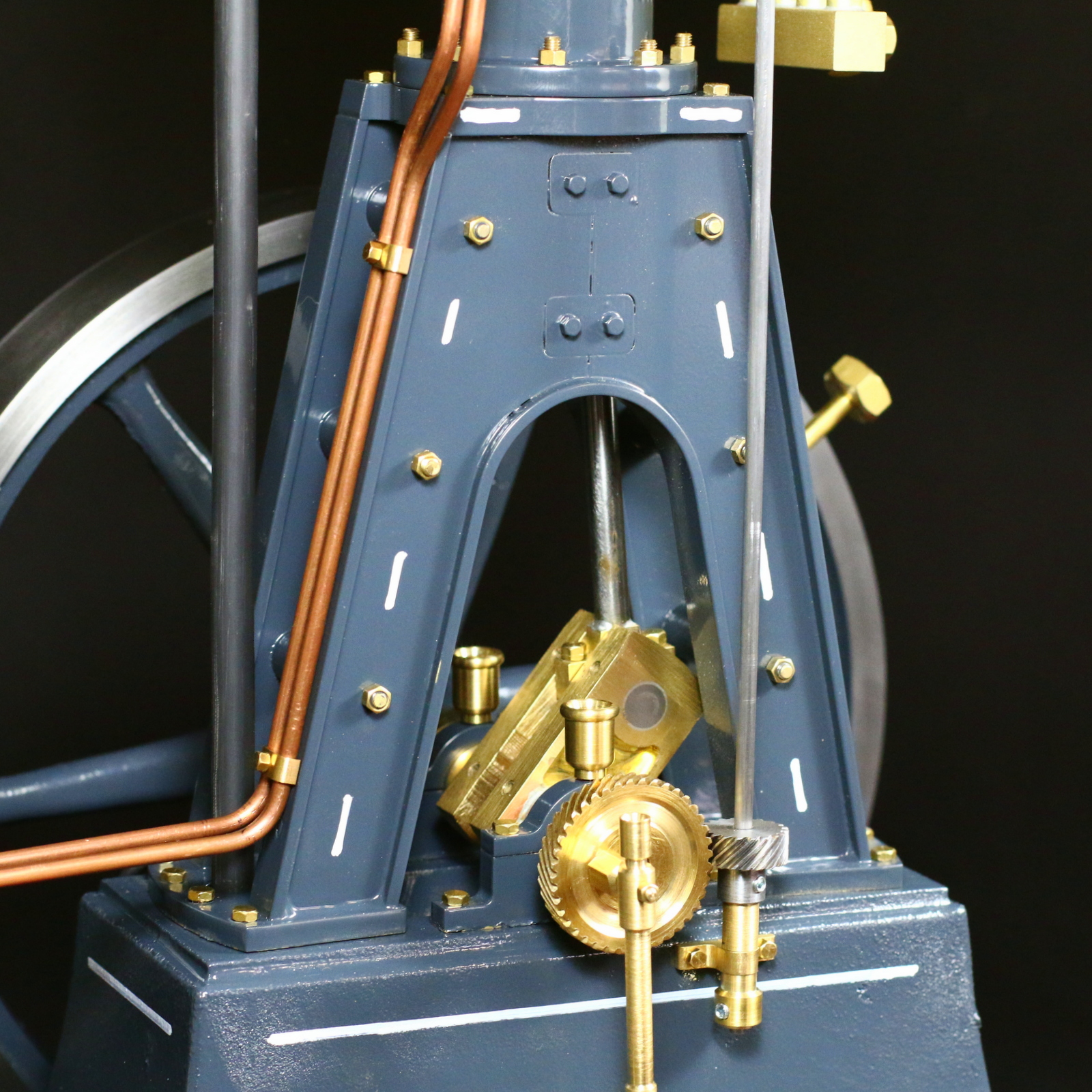

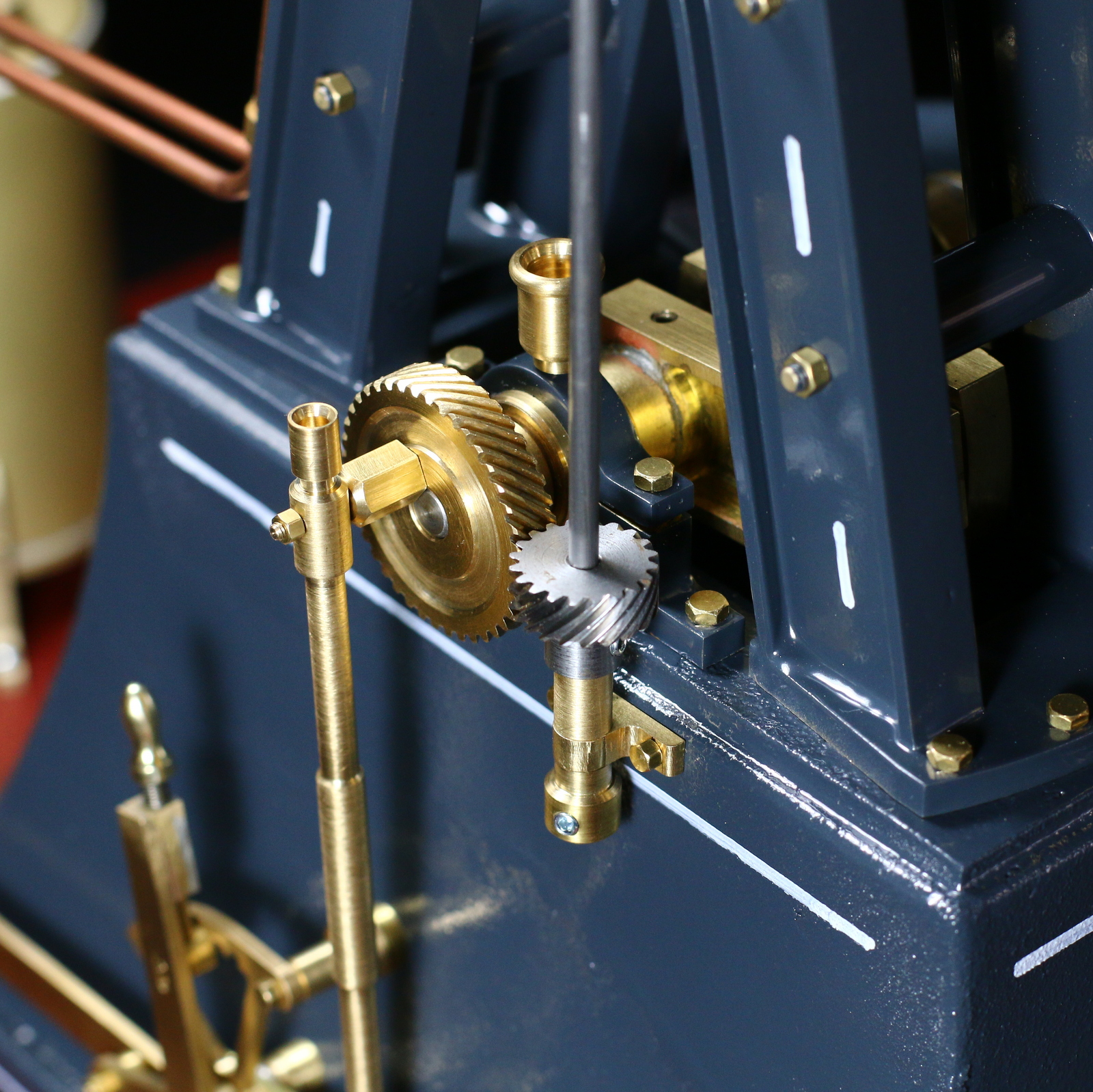

- Camshaft drive via screw wheel 45°

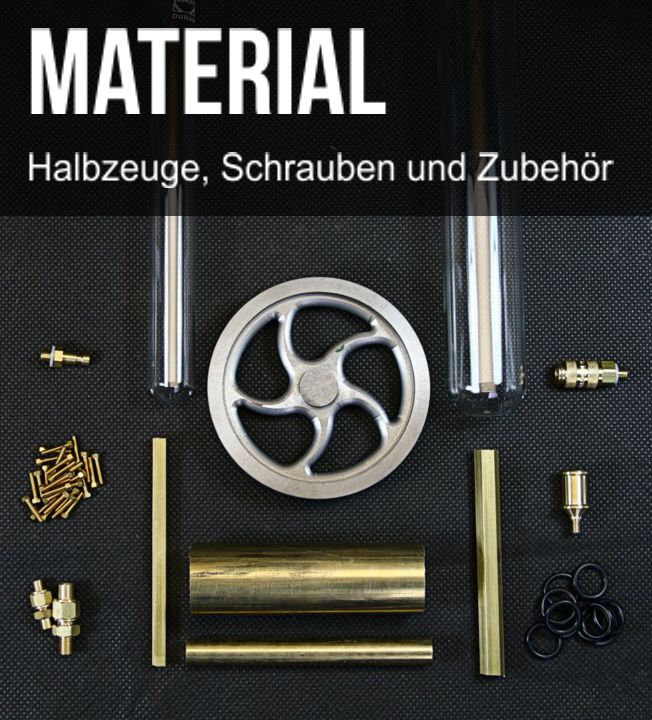

With the material kit for the water-cooled 4-stroke engine "Jonas" you can build a fully functional internal combustion engine yourself. The material kit contains all the necessary parts including the ignition. The engine has functioning speed control using a centrifugal governor. A cooling water pump pumps water through a radiator into the cylinder jacket and back again. The engine also has a fuel pump that pumps the fuel towards the carburettor into an intermediate tank. The pumping volume of the fuel pump can be adjusted as required. The breaker ignition is located in the cast base. The ignition is supplied with voltage via a 12 V 2 A power supply. The power supply is also included.

Dimensions of the model combustion engine 'Jonas':

- Height with wooden base: 500mm

- Dimensions of the base plate: 350mm x 210mm

- Piston diameter: 25mm

- Flywheel D.: 200mm

- Speed speed: 200-600 rpm

- Weight: 11.8kg

The machine base of the vertical stationary motor is a heavy gray cast iron base. This heavy base gives the model sufficient stability. The piston of the combustion engine is also made from gray cast iron round material. In this engine the piston also has a piston ring. The piston ring is already included in the kit. A hydraulic cylinder tube is used as a cylinder, which is already finished on the inside and has an excellent surface. The cylinder head is made of aluminum, the cooling jacket is hollow and is flushed with cooling water via a cooling water pump. The 200mm flywheel is made of gray cast iron and can be ordered pre-machined upon request. Most of the attachments and the machine frame are made of brass.

Speed control

The speed of this model is controlled via the carburettor. By being able to regulate the amount of air supplied. The carburettor is connected to a centrifugal governor via a linkage. This means you can set the engine to a desired speed and this is maintained even under load using the centrifugal governor.

