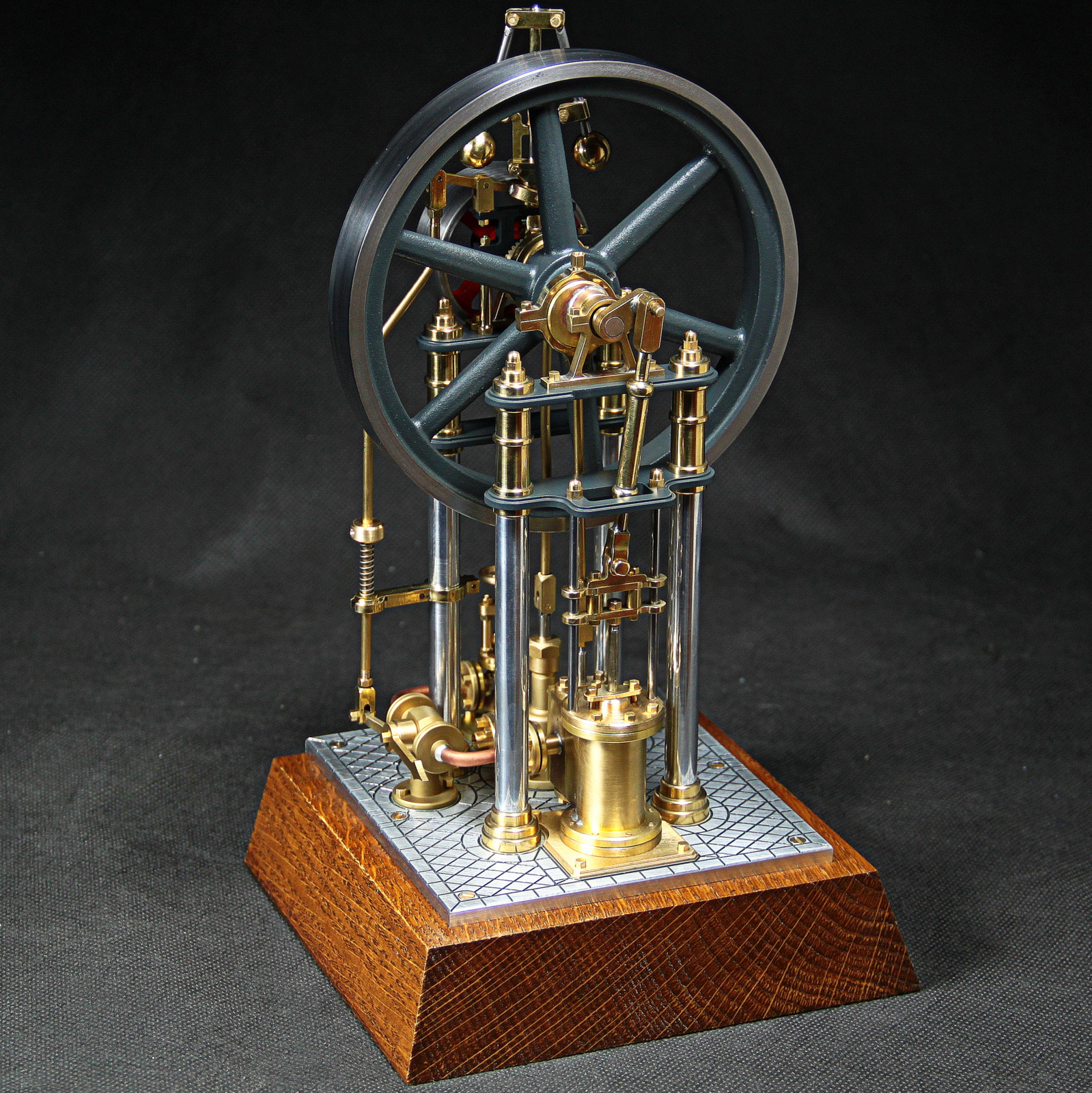

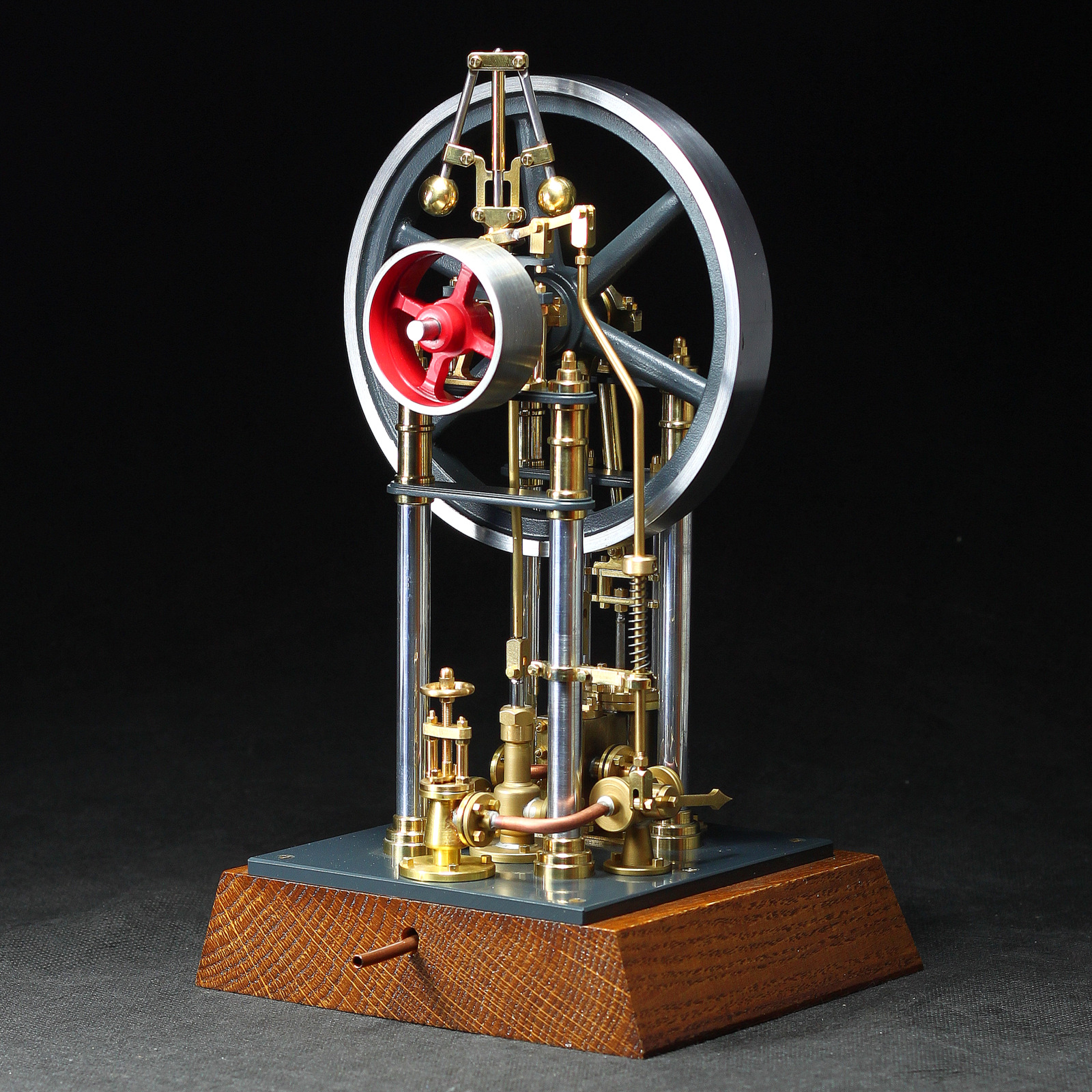

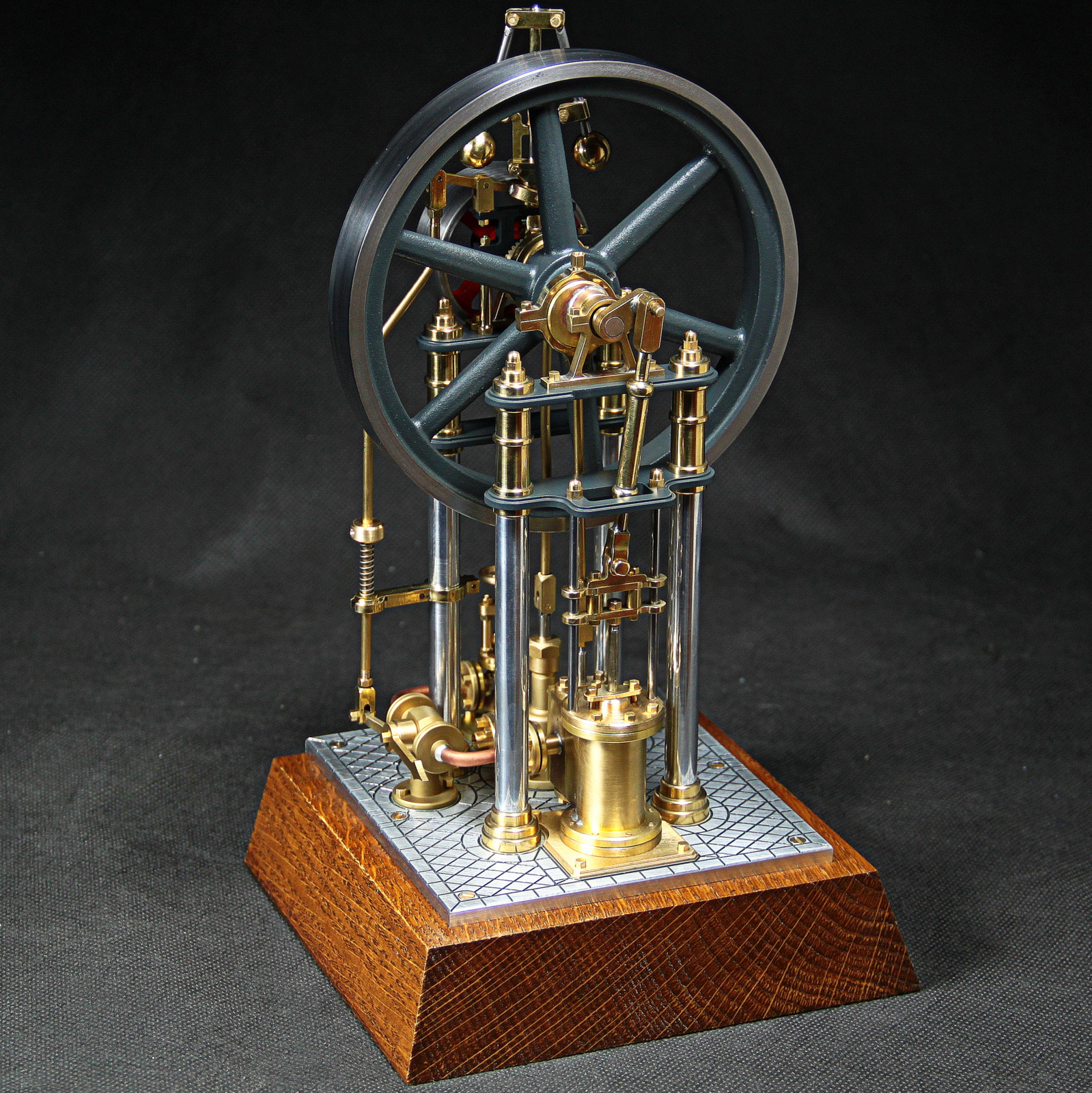

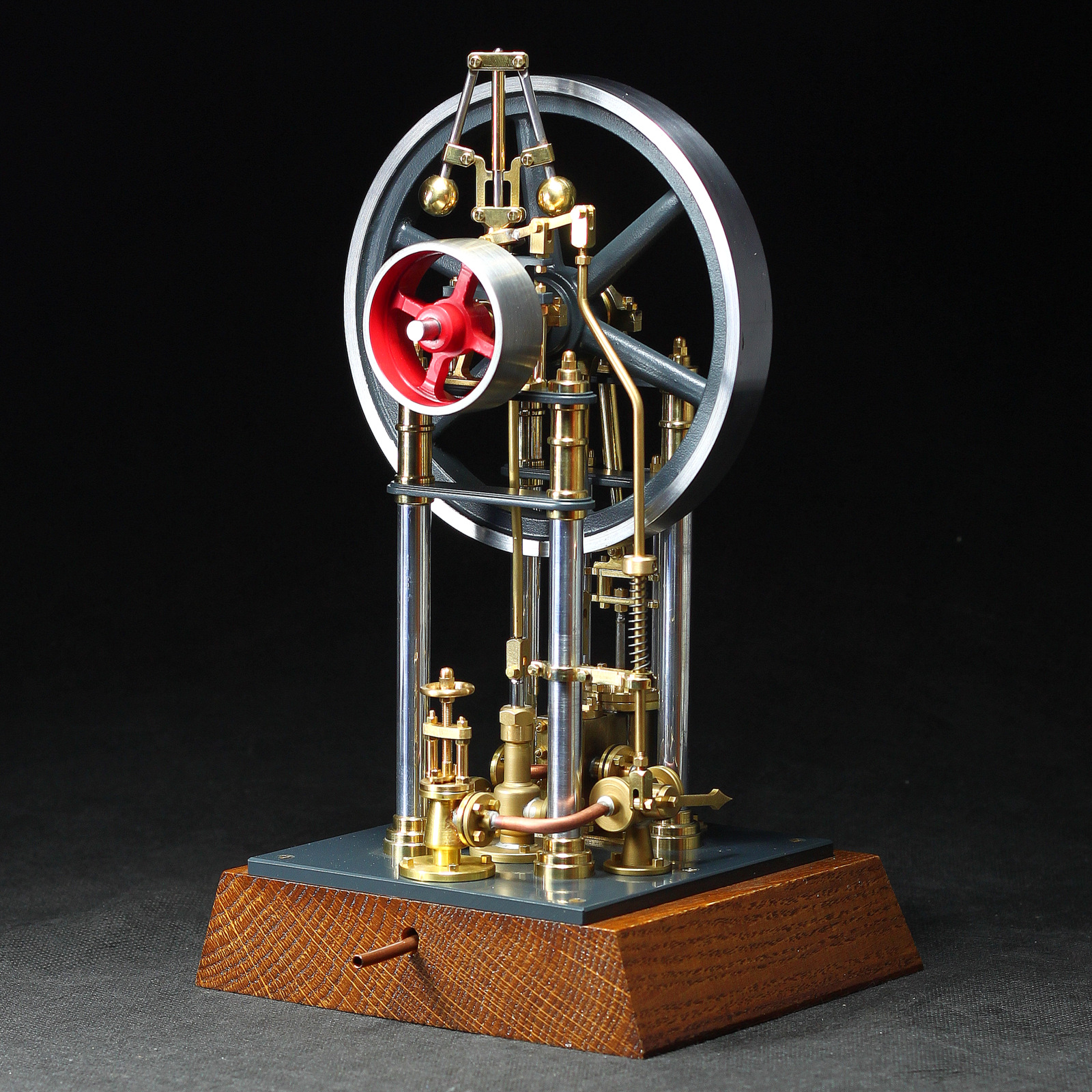

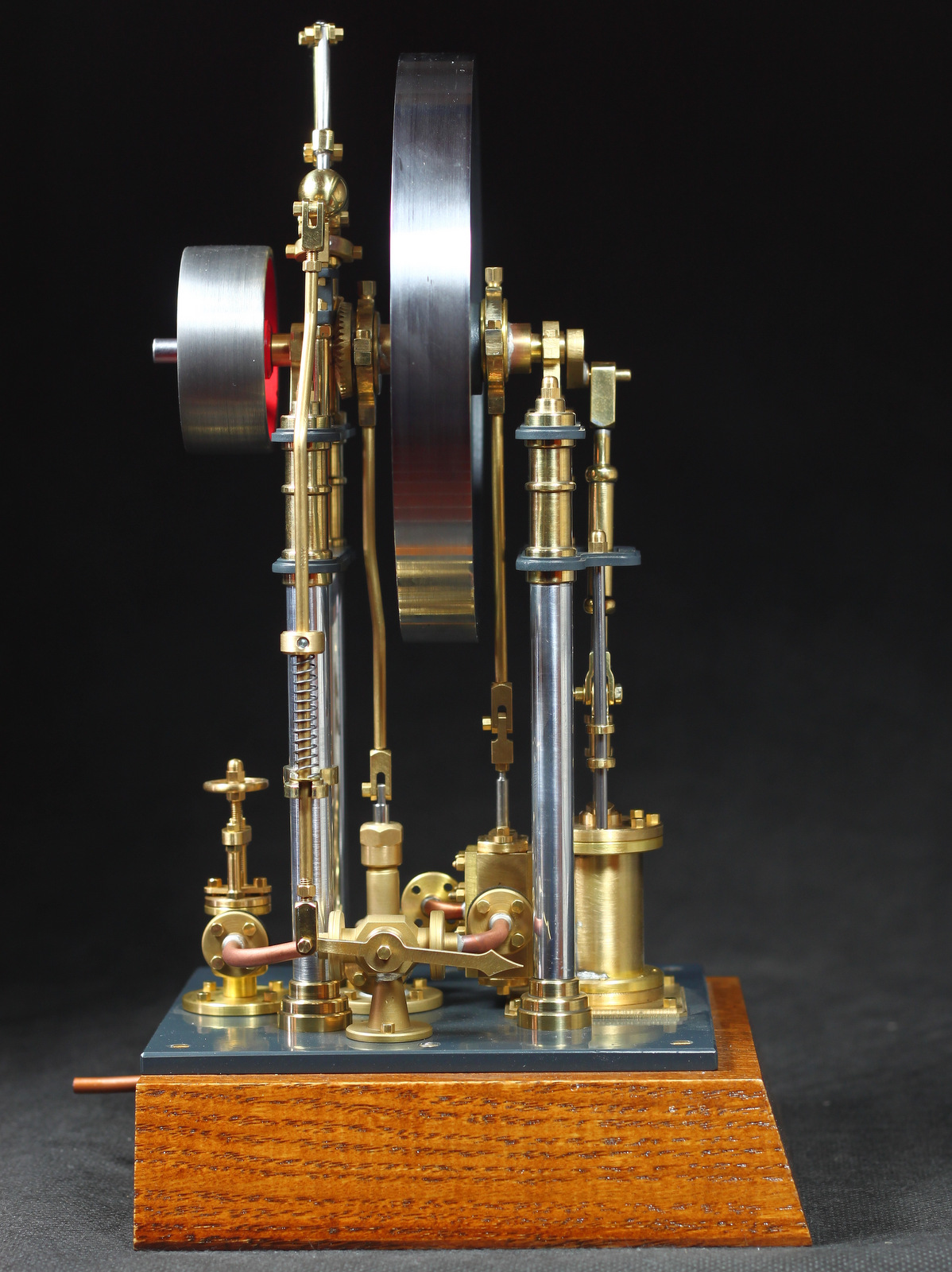

