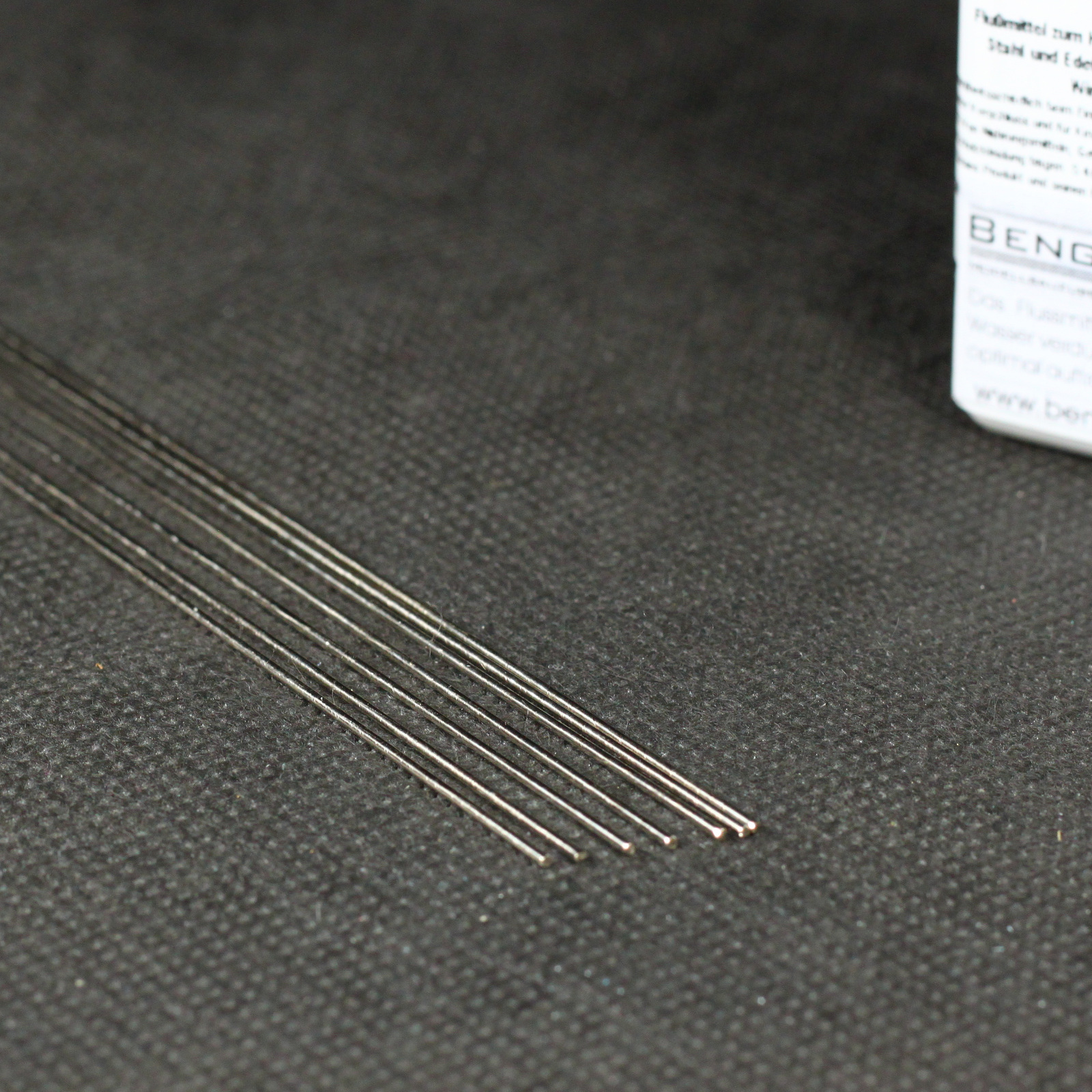

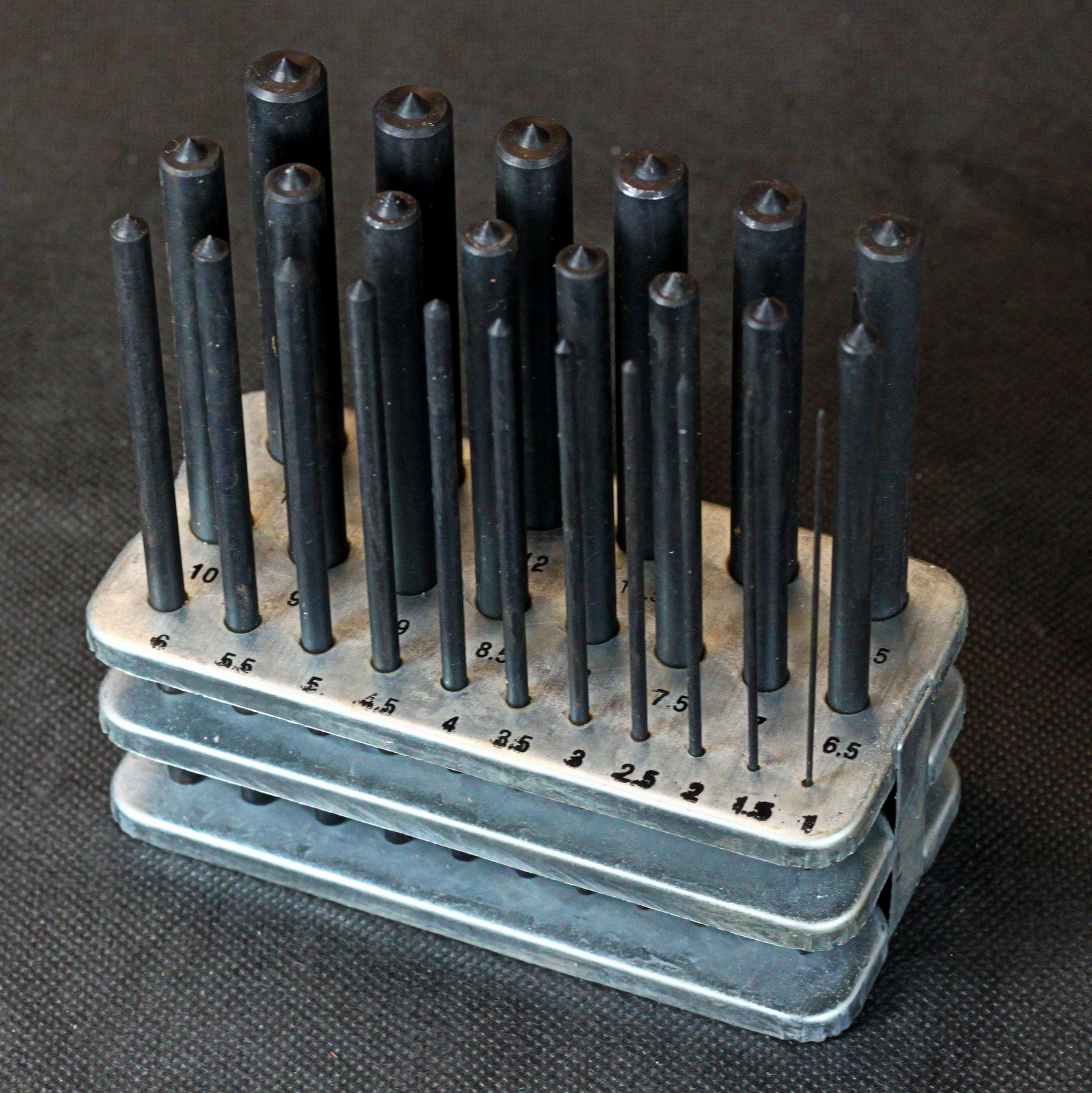

countersink from M3 to M12

Product number:

3493

Product information "countersink from M3 to M12"

Metal cassette with 7 HSS countersinks. The 4-edged flat cores have a fixed guide pin that guides the counterbore in the bore. The 180 ° countersinks are suitable for the production of countersinks in through holes for cylinder screws DIN912 from M3 to M12. The flat shields are delivered in a metal cassette. In order to produce a cylindrical depression, one proceeds as follows. First of all, a drill is produced with a spiral drill, which is 0.1 mm larger than the diameter of the spindle core. Subsequently, the cylindrical countersink is produced with the appropriate countersink while being guided through the bore.

| Schrauben | Senker-Durchmesser | Zapfen-Durchmesser |

| M3 | 6mm | 3,3mm |

| M4 | 8mm | 4,5mm |

| M5 | 10mm | 5,5mm |

| M6 | 11mm | 6,6mm |

| M8 | 15mm | 9mm |

| M10 | 18mm | 11mm |

Login