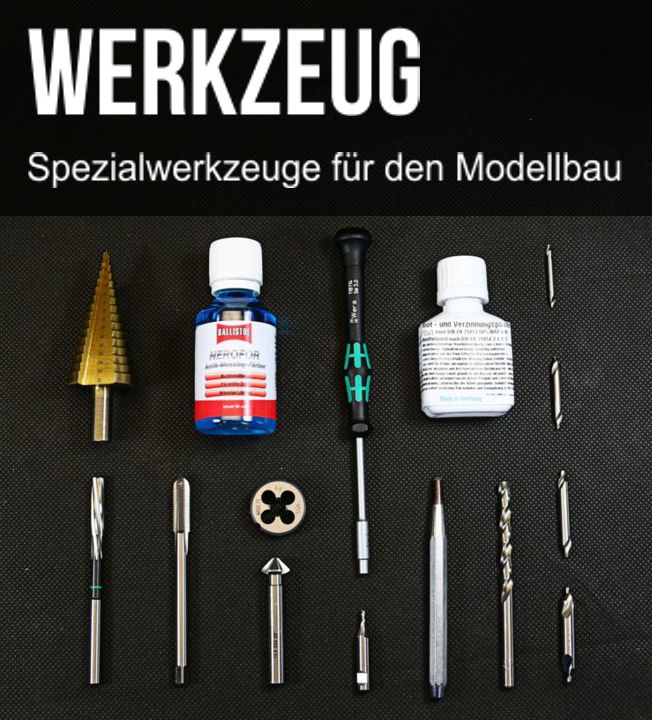

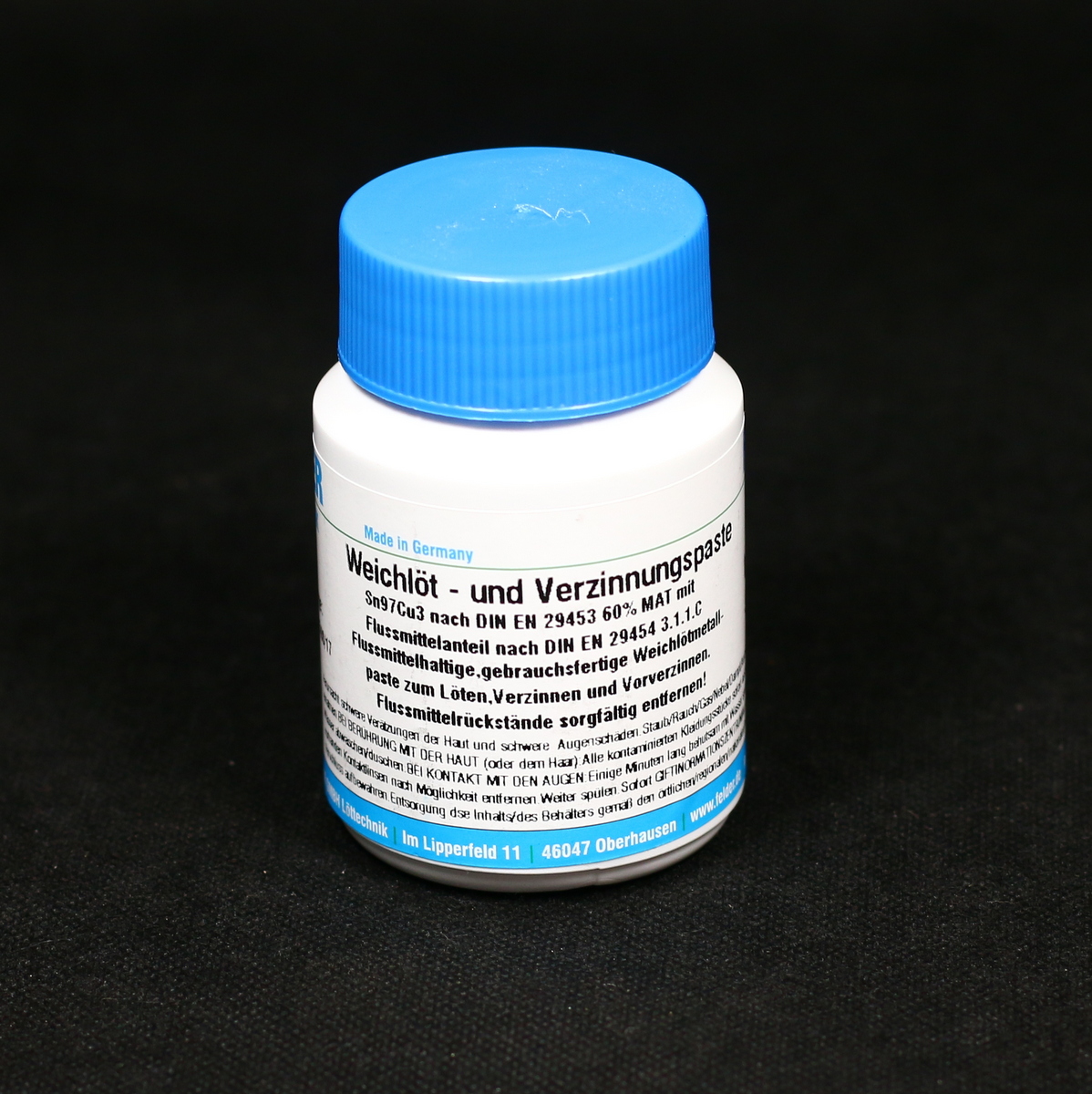

All materials required to build the internal combustion engine "Jonas" screws, nuts, springs and ignition parts are included in the kit. All milled parts are prepared so that they only need to be deburred and possibly drilled. To build the vertical stationary motor, you need a lathe, a drill and a gas burner for soft soldering. The following hand tools are also required (tap M2, M3, M4, M6x0.75, M8x0.75, M10x1 die M2, M3, M4, M6x0.75, M8x0.75, M10x1 Reamer 3H7, 4H7 6H7, 8H7, 10H7) Files and a drill set are necessary. All you need to wire the ignition is a pair of side cutters, wire strippers and a soldering iron.

If you would like to find out in advance which work steps you have to carry out when manufacturing this combustion engine, take a look at our Bengs model building magazine Construction report of the vertical stationary engine “Jonas” at. On this page you can see the illustrated report on how the stationary motor material set is processed.

The scope of delivery includes:

Login