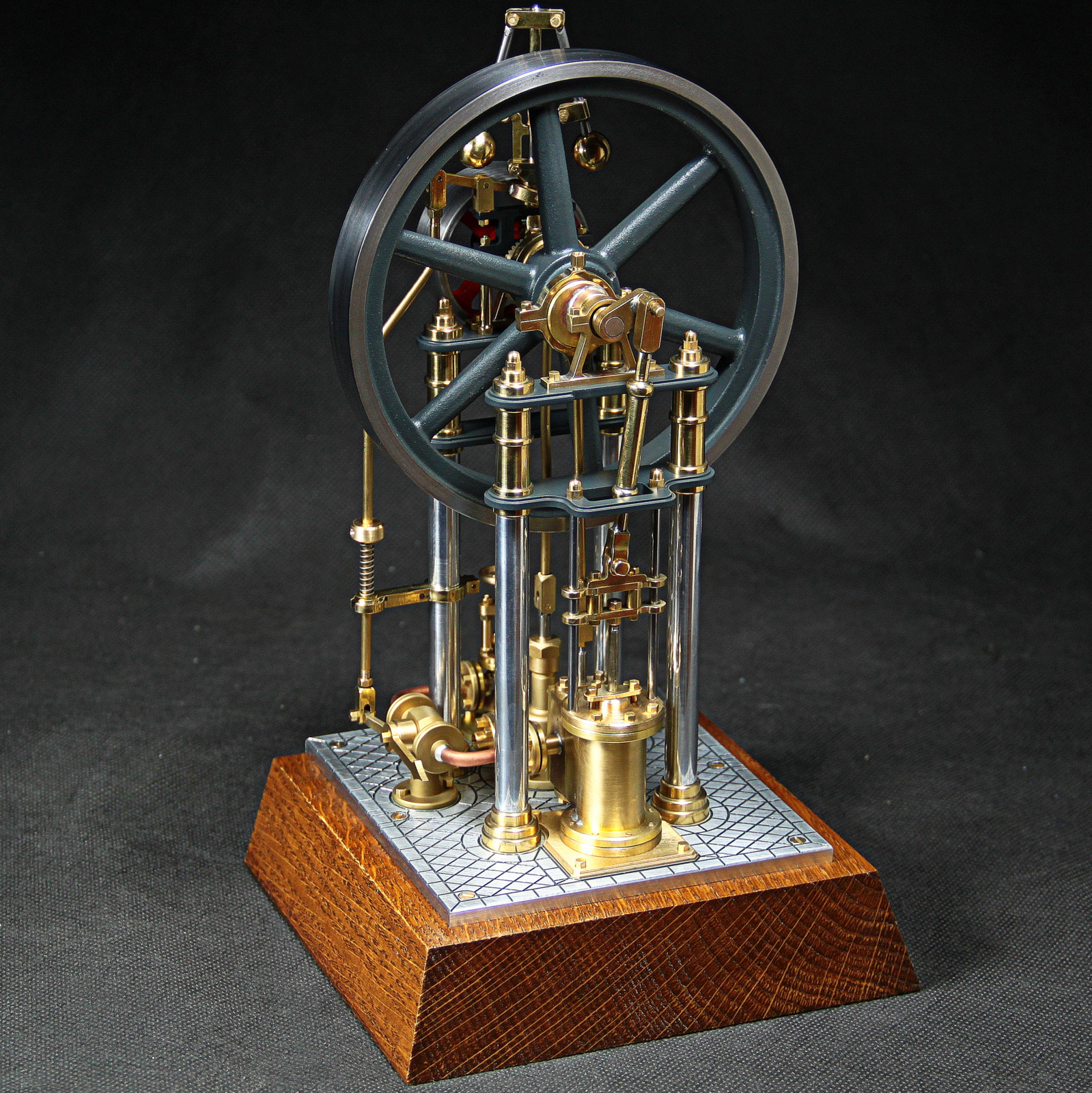

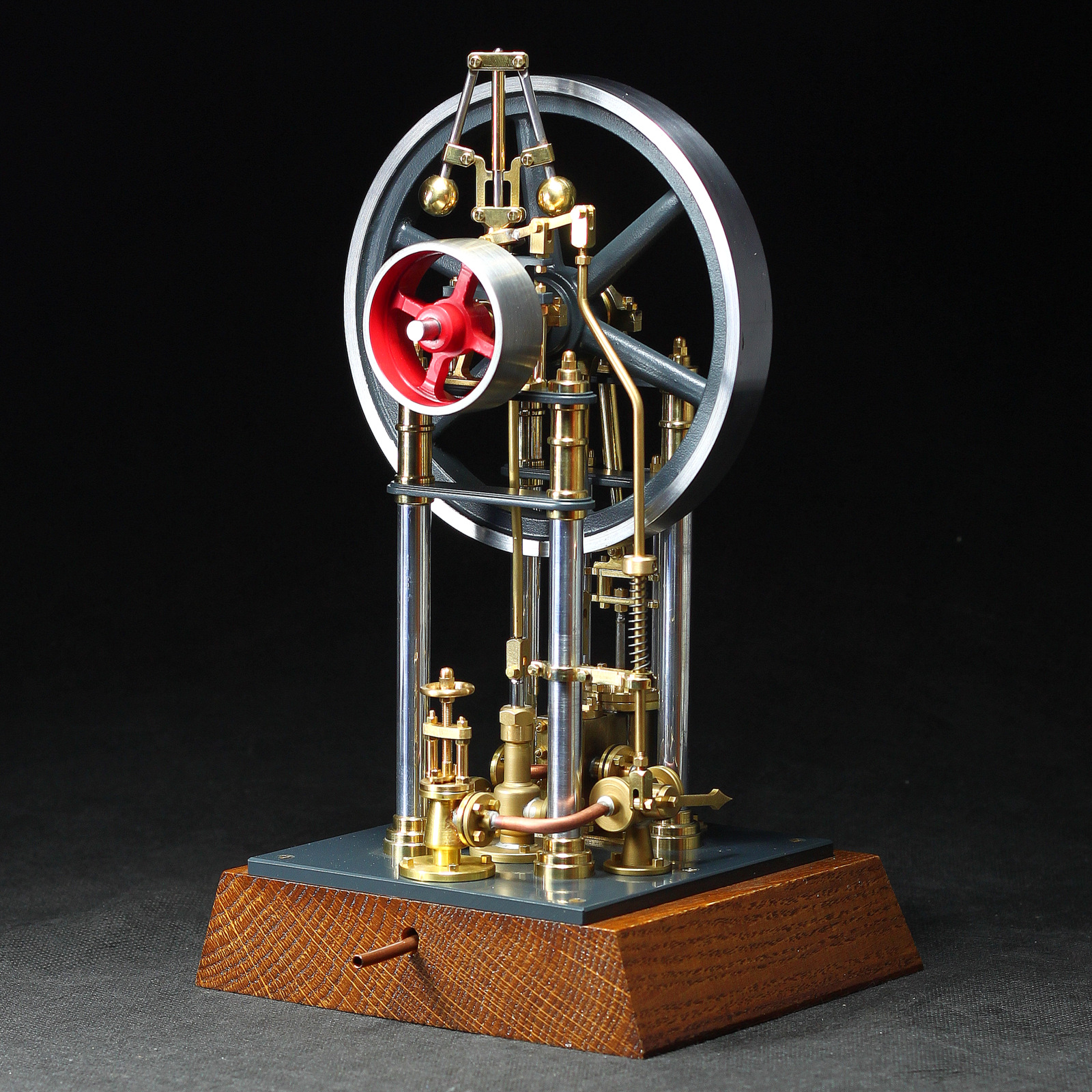

Vertical Column steam engine Donatus

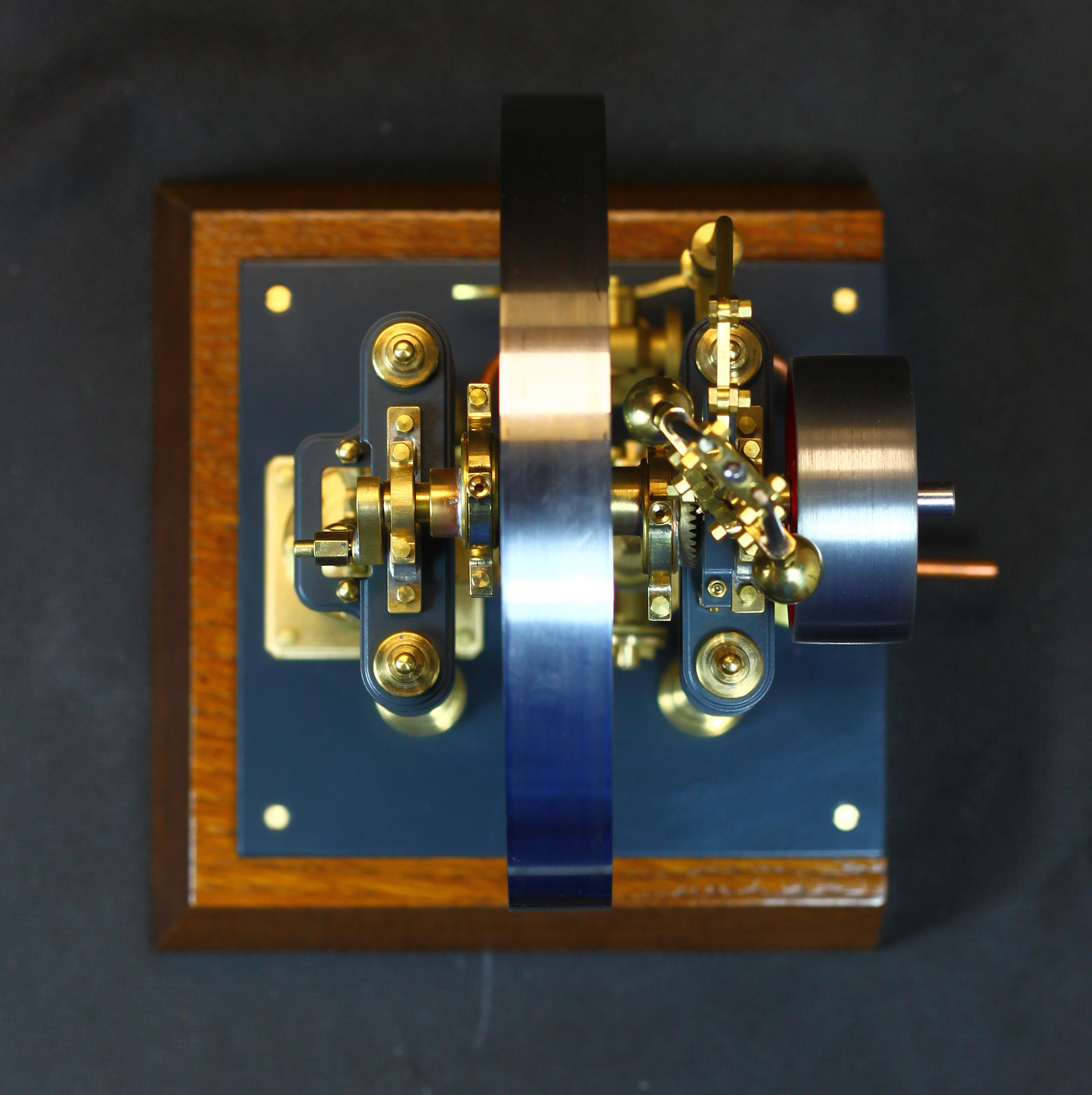

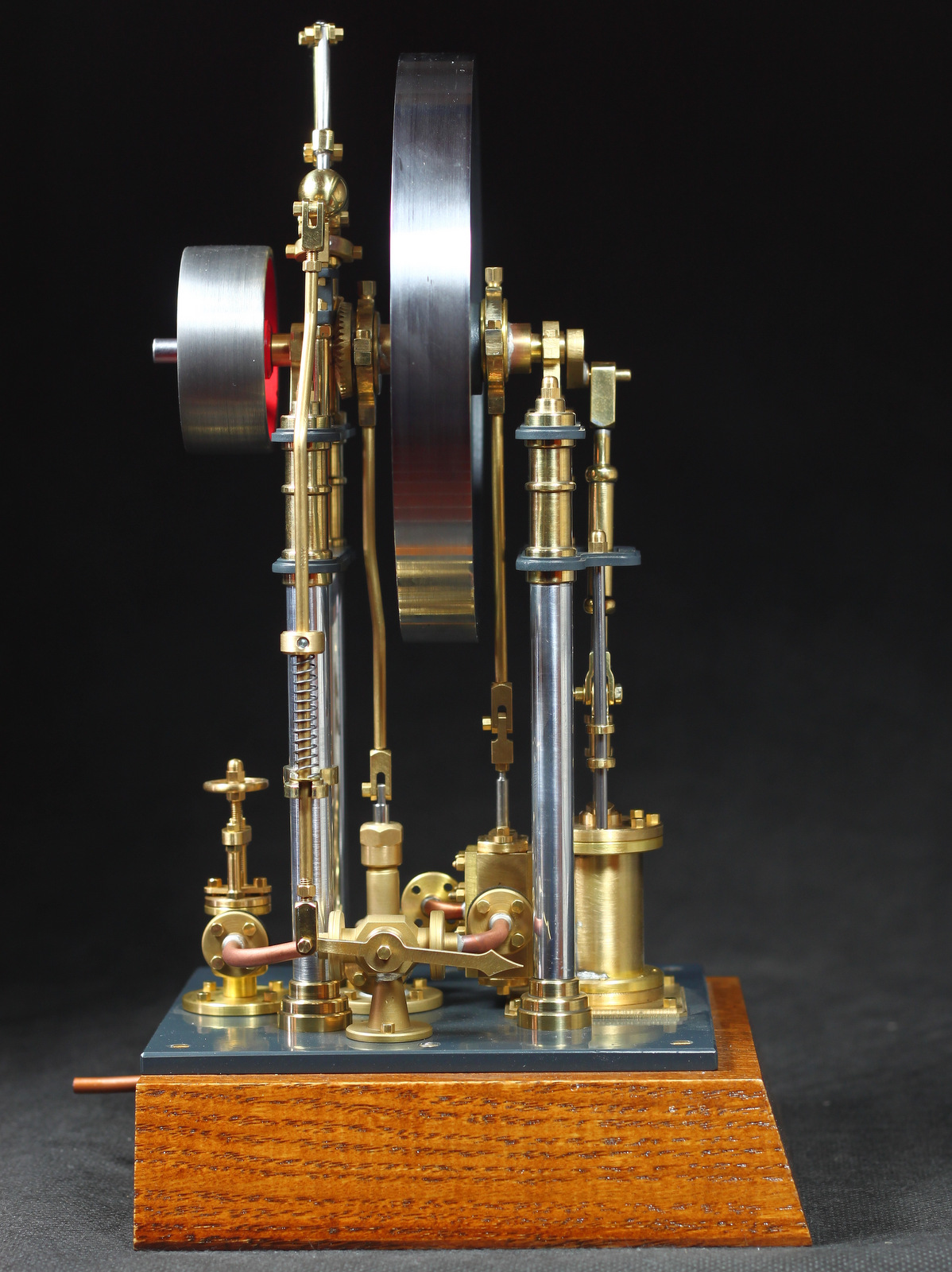

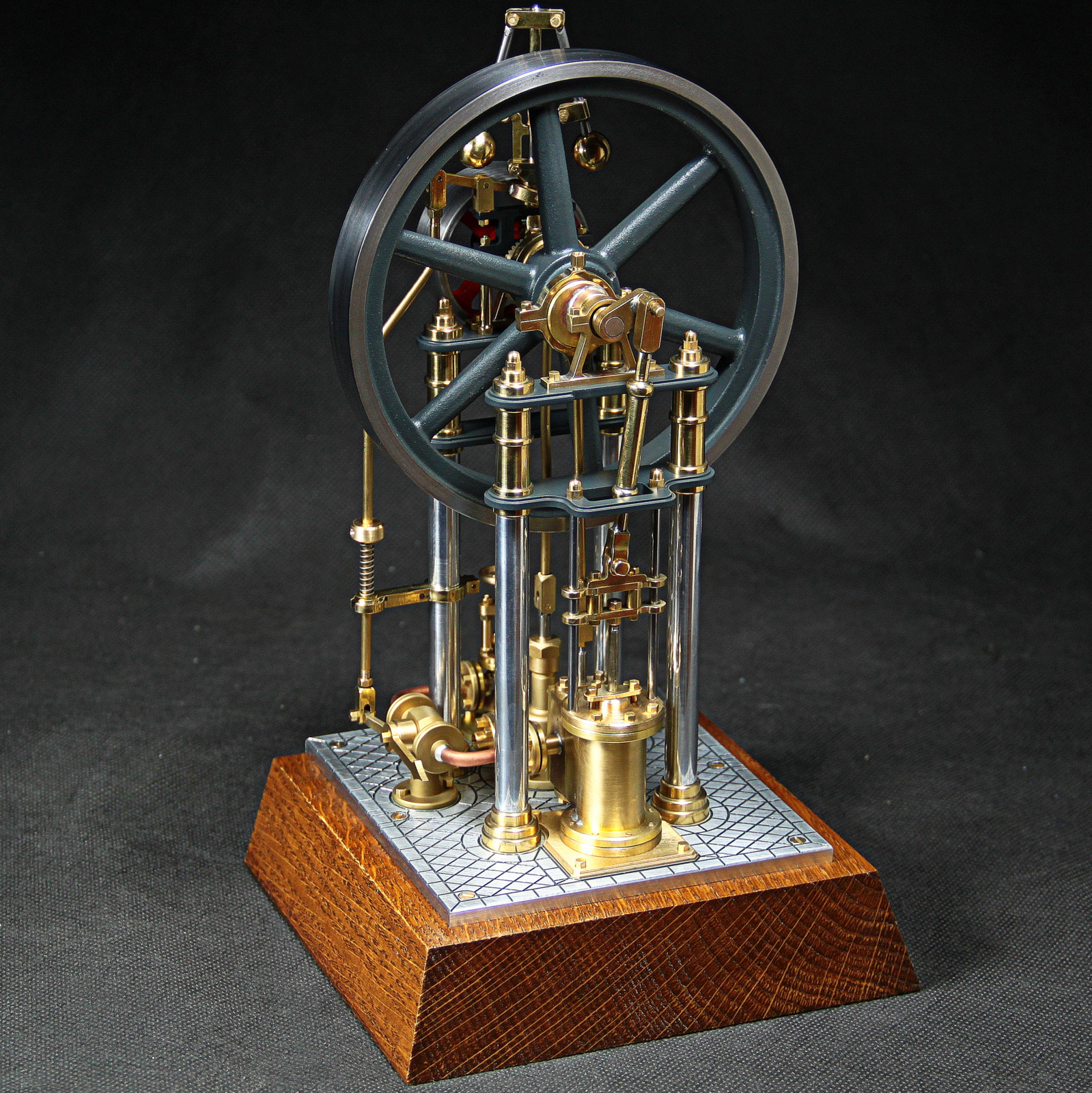

