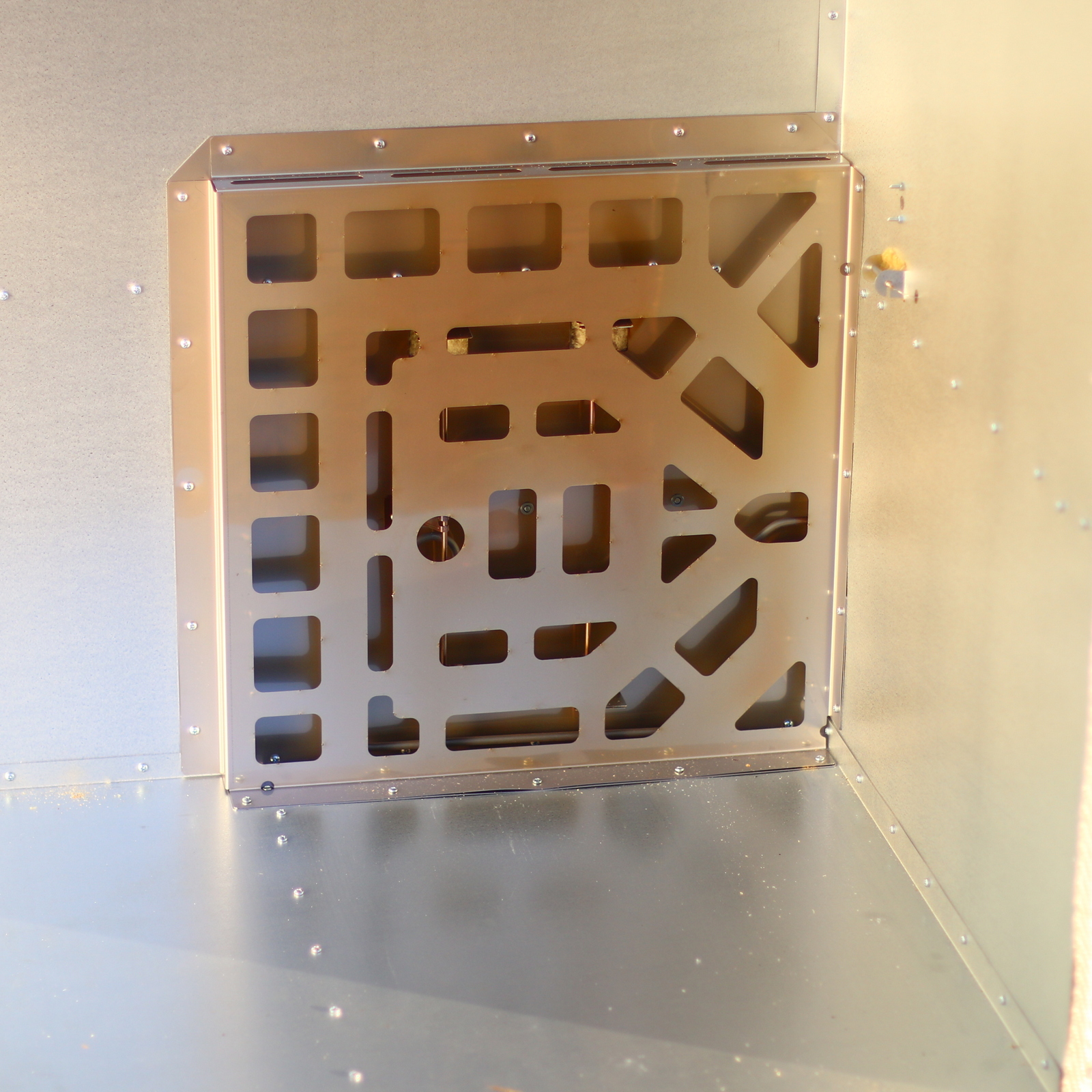

Powderoven XL160x85x60cm

The baking chamber has dimensions of 160 x 85 x 60 cm (57 cm, in the area of the heating element). The external dimensions of the powder oven are 177 cm high, 101 cm wide and 71 cm deep. the oven reaches 180°C in about 25 minutes and the maximum temperature (220°C) in about 35 minutes. It requires 230 V, single phase, 50 Hz, so can be used in any work area. The powder oven only consumes 2800W, so a standard 16 amp fuse is sufficient for operation. The oven is CE marked and comes with a 24 month warranty. The temperature can be controlled with an analogue thermostat controller and set to 0°C and 220°C. It has indicator lights, an indicator when the oven has reached a set temperature.

Technical data powder oven XL160x85x60cm

- External dimensions 177x101x71 cm (H x W x D)

- Internal dimensions 160x85x60 cm (H x W x D)

- Temperature range 0-220°C / 20°C to 180°C in 25min. (220°C in 35min.)

- Temperature control

- Analog thermostat controller

- Voltage 230 V single phase (50 Hz)

- Power 2.8kW

- Materials Laser cut galvanized steel; 50mm insulation

- Weight 120kg

- Made in Lithuania (CE marked)

- Guarantee 24 months

With us you will of course receive complete customer support, after purchase, all spare parts if you need them. The oven is CE marked and comes with a 24 month warranty.

The oven is manufactured in Lithuania and delivered directly from there by courier. The oven stands directly on a pallet and is additionally secured with a frame. The oven can be easily lowered from the pallet with 2 people and then stands on wheels and is mobile. Please note the delivery time is approx. 10 working days.

Login