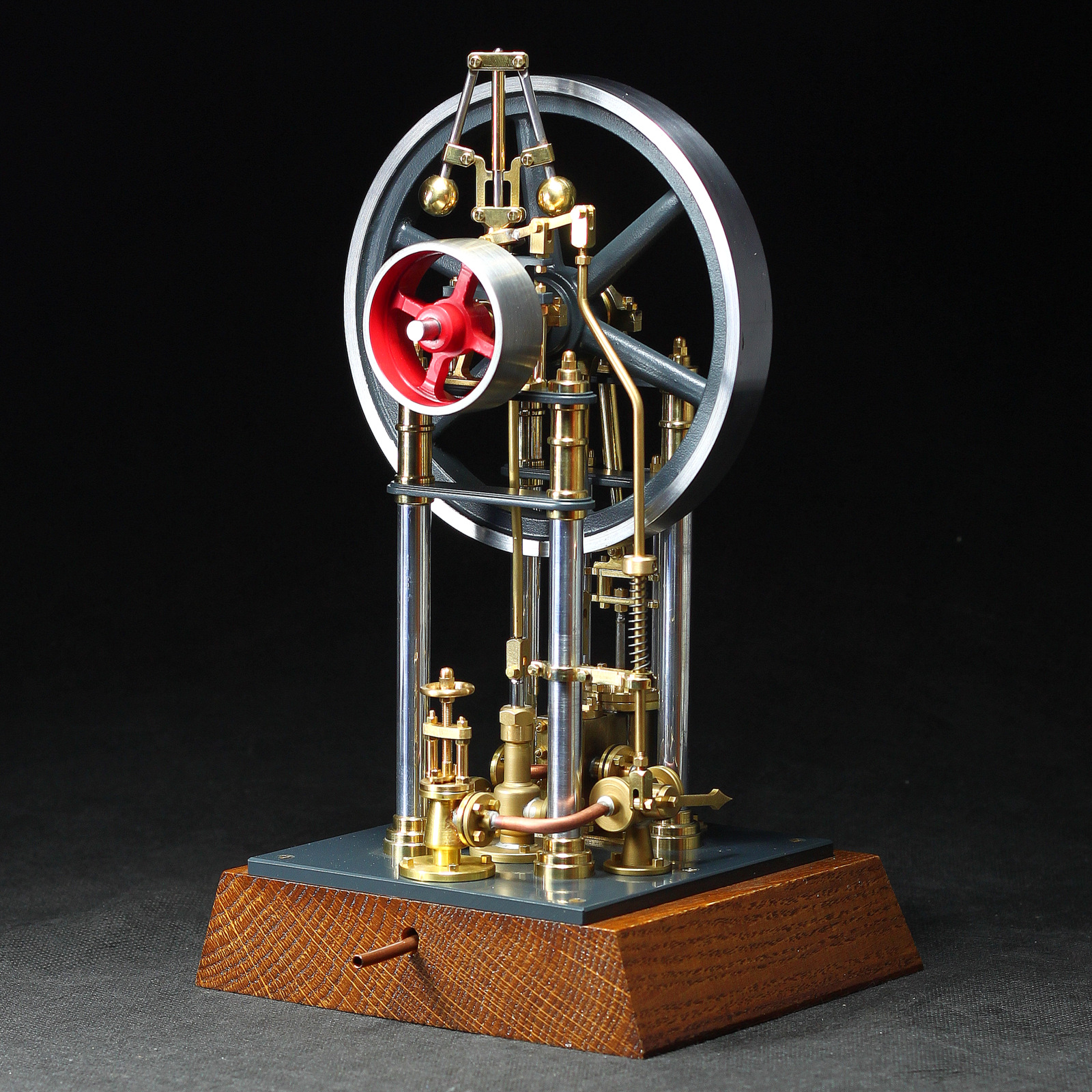

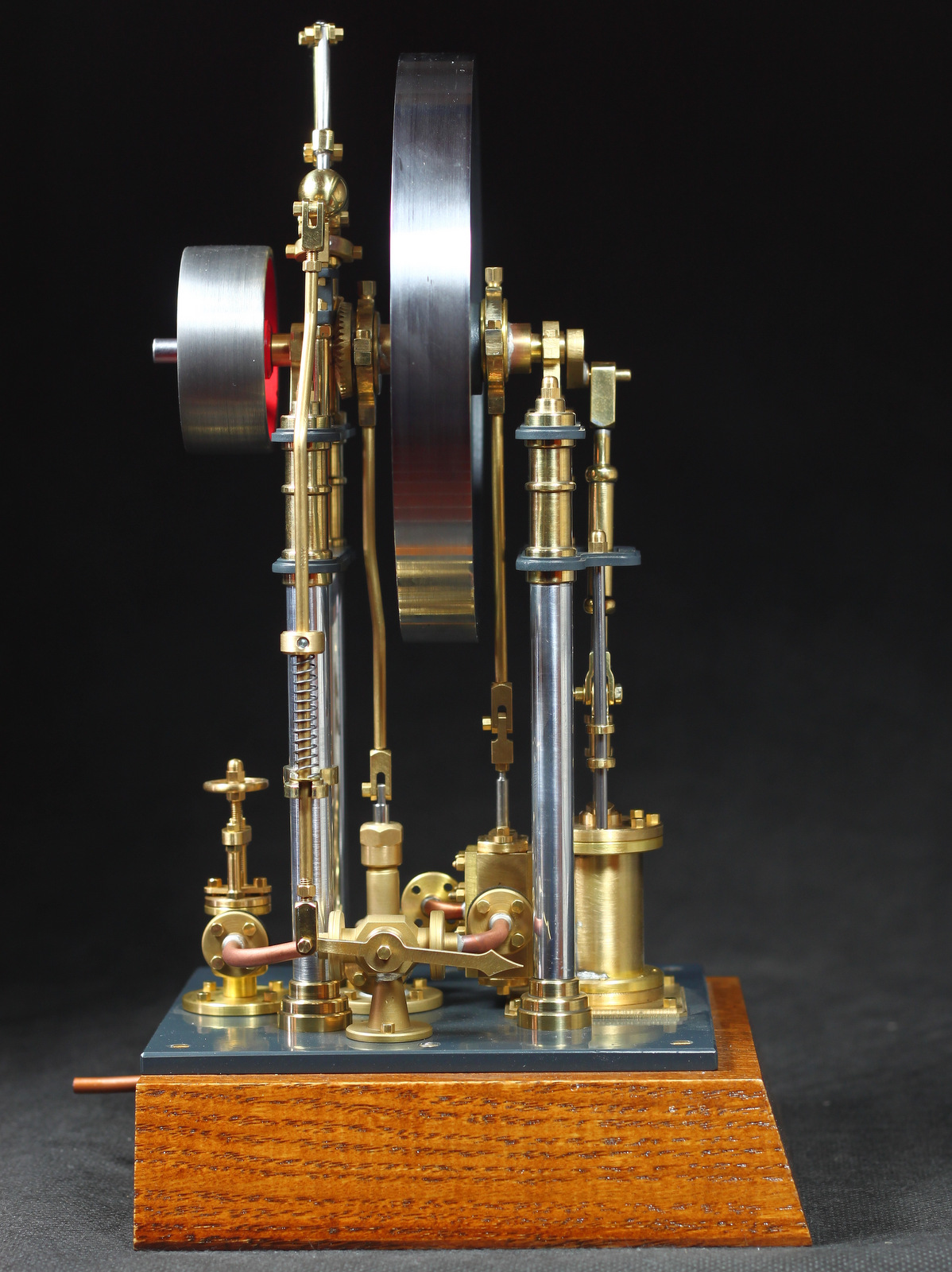

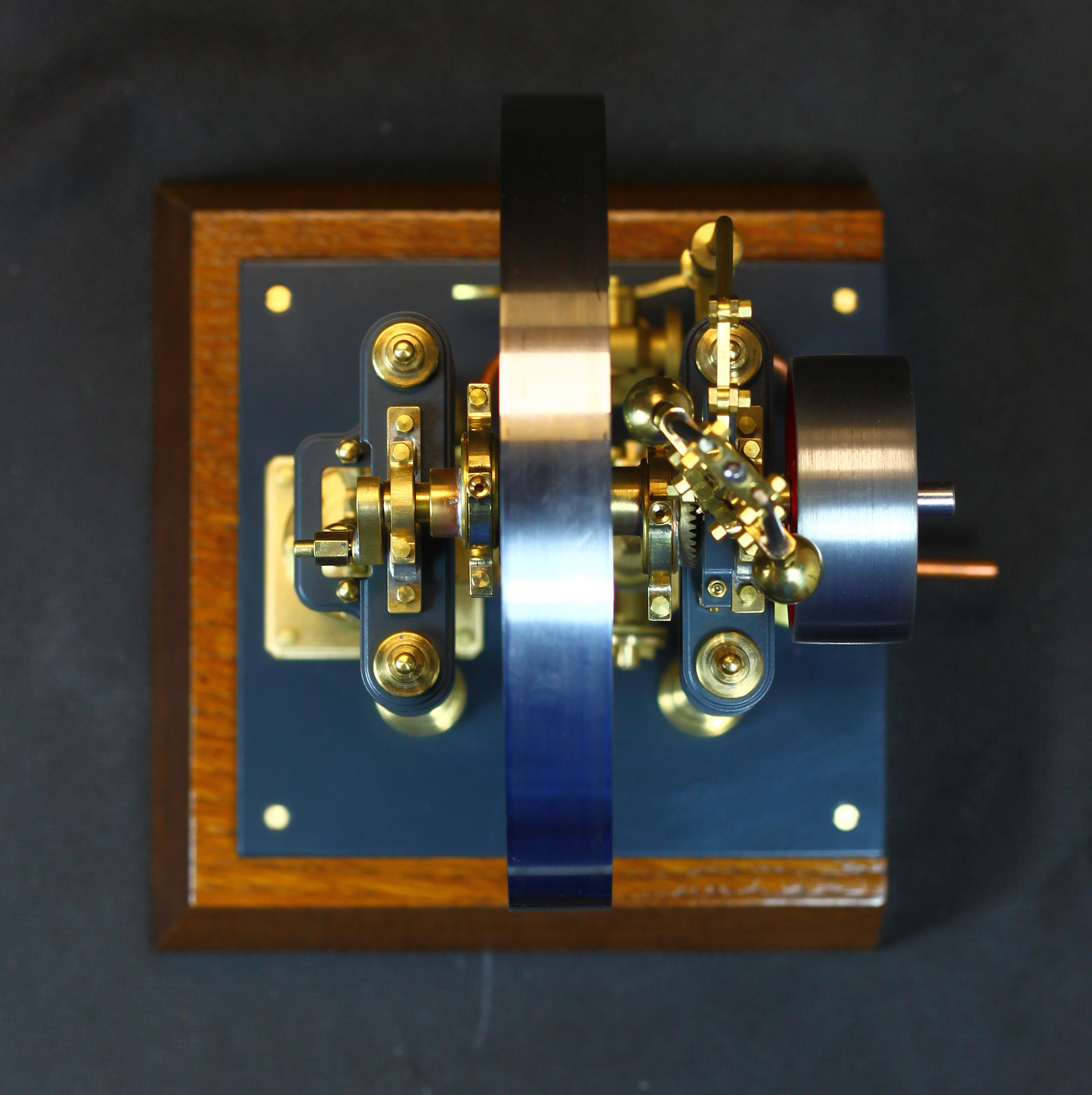

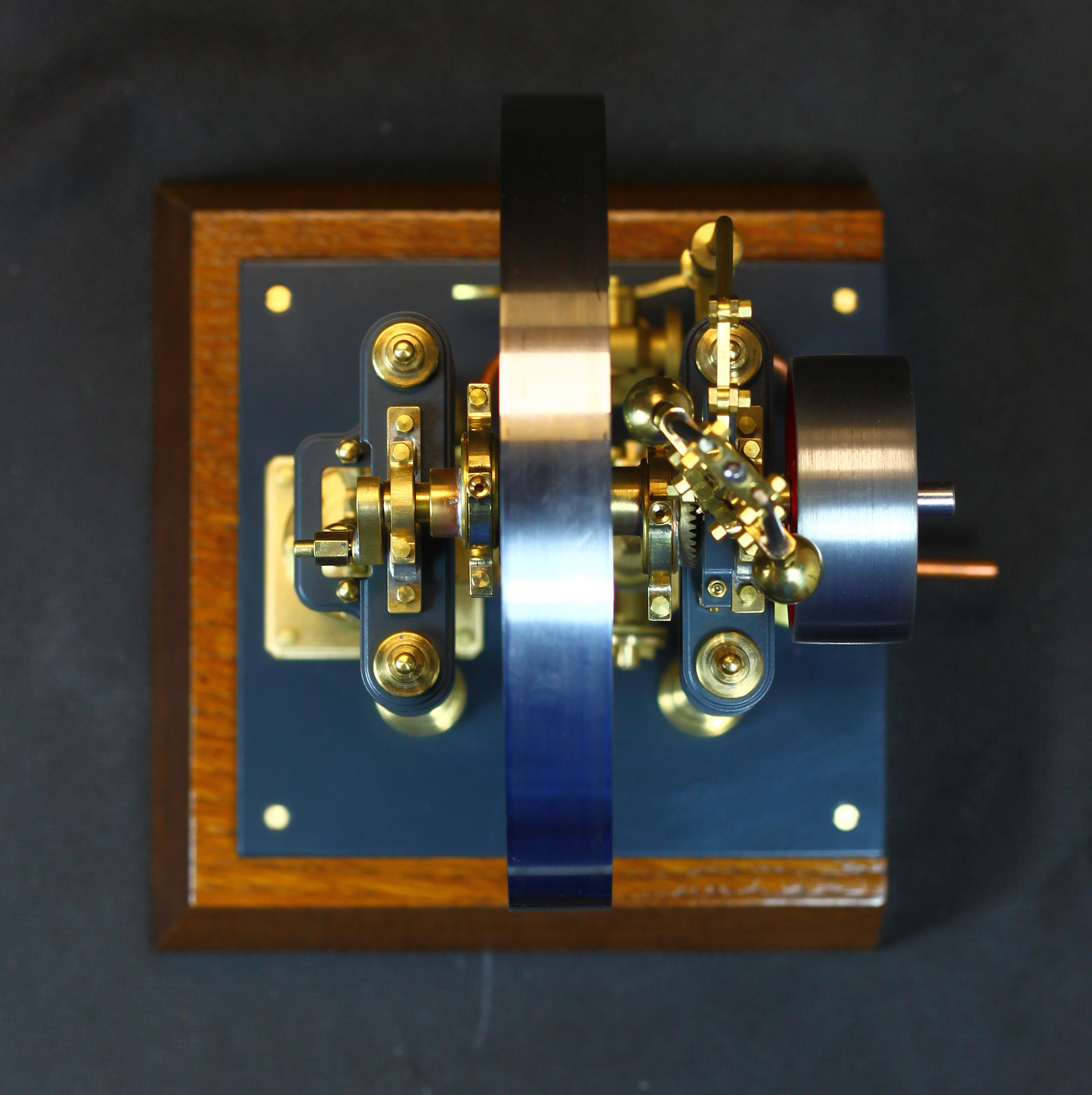

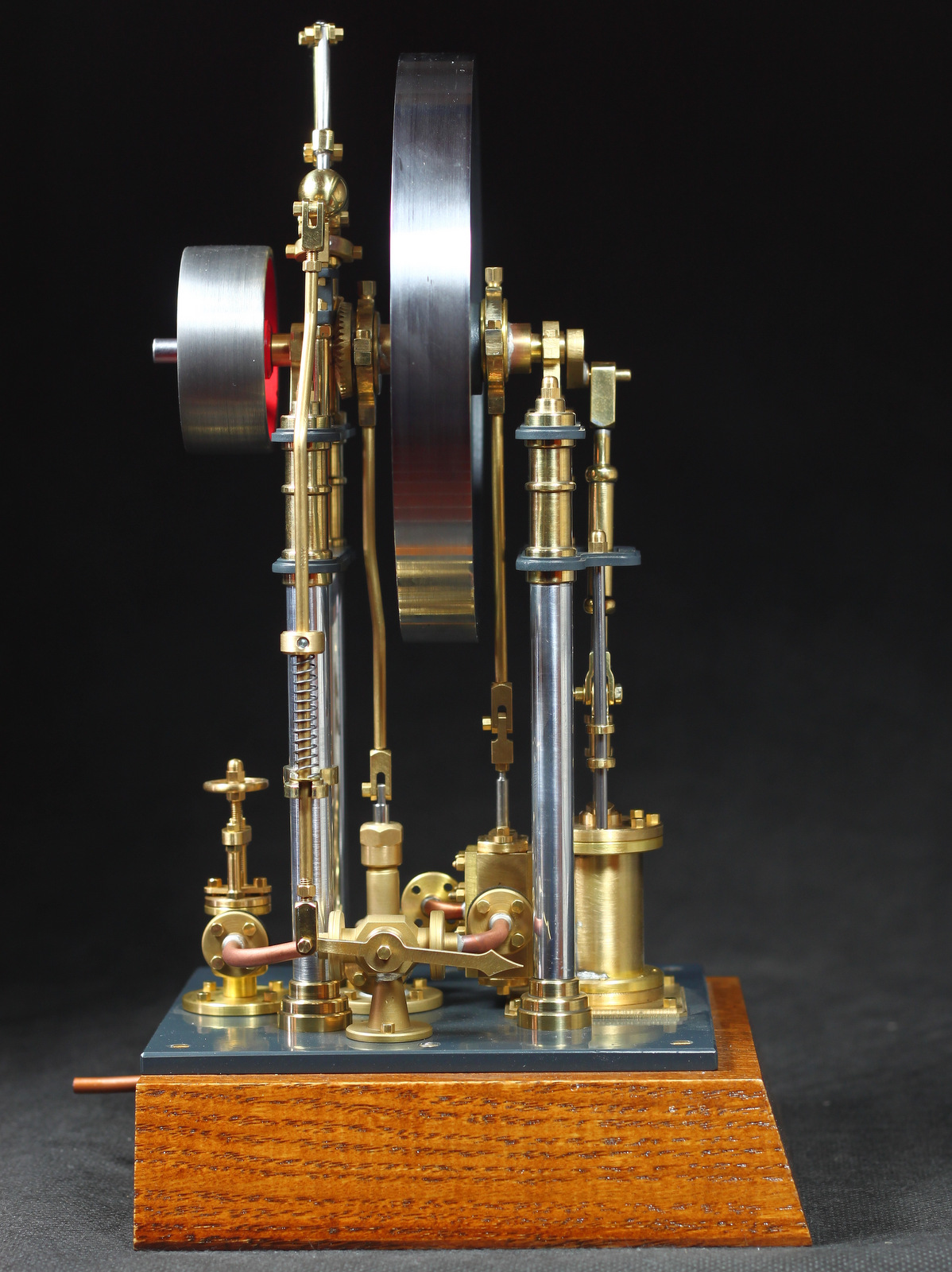

Vertical Column steam engines were relatively widespread in the period from about 1830-1865. The cylinder is located on a flat machine on level ground. The flywheel and the crankshaft are supported in brackets which are supported by columns. The piston rod is straightened over a wide cross head. The speed was often controlled by means of a centrifugal governor. In addition, a feed water pump supplied the boiler with fresh water.

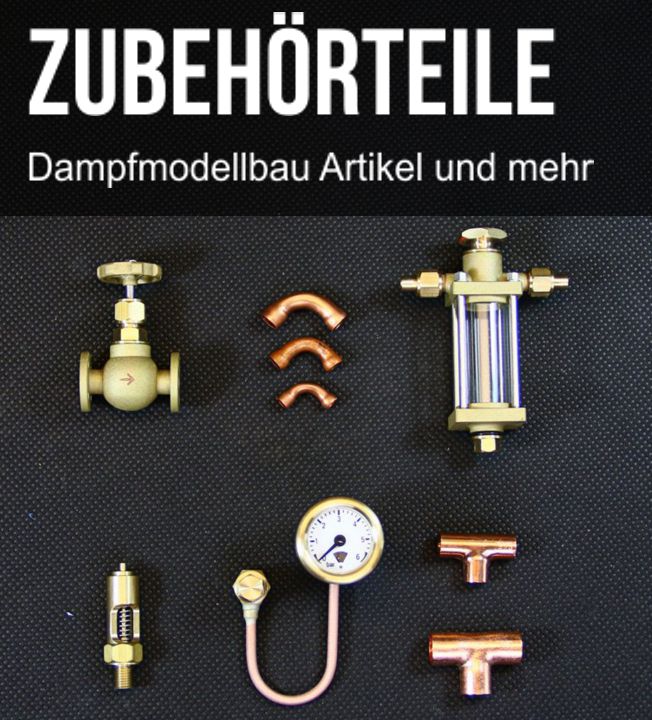

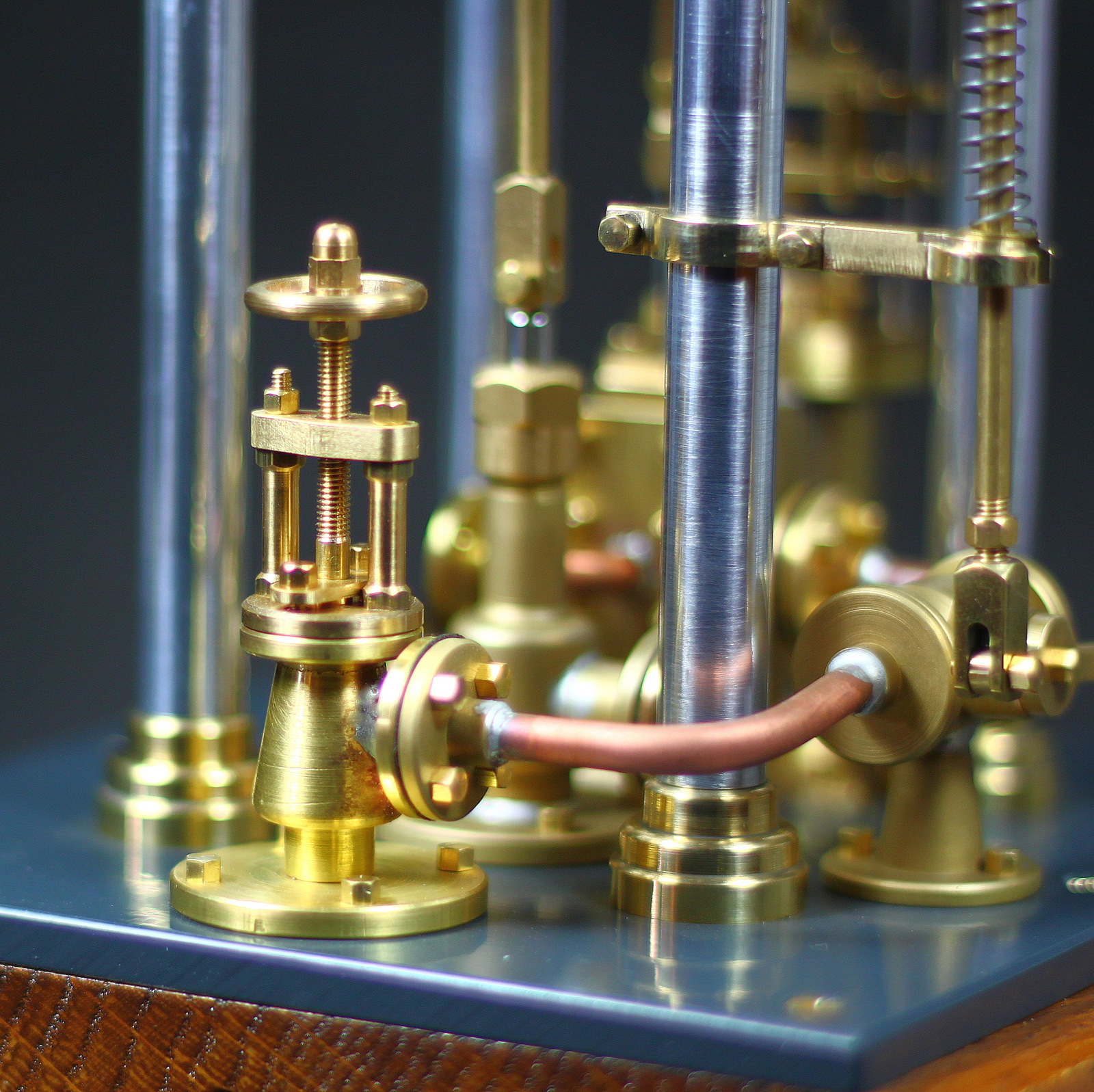

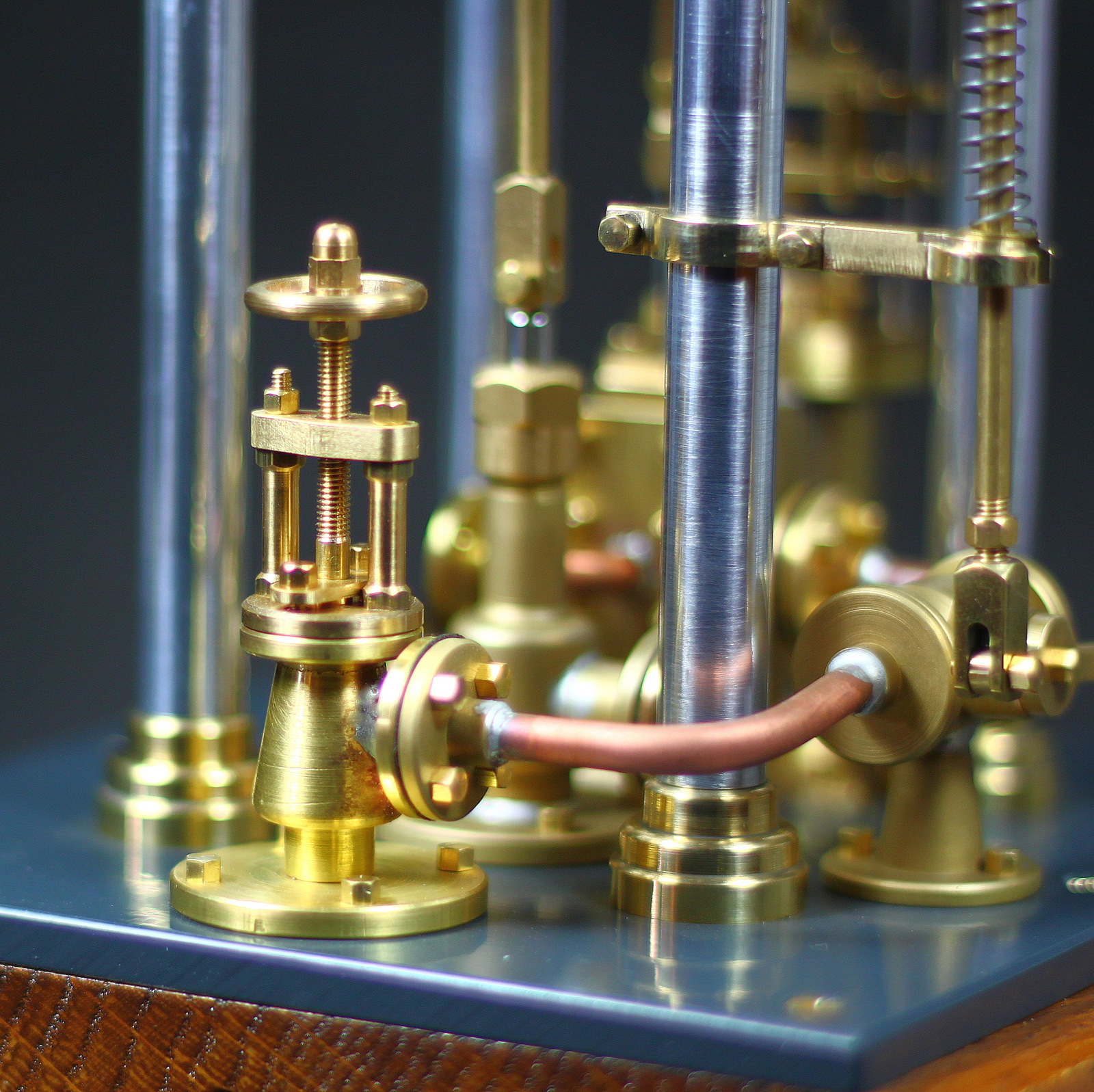

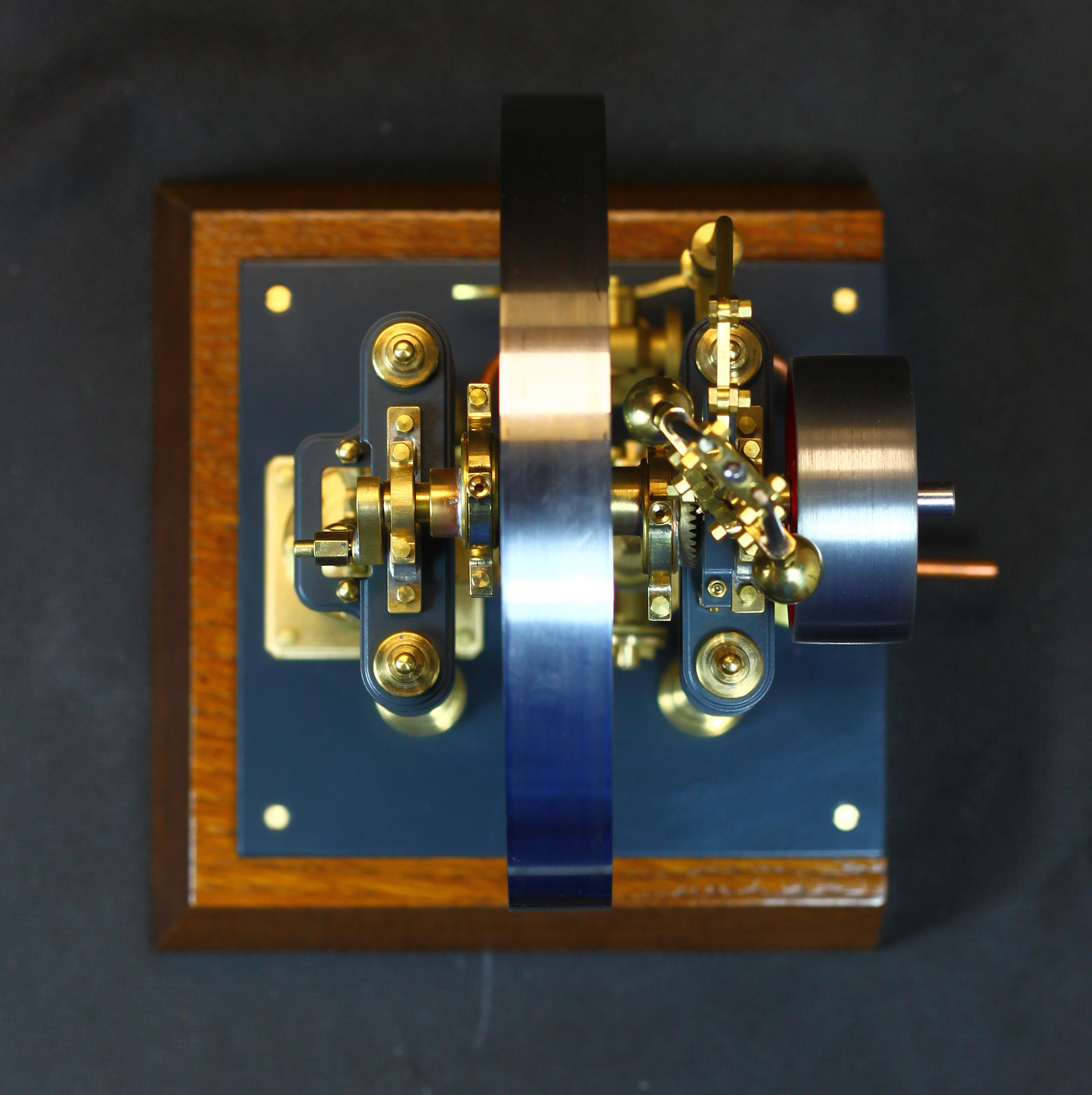

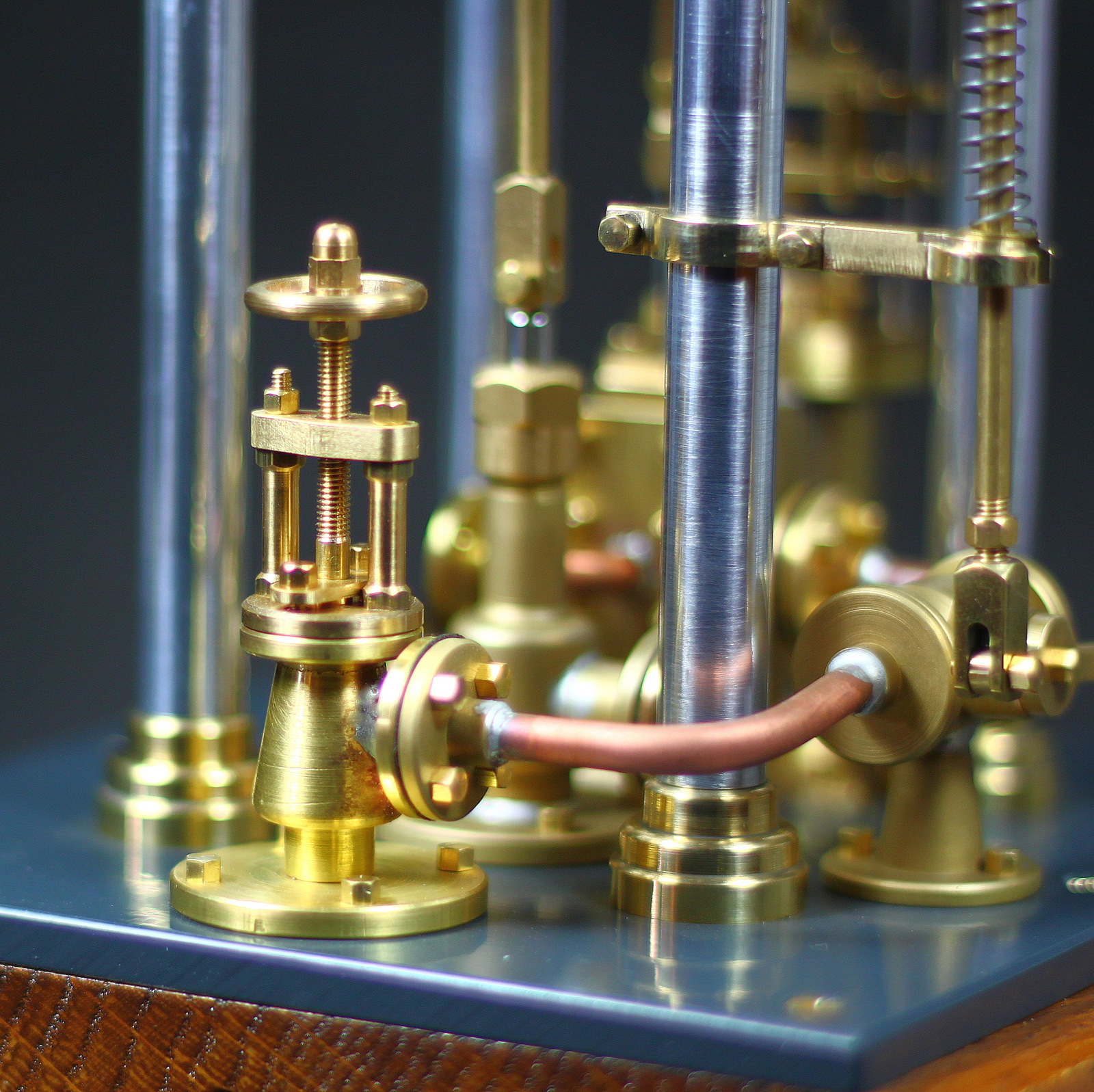

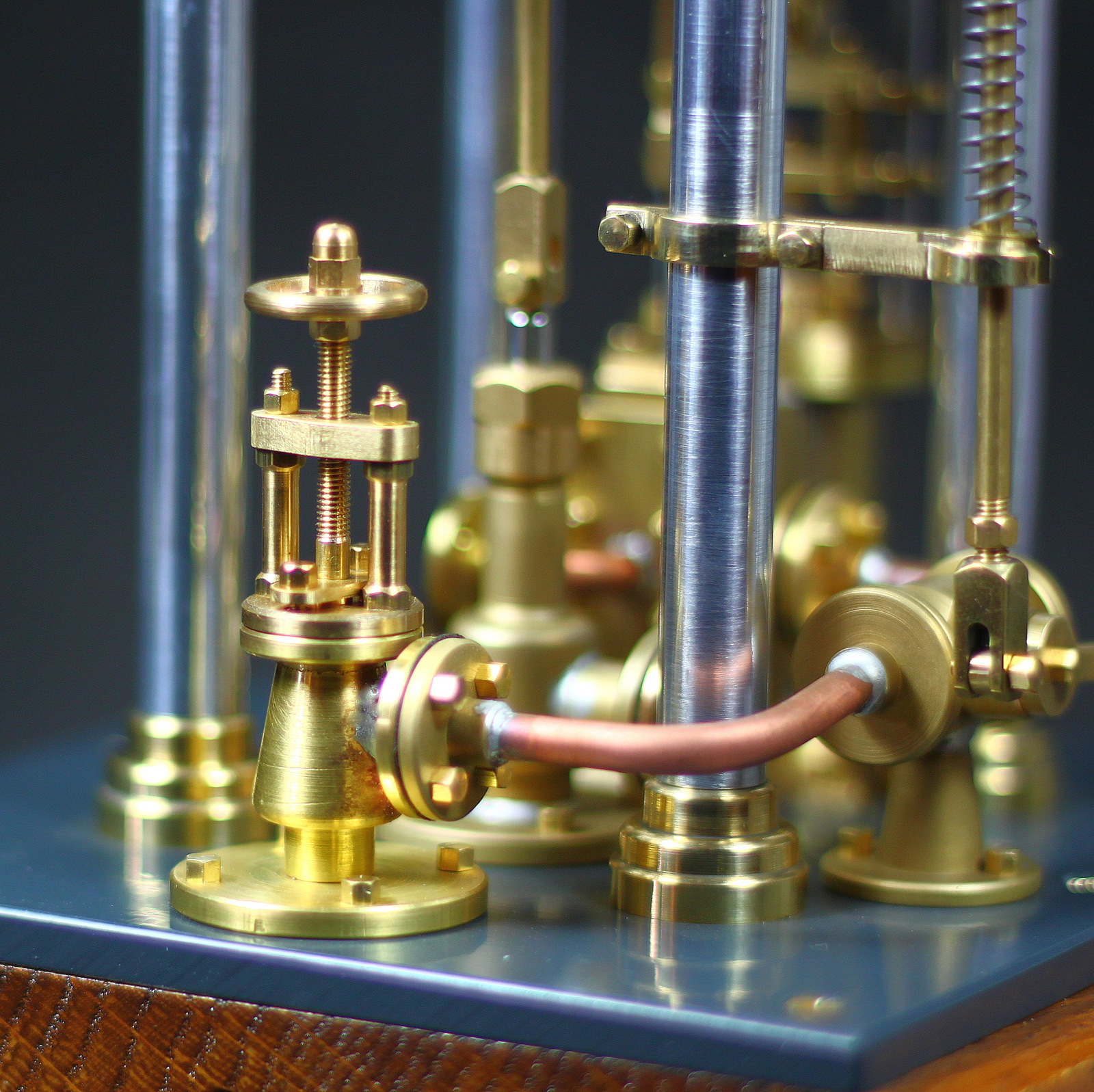

With the material kit for the "Donatus" Vertical Column steam engine, you can build a steam plant yourself. It has all the parts that need a steam system. It has an angle valve with which one can regulate the steam supply. Likewise, the steam engine has a centrifugal regulator, which is driven by bevel gears and controls a control valve via a linkage. The desired speed of the steam engine can be adjusted via a spring and an adjusting ring. A feed water pump is also located on the base plate of the machine. And, of course, not forgetting the heart of the steam system, the beautiful "Donatus" bucking machine. The only thing that is still missing to get this steam system into operation is a suitable boiler or a compressed air connection.

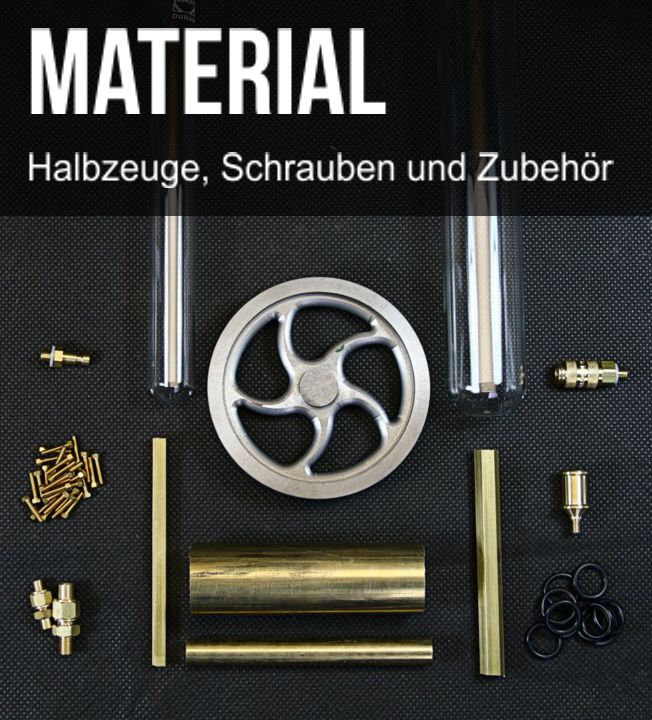

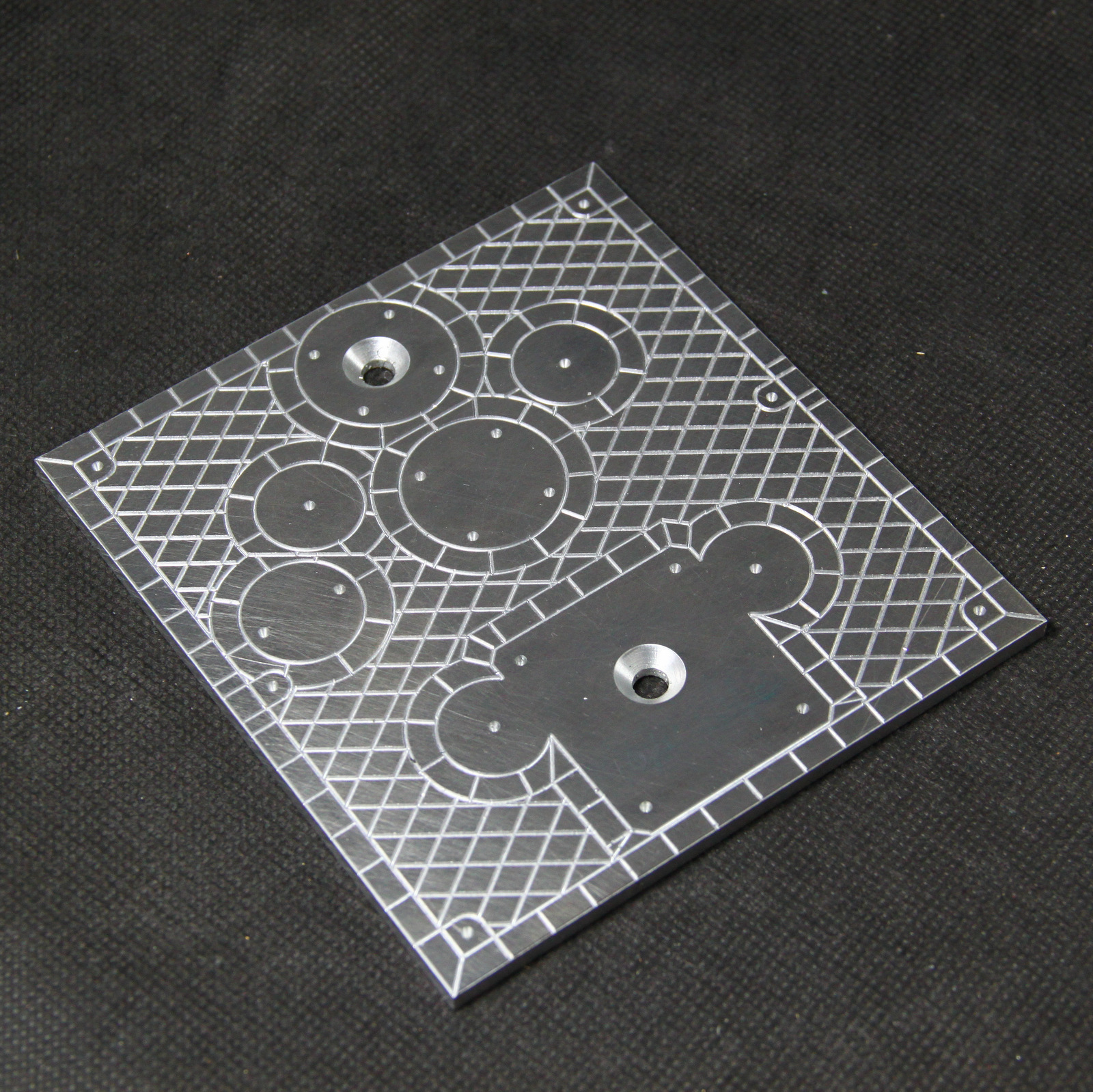

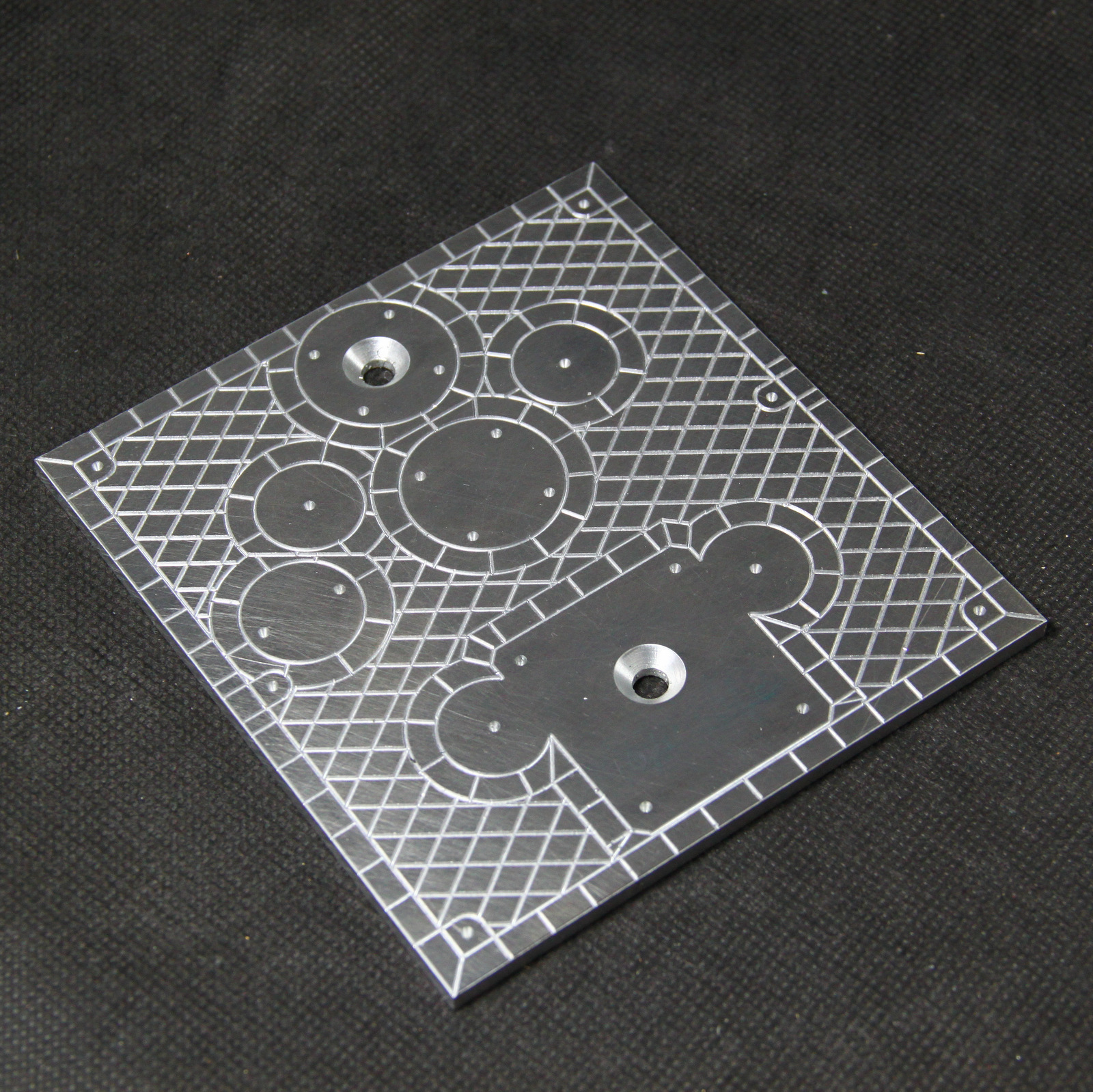

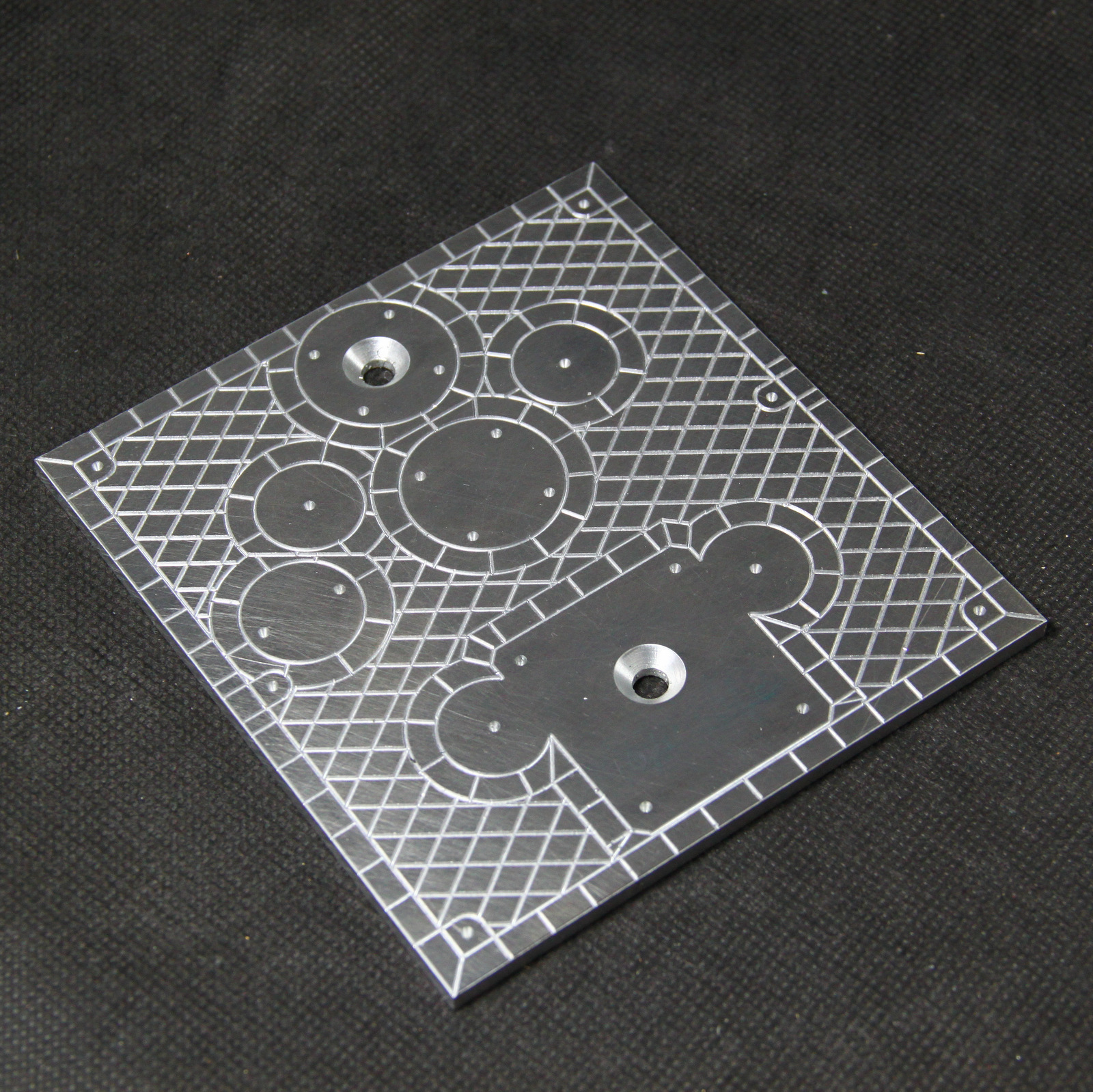

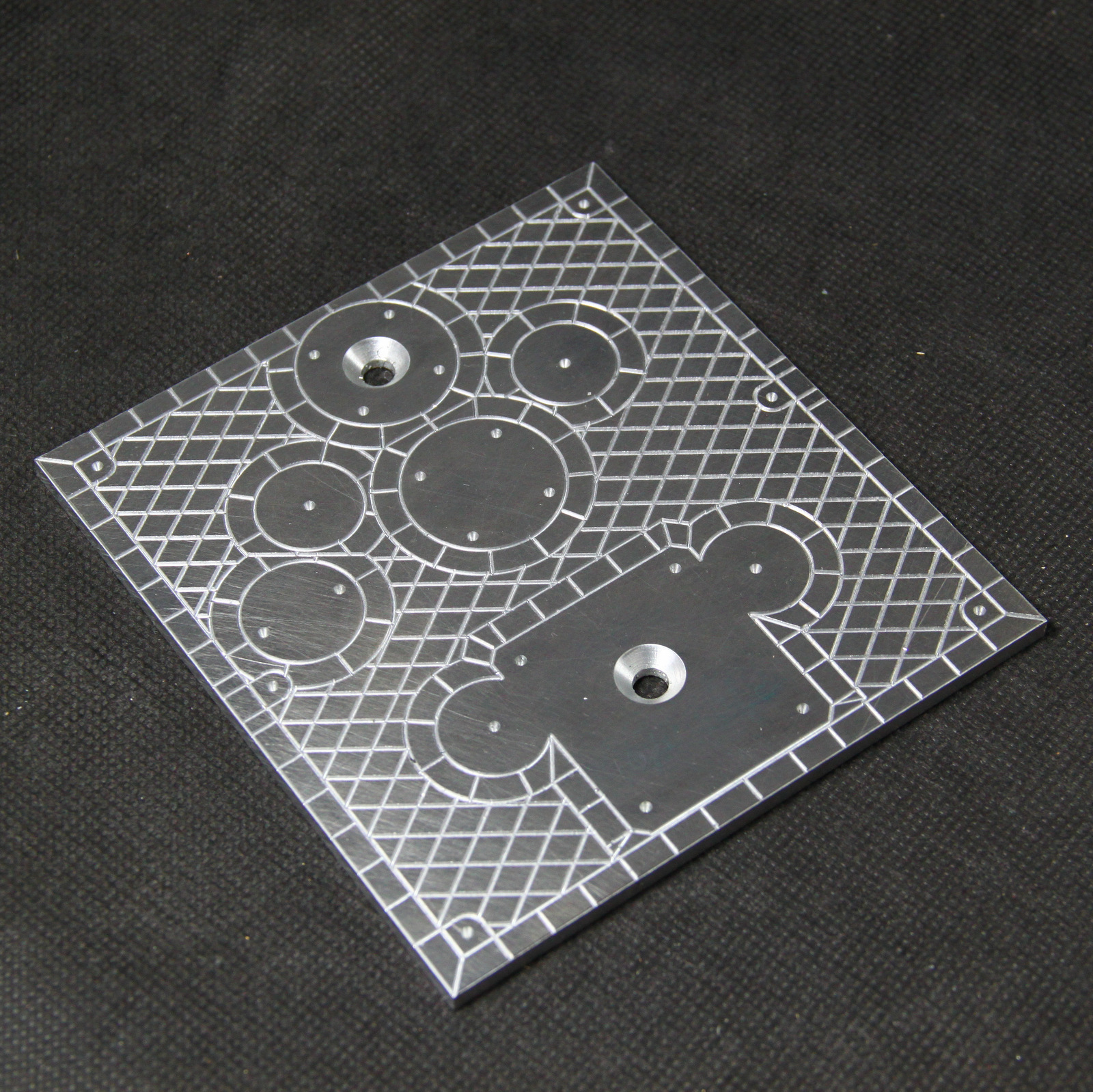

The cylinder of the Vertical Column steam engine is made of brass, the piston and the slide piston are made from bronze. The 140mm flywheel is made of a very clean cast cast steel. For the columns of the steam engine are used aluminum pipes which can be polished perfectly. All other parts are made of brass, as has been proven in steam model construction. The base plate can either be ordered as an unfinished panel blank or with a CNC milled tile pattern.

All materials, screws and accessories required to build the "Donatus" steam engine are included in the kit. All milling parts are prepared so far that they only have to be deburred and possibly drilled.

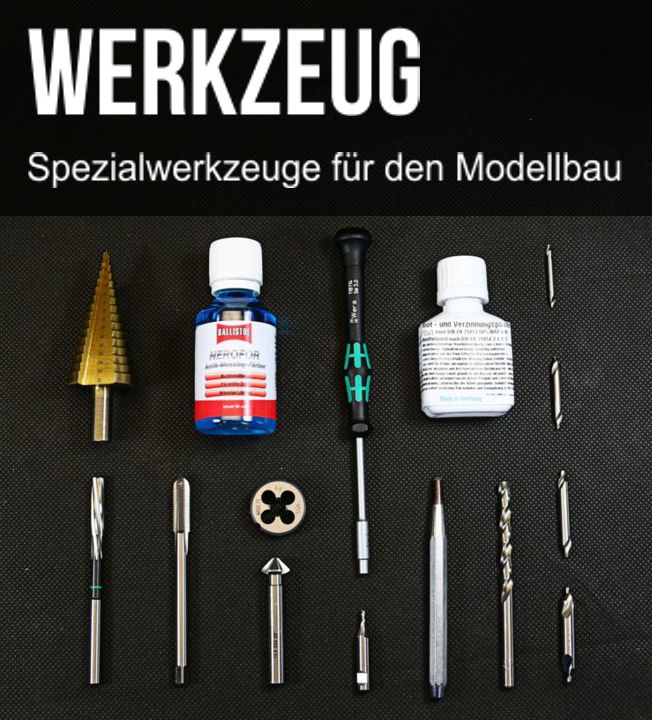

A lathe, a small drill and a gas burner for soldering are required for the construction of the Vertical Column steam engine. In addition, there is still hand tools, which should be in every "steam engine workshop" (taps M2, M3, cutter M2, M3, reamer 3H7, 6H7, 8H7) files and a drill set.

You can find more information on the construction of this steam engine in our model magazine. You will find in our magazine a building report of the "Donatus" Vertical Column steam engine with many pictures and explanatory texts. Thus, you can inform yourself about the construction in advance as well as during the construction phase to find suggestions and support.

Included in the delivery are:

- Finished CNC milled milling parts Raw material

- for the turned parts Raw casting

- for the flywheels Milled and pre-rolled belt pulley

- Machined wooden base plate

- All required screws, model trees, sprockets and ball bearings

- Drawings Column steam engine 'Donatus' (19 sheets) and construction manual (6 sheets)

Dimensions of the "Donatus" model steam engine:

- Height with base plate: 280mm

- Length with base plate: 150mm

- Width with base plate: 160mm

- Diameter of pistons: 16mm

- Flywheel D .: 140mm

You have the choice between the standard aluminum base plate or a very nice aluminum base plate engraved in tile optics. All holes are centered on the engraved base plate.

0 of 0 reviews

Login

Cutsomers also bought